The automotive industry has witnessed groundbreaking advancements with the integration of robotics into routine maintenance tasks. One such innovation is robotic tire replacement technology, which combines precision engineering, artificial intelligence, and adaptive mechanics to redefine how vehicles are serviced. This article explores the mechanics, benefits, and challenges of this emerging technology while highlighting its potential to transform automotive care.

How Robotic Tire Replacement Works

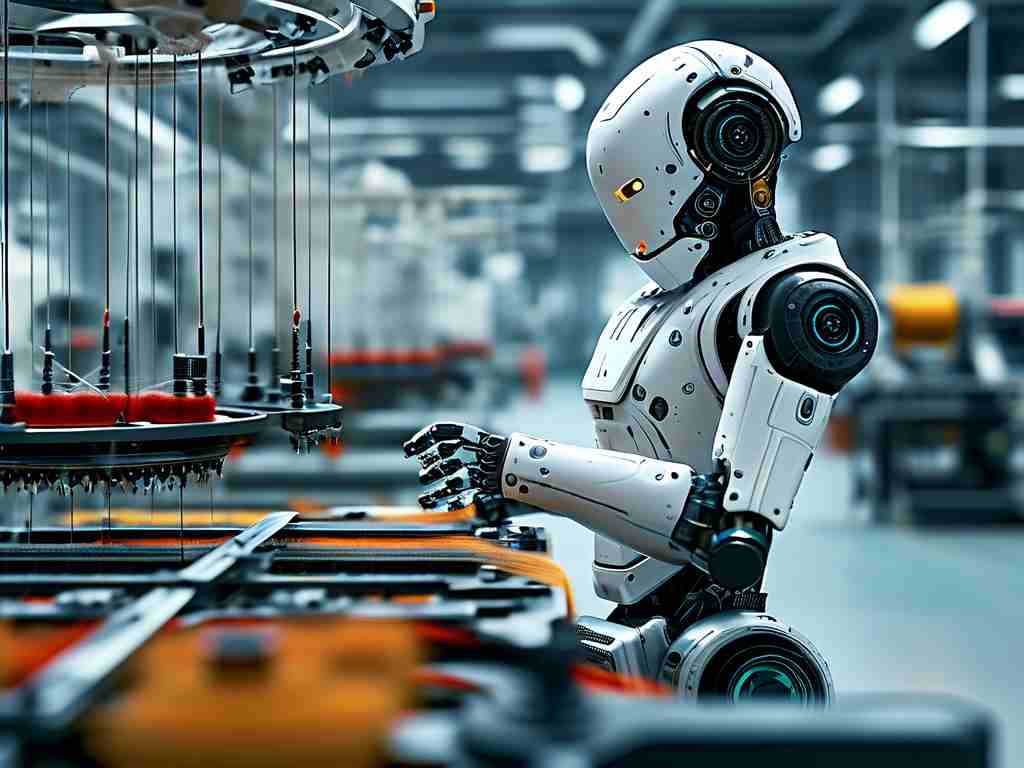

Robotic tire replacement systems rely on a combination of hardware and software to perform tasks traditionally handled by human technicians. Equipped with multi-axis robotic arms, these machines use vision sensors and machine learning algorithms to identify tire specifications, locate lug nuts, and align tools with millimeter accuracy. For example, a robotic arm might scan a wheel’s bolt pattern using 3D imaging, calculate torque requirements based on vehicle data, and execute rotations with controlled force to remove or fasten nuts. Advanced models even incorporate haptic feedback to adjust grip strength when handling delicate alloy rims.

The process begins with the vehicle being positioned on a lift platform, where laser-guided systems map its dimensions. Once the robot identifies the target wheel, it deploys specialized end-effectors—tools designed for lifting jacks, removing hubcaps, or operating impact wrenches. Some systems integrate autonomous mobility, allowing robots to navigate around the vehicle without human guidance.

