In the rapidly evolving landscape of industrial automation, Supcon Technology has emerged as a trailblazer with its cutting-edge robotic solutions. By integrating advanced control systems, artificial intelligence, and modular design principles, the company’s robotics portfolio is redefining efficiency, precision, and adaptability across manufacturing, logistics, and energy sectors. This article explores the core features of Supcon’s robotic products and their transformative impact on modern industries.

The Evolution of Supcon’s Robotics Ecosystem

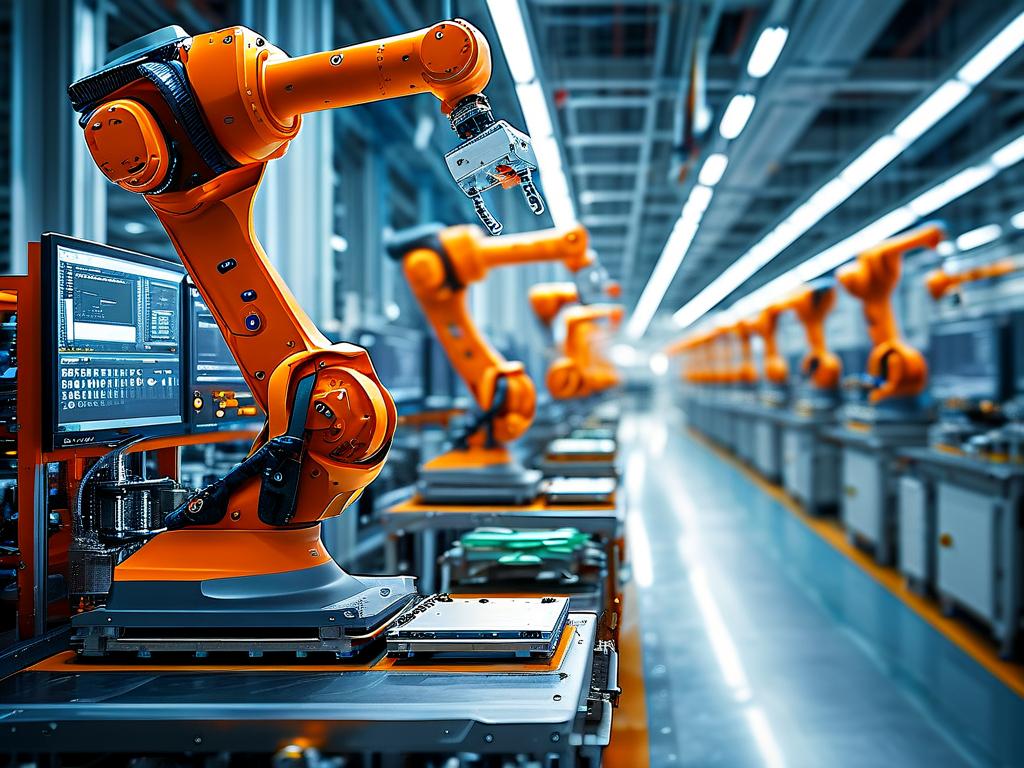

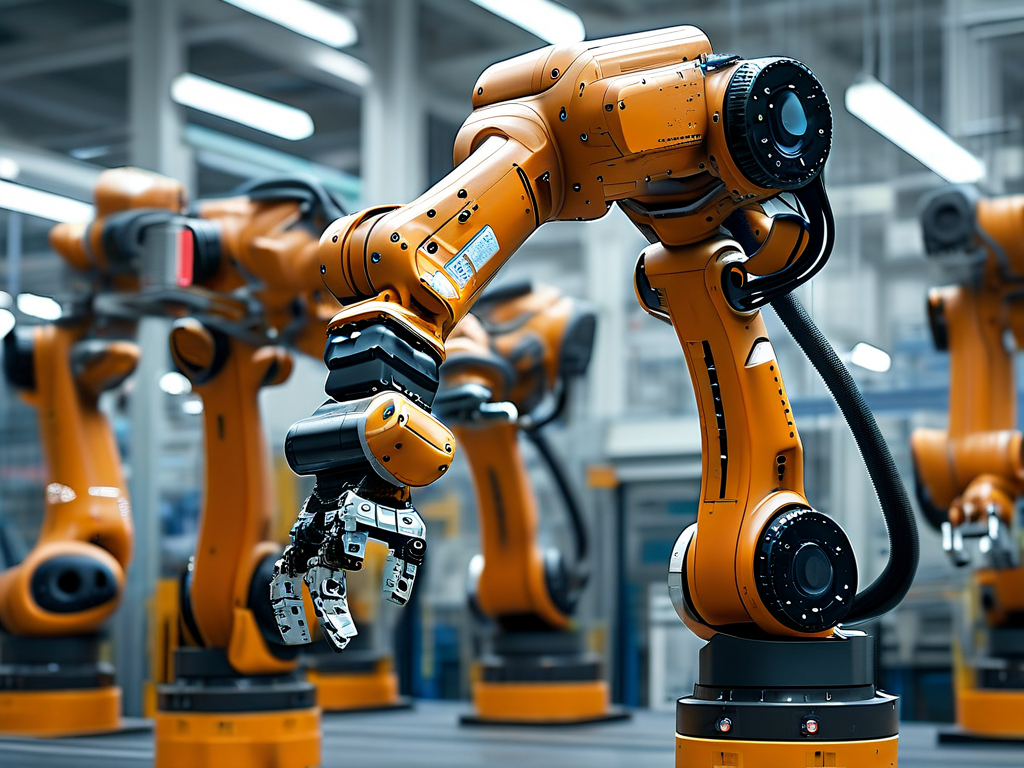

Supcon’s journey in robotics began with a focus on addressing gaps in traditional automation. Early industrial robots often struggled with dynamic environments, requiring manual recalibration for minor workflow changes. To overcome this, Supcon engineers developed proprietary adaptive control algorithms that enable real-time adjustments based on sensory feedback. For instance, their SCARA (Selective Compliance Articulated Robot Arm) series incorporates vision-guided positioning, allowing