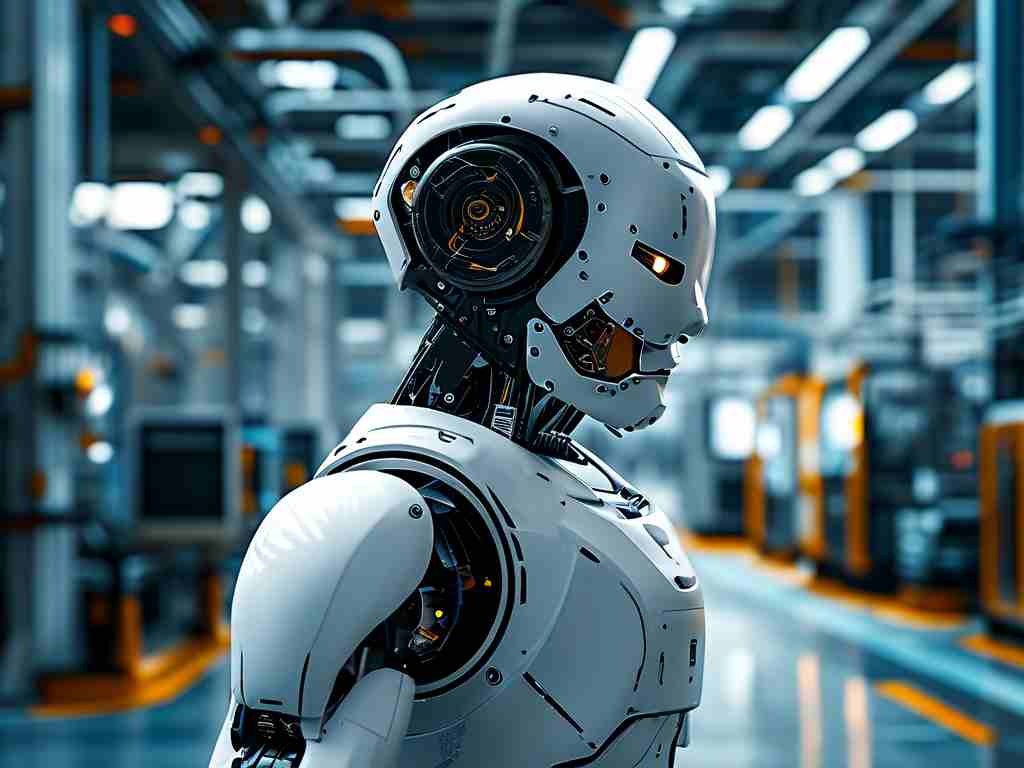

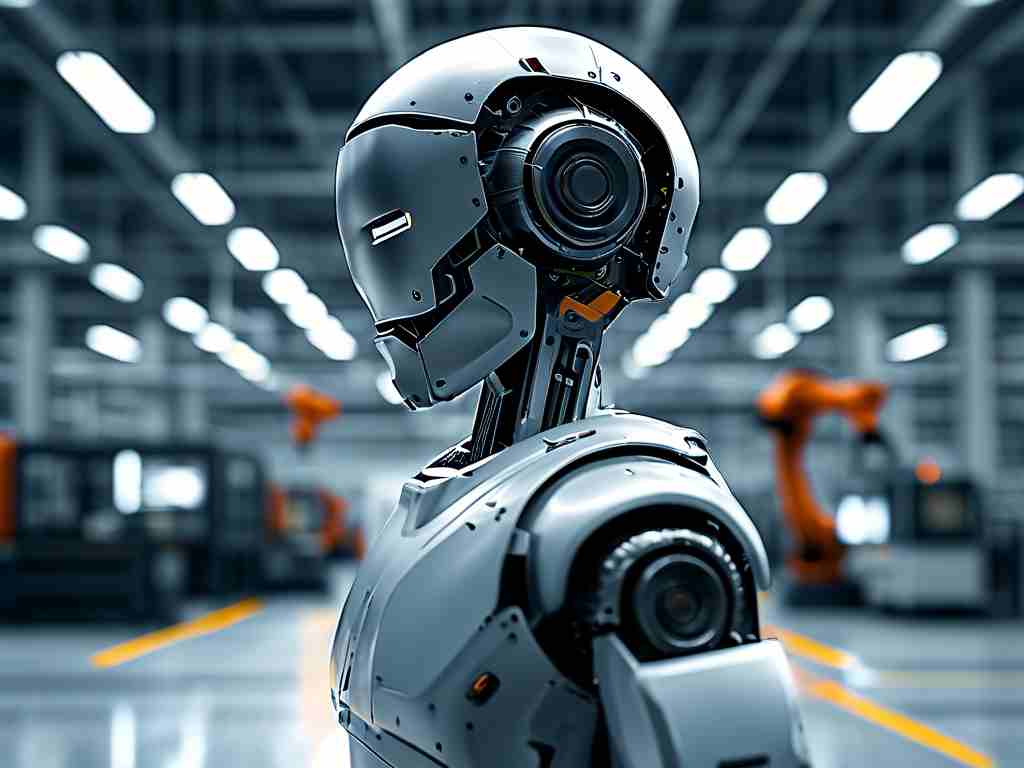

As the global manufacturing sector undergoes a digital metamorphosis, Inovance Technology has emerged as a trailblazer in intelligent robotics, redefining industrial workflows through cutting-edge AI integration. The company’s latest generation of smart robots combines adaptive machine learning, real-time data analytics, and precision engineering, offering solutions that transcend traditional automation boundaries.

