Nestled in the heart of Zhejiang Province, Jiaxing has emerged as a powerhouse in the realm of handling robot technology, driving transformative changes across industries. This city, known for its robust manufacturing heritage, is now pioneering innovations that redefine how goods are moved, stored, and managed in modern facilities. As global demand for automation surges, Jiaxing's advancements in this field are not just enhancing operational efficiency but also setting new benchmarks for safety and sustainability. The core of this revolution lies in the sophisticated design and deployment of autonomous mobile robots (AMRs) and automated guided vehicles (AGVs), tailored to tackle the unique challenges of high-volume logistics and production environments.

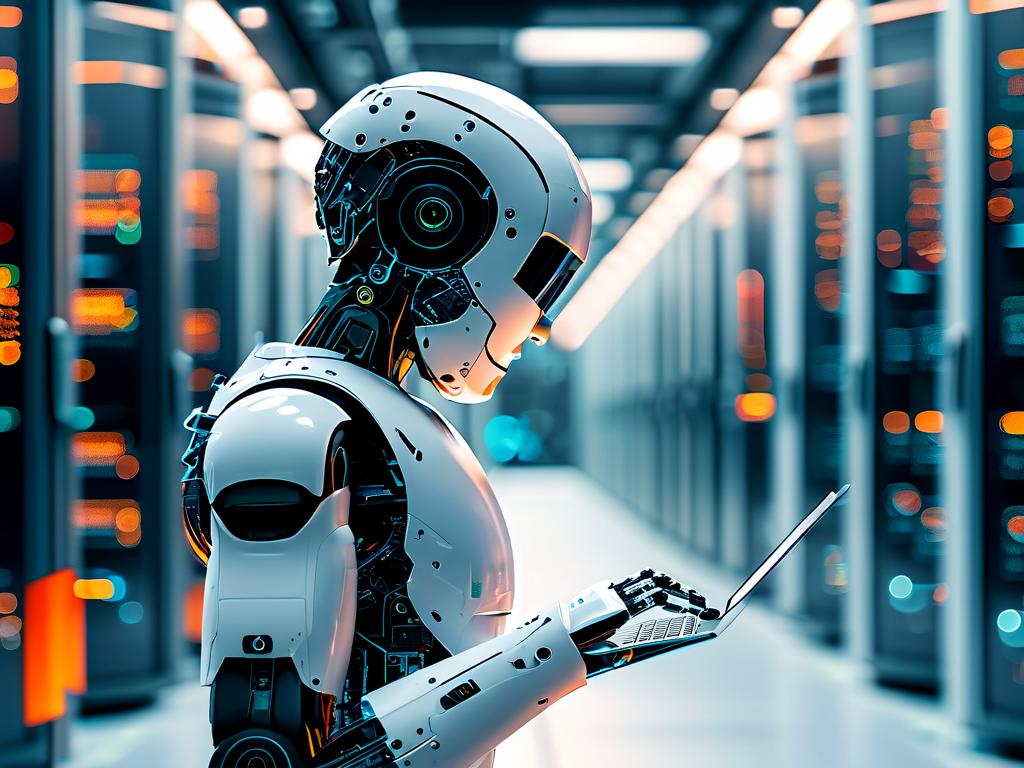

Over the past decade, Jiaxing has cultivated a thriving ecosystem for robotics development, fueled by strategic investments in research hubs and collaborations with top universities. Local firms, such as the forward-thinking RoboMove Inc., have spearheaded breakthroughs in sensor integration and AI-driven navigation systems. These robots can autonomously map warehouses, avoid obstacles in real-time, and optimize routes using advanced algorithms—capabilities that minimize human error and downtime. For instance, in a recent deployment at a major e-commerce fulfillment center in Jiaxing, these robots slashed handling times by 40% while reducing accident rates significantly. This isn't just about replacing manual labor; it's about augmenting human capabilities, allowing workers to focus on higher-value tasks while robots handle the heavy lifting.