robots to handle irregularly shaped objects without pre-programmed coordinates. This flexibility has proven invaluable in electronics assembly lines, where component variations are frequent.

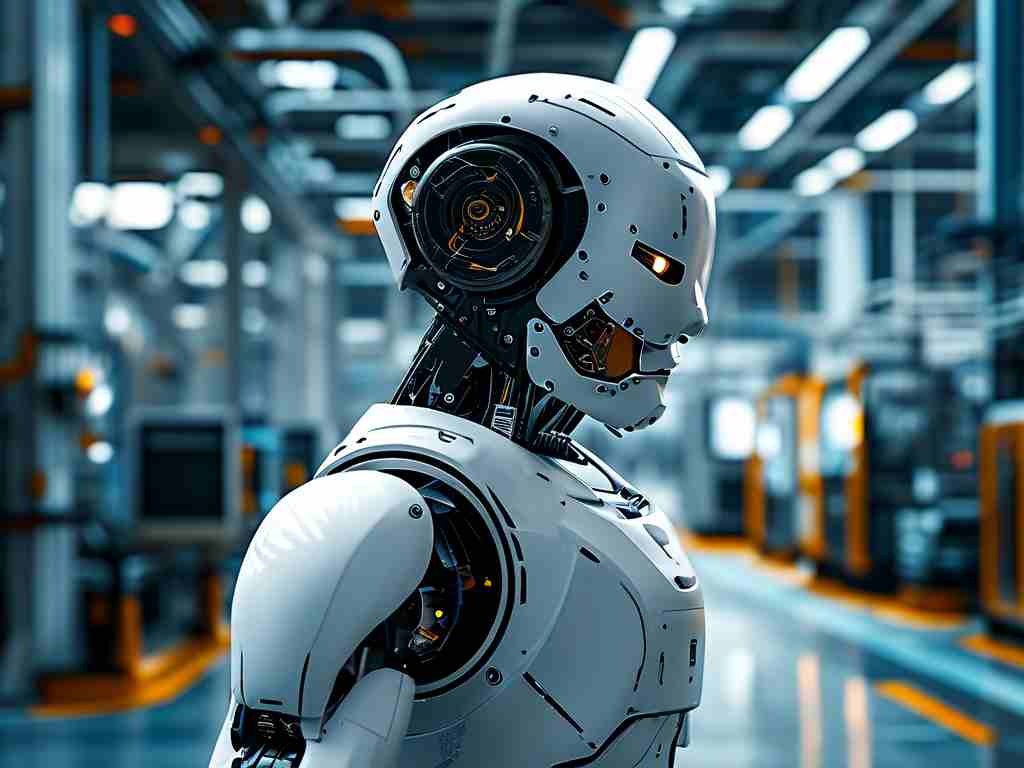

Another standout innovation is Supcon’s collaborative robot (cobot) lineup. Unlike conventional robots confined to safety cages, these cobots use torque sensors and machine learning to detect human presence, reducing collision risks while maintaining operational speed. A case study from a Zhejiang automotive parts factory revealed a 34% productivity boost after deploying Supcon’s cobots for precision welding tasks alongside human technicians.

Core Technologies Driving Performance

At the heart of Supcon’s robotic systems lies its proprietary Smart Control Platform (SCP). This unified architecture synchronizes motion control, data analytics, and edge computing capabilities. By processing data locally rather than relying on cloud servers, SCP minimizes latency—a critical advantage for applications like semiconductor manufacturing, where nanosecond-level timing is essential.