Advantages Over Manual Labor

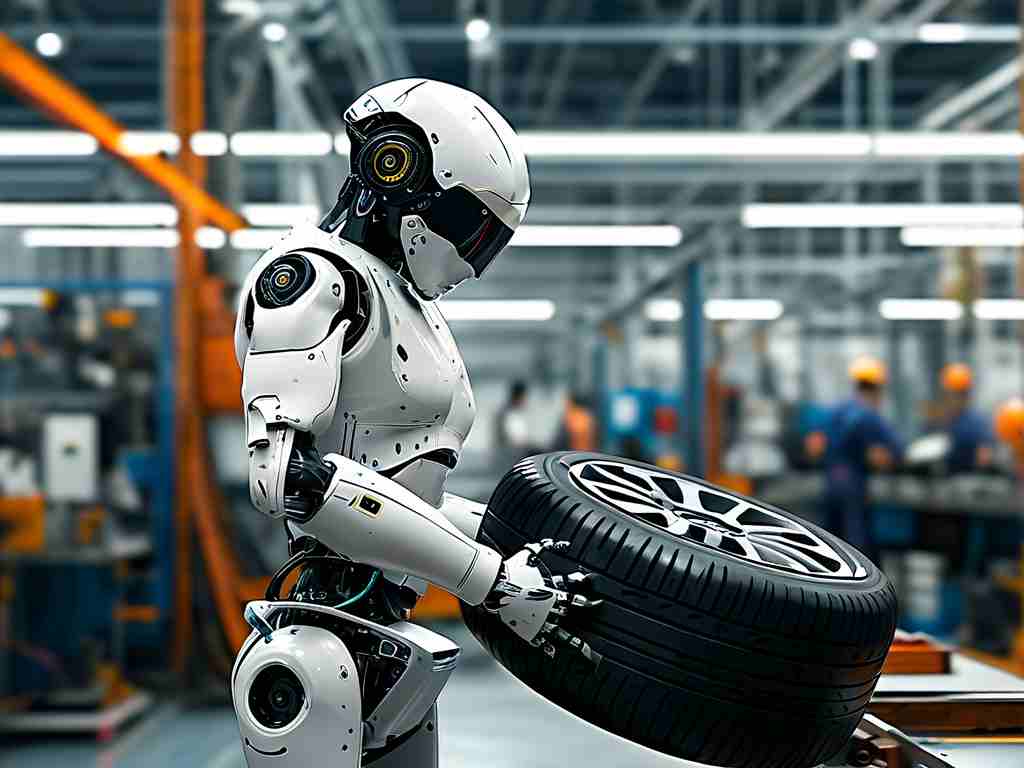

Speed and consistency are two standout benefits of robotic tire replacement. A well-calibrated robot can swap a tire in under five minutes, a task that might take a human technician twice as long. This efficiency is particularly valuable for high-volume settings like racing pits or fleet maintenance centers. During endurance races, teams using robotic systems have reported sub-3-minute tire changes, minimizing downtime and maximizing track performance.

Safety is another critical advantage. Robots eliminate risks associated with heavy lifting, exposure to hydraulic fluids, or accidental tool slippage. In harsh environments—such as icy roads or mining sites—automated systems reduce the need for human workers to operate in hazardous conditions. Additionally, robotic precision minimizes the likelihood of cross-threaded lug nuts or uneven torque distribution, which can lead to wheel detachment accidents.

Challenges and Limitations

Despite its promise, robotic tire replacement faces technical and logistical hurdles. One major obstacle is the variability in vehicle designs. A system trained on sedans may struggle with trucks due to differences in wheel size, weight, or suspension height. To address this, developers are creating modular robots with swappable toolkits and AI models trained on diverse datasets.

Cost remains another barrier. Initial investments for robotic systems range from $200,000 to $500,000, making them impractical for small repair shops. However, companies like RoboTire and Tesla are exploring subscription-based models to democratize access. Maintenance complexity is also a concern; robots require regular calibration and software updates to stay effective.

Future Applications and Industry Impact

The technology’s potential extends beyond tire changes. Researchers are adapting similar platforms for brake inspections, suspension adjustments, and even EV battery swaps. Partnerships between automakers and robotics firms hint at a future where dealerships and service chains adopt fully automated garages.

In the consumer sector, startups are prototyping portable tire-changing robots that could be deployed for roadside assistance. Imagine a compact machine stored in a car’s trunk, capable of replacing a flat tire autonomously—a game-changer for drivers stranded in remote areas.

Robotic tire replacement technology represents a fusion of mechanical ingenuity and digital intelligence. While challenges like cost and adaptability persist, ongoing advancements in AI and material science are accelerating its adoption. As these systems become more accessible, they promise to enhance safety, efficiency, and convenience across the automotive ecosystem—ushering in a new era where robots and humans collaborate to keep the world moving.