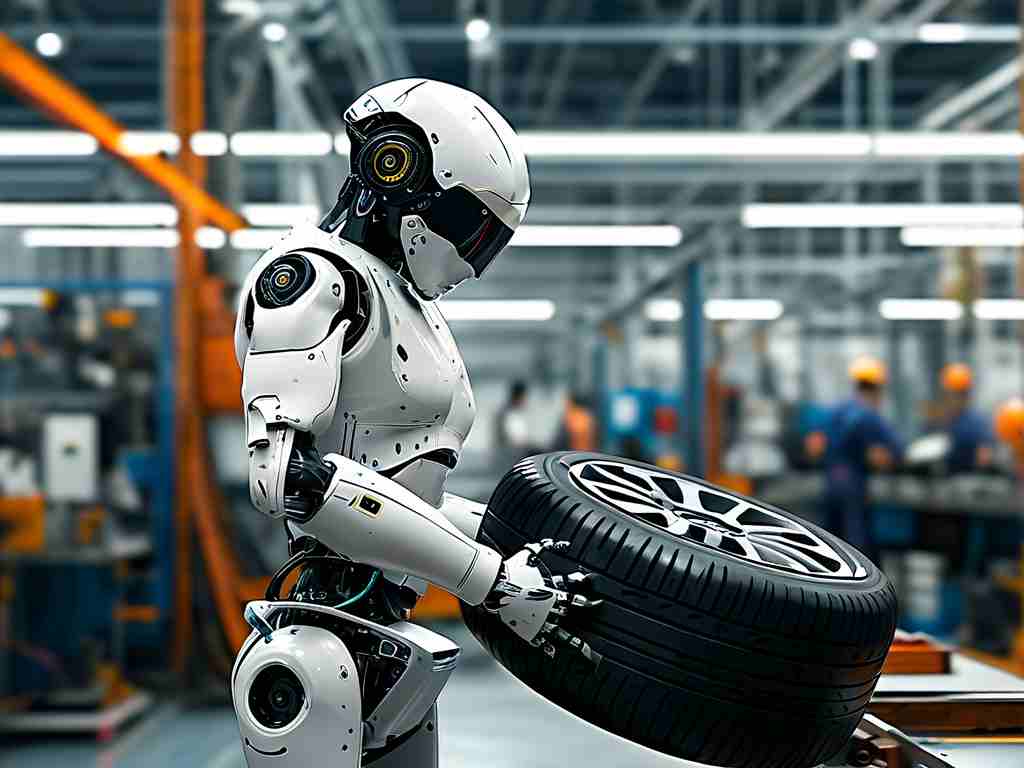

The applications of Jiaxing's handling robot technology extend far beyond warehousing. In automotive manufacturing plants, these robots streamline assembly lines by transporting components with precision, ensuring just-in-time delivery that boosts throughput. Similarly, in the food and beverage sector, they maintain hygienic standards by operating in controlled environments without contamination risks. One compelling case study involves a local pharmaceutical company that integrated Jiaxing-developed AMRs to manage sensitive drug inventories. The robots' ability to operate 24/7 in temperature-controlled zones has not only cut costs but also improved compliance with stringent regulatory requirements. Such versatility underscores why industries worldwide are turning to Jiaxing for scalable, adaptable solutions.

However, the journey hasn't been without hurdles. Initial adoption faced resistance due to high upfront costs and integration complexities with existing infrastructure. Companies had to navigate challenges like retrofitting old facilities and training staff to work alongside these intelligent machines. Yet, through iterative improvements and government-backed incentives, Jiaxing's tech community has addressed these issues. Innovations in modular designs now allow for easier upgrades, while cloud-based management platforms provide real-time analytics for predictive maintenance. This proactive approach reduces total ownership costs and accelerates return on investment, making the technology accessible even for small and medium enterprises.

Looking ahead, the future of Jiaxing's handling robot technology is poised for exponential growth, driven by trends like the Internet of Things (IoT) and machine learning. Experts predict that by 2030, these robots will evolve to handle more complex tasks, such as collaborative manipulation in dynamic settings, thanks to enhanced AI models trained on vast datasets. Moreover, sustainability is becoming a key focus, with Jiaxing firms developing energy-efficient models that lower carbon footprints—a critical step as industries prioritize green initiatives. As this tech matures, it could revolutionize global supply chains, making them more resilient against disruptions like pandemics or geopolitical shifts.

In , Jiaxing's leadership in handling robot technology is reshaping the industrial landscape, offering smarter, safer, and more efficient ways to manage material flow. Its blend of innovation, practical application, and forward-thinking strategies positions it as a global model for automation excellence. For businesses seeking competitive edges, embracing these advancements isn't just an option—it's a necessity in the fast-paced world of modern logistics and manufacturing.