The company’s emphasis on interoperability further distinguishes its offerings. Supcon robots seamlessly integrate with legacy machinery through standardized communication protocols like OPC UA and Modbus. A dairy producer in Inner Mongolia successfully connected Supcon’s packaging robots to 20-year-old filling machines, achieving end-to-end automation without costly equipment replacements.

Energy efficiency is another hallmark. Supcon’s latest AGV (Automated Guided Vehicle) models utilize regenerative braking and route optimization algorithms, cutting power consumption by 22% compared to industry averages. These advancements align with global sustainability goals while reducing operational costs.

Industry-Specific Applications

Supcon tailors its robotic solutions to sector-specific challenges. In oil and gas, explosion-proof inspection robots equipped with thermal cameras and gas sensors perform hazardous pipeline monitoring—tasks previously requiring human intervention. Meanwhile, in pharmaceuticals, sterile-environment robots execute vial handling with ISO Class 5 cleanliness compliance, minimizing contamination risks.

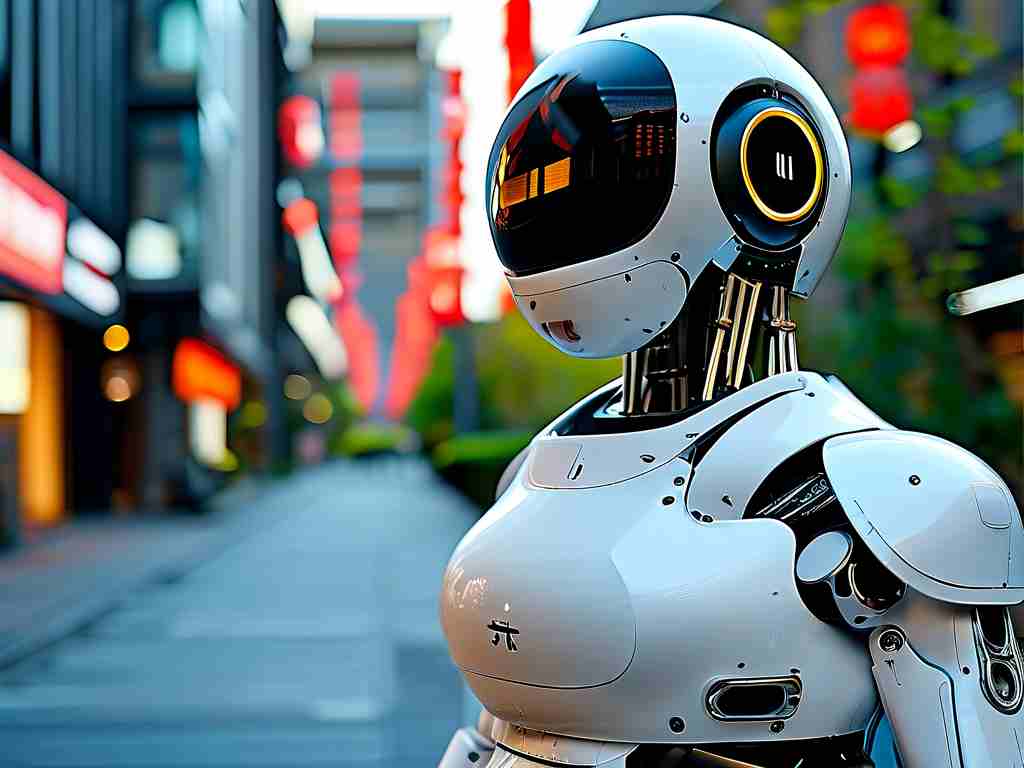

The logistics sector has particularly benefited from Supcon’s mobile sorting robots. Using SLAM (Simultaneous Localization and Mapping) technology, these units navigate warehouse floors autonomously, adapting to layout changes within hours. During a 2023 trial at a Shanghai e-commerce hub, Supcon’s system achieved 99.2% sorting accuracy while processing 8,000 parcels hourly.

Future Horizons and Market Outlook

Looking ahead, Supcon is investing in swarm robotics and quantum computing integration. Early prototypes demonstrate coordinated multi-robot operations for large-scale agricultural planting, where fleets of drones and ground robots collaboratively manage crop monitoring and fertilization.

As Industry 4.0 accelerates, Supcon’s fusion of robust hardware and intelligent software positions it as a key enabler of the “lights-out factory” paradigm. With a 19% year-on-year growth in robotics revenue reported in Q1 2024, the company continues to expand its global footprint, recently securing partnerships with European automotive giants and Southeast Asian smart city projects.

In , Supcon Technology’s robotic innovations exemplify how smart control systems can bridge the gap between theoretical automation potential and real-world industrial demands. By prioritizing adaptability, energy sustainability, and cross-industry scalability, the company isn’t just selling robots—it’s engineering the backbone of tomorrow’s autonomous enterprises.