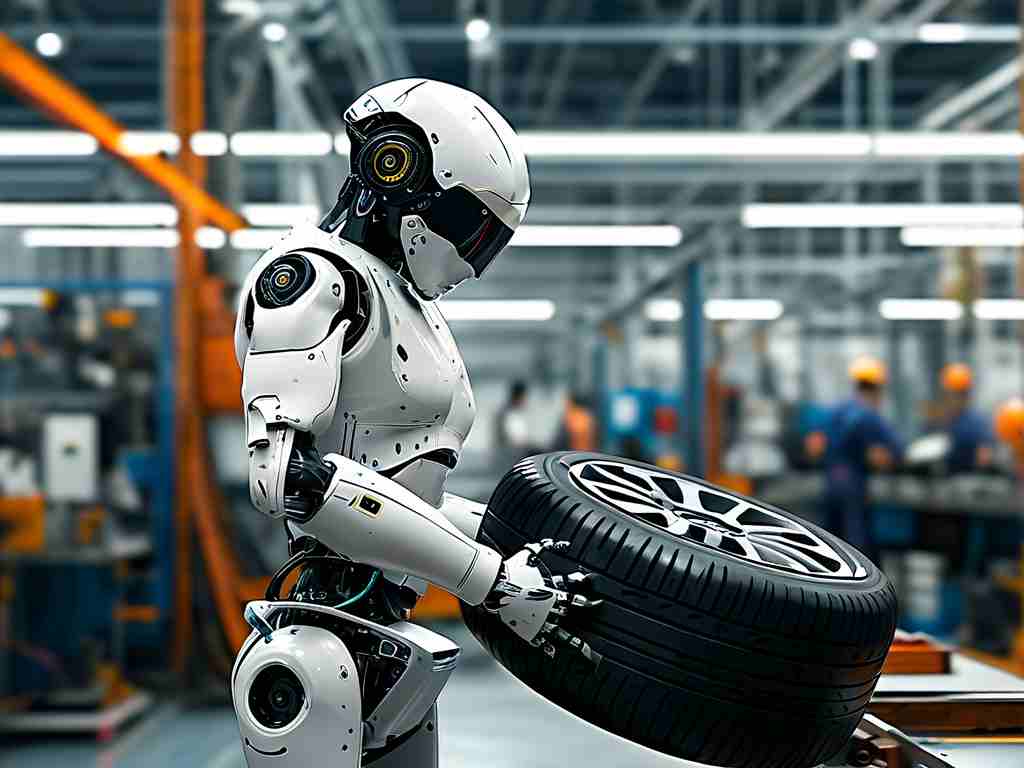

The landscape of industrial automation is undergoing a seismic shift thanks to advancements like Dazhuang robot manufacturing technology, which stands at the forefront of modern engineering. This innovative approach combines artificial intelligence, precision mechanics, and sustainable practices to redefine how robots are built and deployed across global industries. Unlike traditional methods that rely on manual assembly and outdated systems, Dazhuang's methodology emphasizes modular design, where components are pre-fabricated using advanced 3D printing and laser-cutting techniques. This not only accelerates production timelines but also enhances reliability, reducing error rates by up to 40% in high-stakes environments such as automotive assembly lines or electronics fabrication. As companies worldwide grapple with labor shortages and rising costs, Dazhuang's solutions offer a lifeline, enabling scalable automation that adapts to diverse operational needs without compromising on quality or safety standards.