The Architecture of Innovation

At the core of Inovance’s robotic systems lies a proprietary neural network framework dubbed SynapticCore. Unlike conventional programmable logic controllers, this architecture enables robots to dynamically adjust motion trajectories and operational parameters based on environmental feedback. For instance, in automotive welding applications, sensors detect micron-level material variations, while onboard algorithms recalculate welding paths within 50 milliseconds—a feat unachievable by human operators.

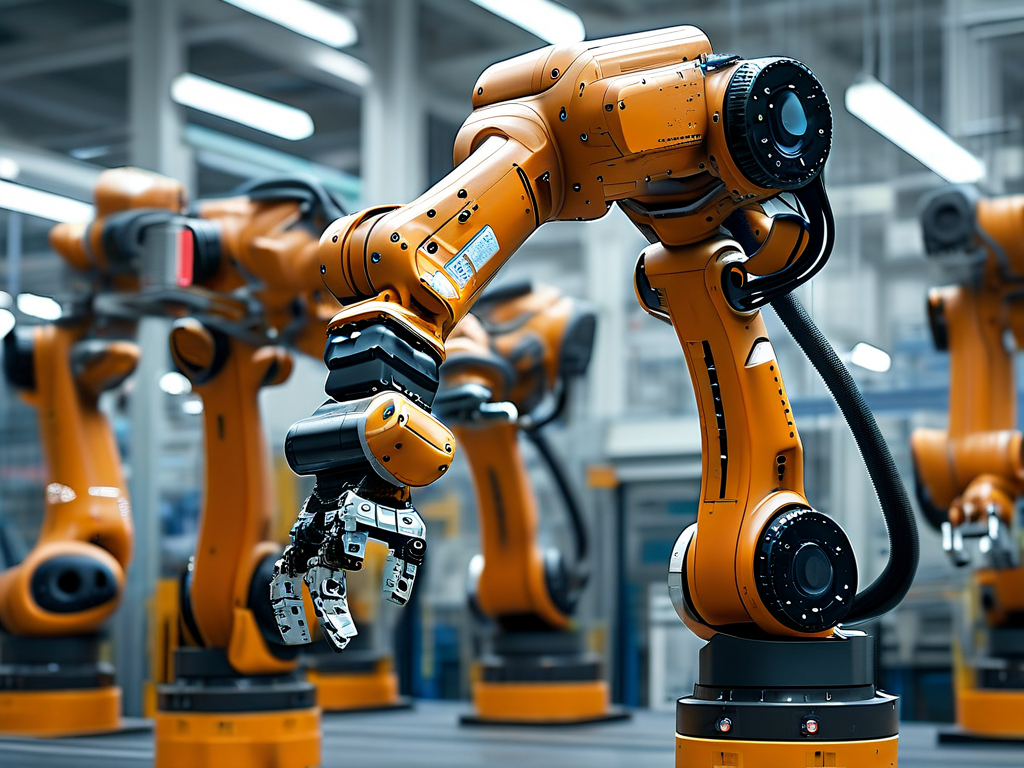

Cross-Industry Applications

- Electronics Manufacturing: Deployed in SMT (surface-mount technology) lines, Inovance’s SCARA robots achieve component placement accuracy of ±0.01mm, coupled with self-diagnostic routines that predict mechanical wear 400 hours before failure.

- Pharmaceuticals: Sterile environment models utilize UV-C sterilization modules integrated with robotic arms, maintaining ISO Class 5 cleanliness while handling vial packaging at 200 units/minute.

- Agriculture: The AgriBot Pro series demonstrates machine vision-powered fruit picking, reducing harvest damage rates from 15% to 2.3% through tactile force feedback systems.

Human-Robot Synergy

Contrary to displacement fears, Inovance’s solutions emphasize collaborative robotics (cobots). The SafeCollab series features capacitive skin technology that halts operation upon detecting human proximity within 15cm. In a Guangdong-based appliance factory, these cobots increased production line efficiency by 37% while reducing workplace injuries by 82% year-over-year.

Sustainability Edge

Energy optimization algorithms embedded in Inovance’s drives cut power consumption by 23-41% across operational modes. During peak shaving scenarios, robots can enter ultra-low-power states (0.4W standby) without losing positional memory—a critical feature for regions with unstable grid infrastructure.

Developer Ecosystem

The company’s OpenRobot platform provides APIs for customizing robotic behaviors. A notable case involves a third-party developer creating a palletizing algorithm that reduced logistic center sorting errors by 91% using the following code snippet:

def dynamic_palletize(obj_list):

from inovance_ml import density_optimizer

return density_optimizer(obj_list,

max_height=1.8m,

weight_dist='gaussian')

Market Traction

With installations across 37 countries, Inovance’s robotics division reported 154% YoY growth in Q2 2024, particularly strong in Southeast Asian markets. The MX600 model alone accounts for 28% of China’s industrial robot imports substitution, according to CAIC (China Automation Industry Council).

Ethical AI Framework

Addressing algorithmic bias concerns, Inovance implemented a three-tiered validation system:

- Hardware-level checksum verification for decision trees

- Cloud-based anomaly detection during firmware updates

- Monthly ethics audits by external AI governance consortiums

As Industry 4.0 accelerates, Inovance’s intelligent robotics solutions are not merely automating tasks—they’re crafting a blueprint for responsive, responsible, and resilient manufacturing ecosystems. The convergence of their modular designs with 5G-enabled edge computing promises to unlock unprecedented flexibility, potentially reducing factory retooling timelines from weeks to hours in the coming decade.