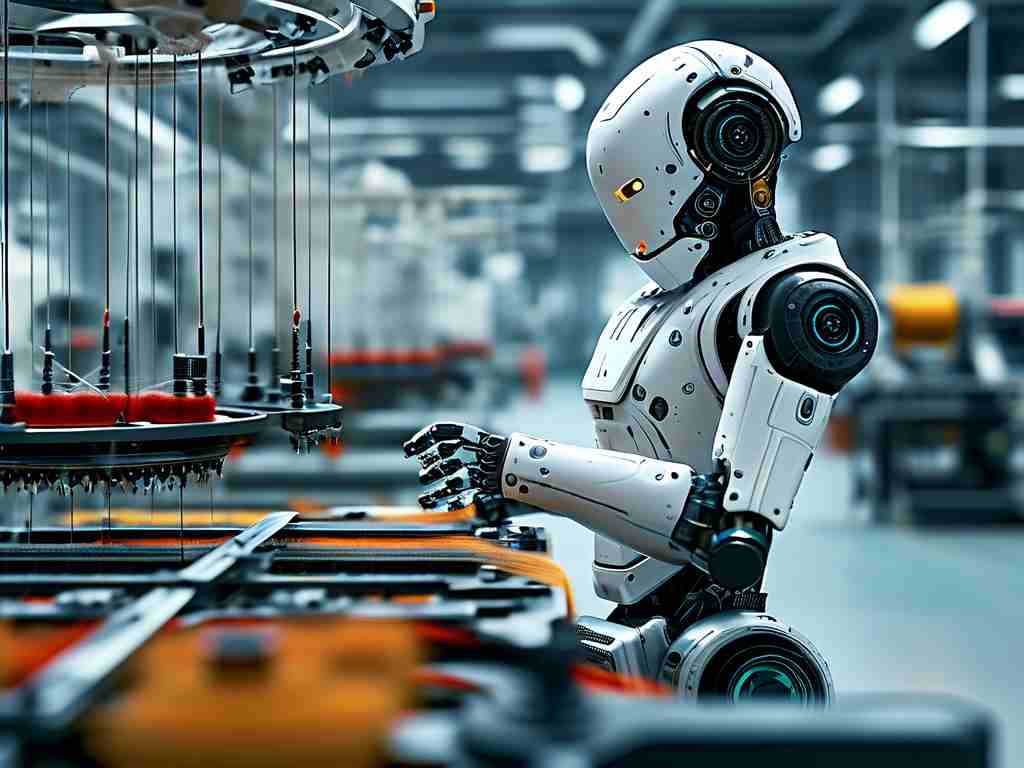

One of the core strengths of Dazhuang robot manufacturing lies in its integration of AI-driven predictive analytics. By embedding sensors and machine learning algorithms into the manufacturing process, the system continuously monitors variables like temperature, pressure, and material stress. This real-time data allows for proactive adjustments, preventing potential failures and extending the lifespan of robotic units. For instance, in a recent pilot project with a major logistics firm, Dazhuang's robots demonstrated a 30% increase in operational efficiency by autonomously optimizing warehouse workflows. Such applications highlight the versatility of this technology, which spans sectors from healthcare—where surgical robots require micron-level precision—to agriculture, where automated harvesters boost yields while minimizing environmental impact. Moreover, the emphasis on energy efficiency sets Dazhuang apart; their robots consume 25% less power than competitors, leveraging regenerative braking and solar-compatible designs to support green initiatives. This holistic approach not only cuts operational expenses but also aligns with global sustainability goals, making it a preferred choice for forward-thinking enterprises.

Beyond immediate benefits, Dazhuang's manufacturing innovations are shaping the future of human-robot collaboration. The technology incorporates intuitive interfaces and collaborative robotics (cobots) that allow seamless interaction with human workers. For example, in smart factories, cobots equipped with Dazhuang's adaptive learning capabilities can perform complex tasks like quality inspection or delicate assembly without constant supervision, fostering a safer and more productive work environment. This evolution addresses common concerns about job displacement by creating new roles in robot maintenance and programming, thus driving economic growth. Looking ahead, Dazhuang is pioneering developments in swarm robotics, where fleets of small, interconnected units collaborate on large-scale projects, from disaster response to urban infrastructure development. Challenges remain, such as ensuring cybersecurity in interconnected systems and scaling production to meet surging demand, but ongoing research promises breakthroughs. Ultimately, Dazhuang robot manufacturing technology isn't just a tool—it's a transformative force that empowers industries to innovate, compete, and thrive in an increasingly automated world, paving the way for a smarter, more resilient future.