In the heart of China’s bustling industrial landscape, Shanghai has emerged as a hub for cutting-edge robotics technology. Among the key players shaping this sector is Yamaha Robotics, a branch of the globally renowned Yamaha Motor Group. Specializing in automation solutions, Shanghai Yamaha Robotics has become synonymous with precision, efficiency, and innovation, catering to industries ranging from automotive manufacturing to electronics assembly. This article explores the company’s technological advancements, its impact on local and global markets, and the future trends it is helping to define.

Technological Breakthroughs in Automation

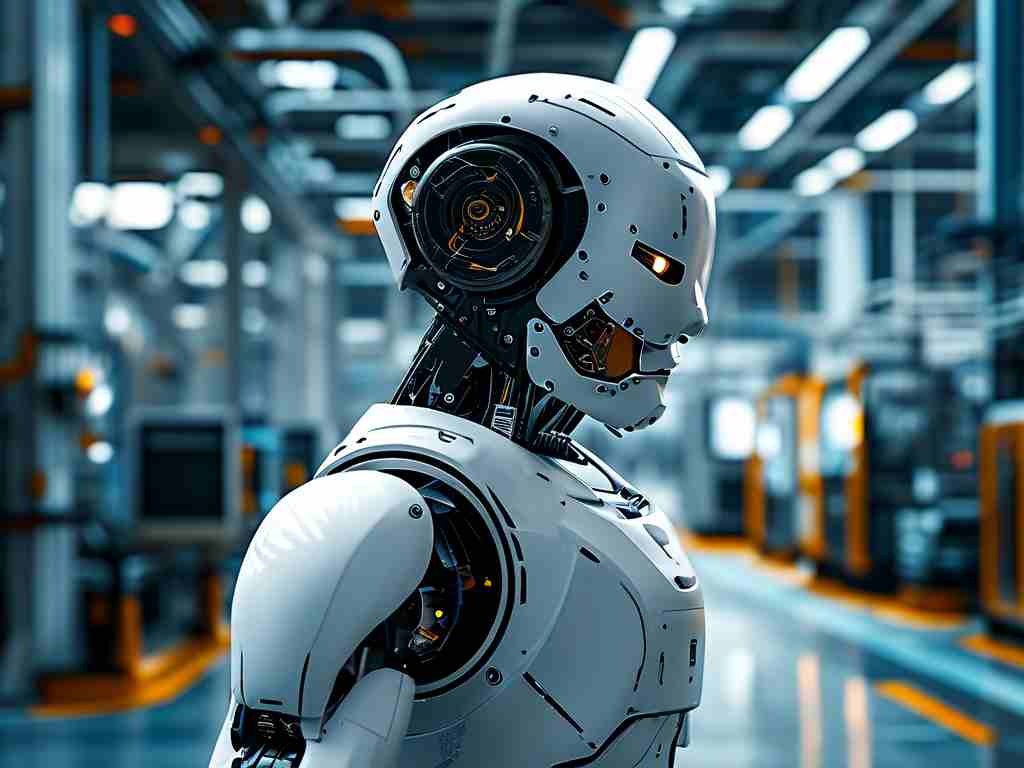

Shanghai Yamaha Robotics has pioneered several advancements in robotic systems, particularly in modular design and adaptive control algorithms. Unlike traditional robots limited to repetitive tasks, Yamaha’s latest models integrate AI-driven vision systems capable of real-time object recognition and decision-making. For example, their YKX series of collaborative robots (cobots) employs machine learning to optimize workflows in dynamic environments, such as sorting mixed-material components on production lines.

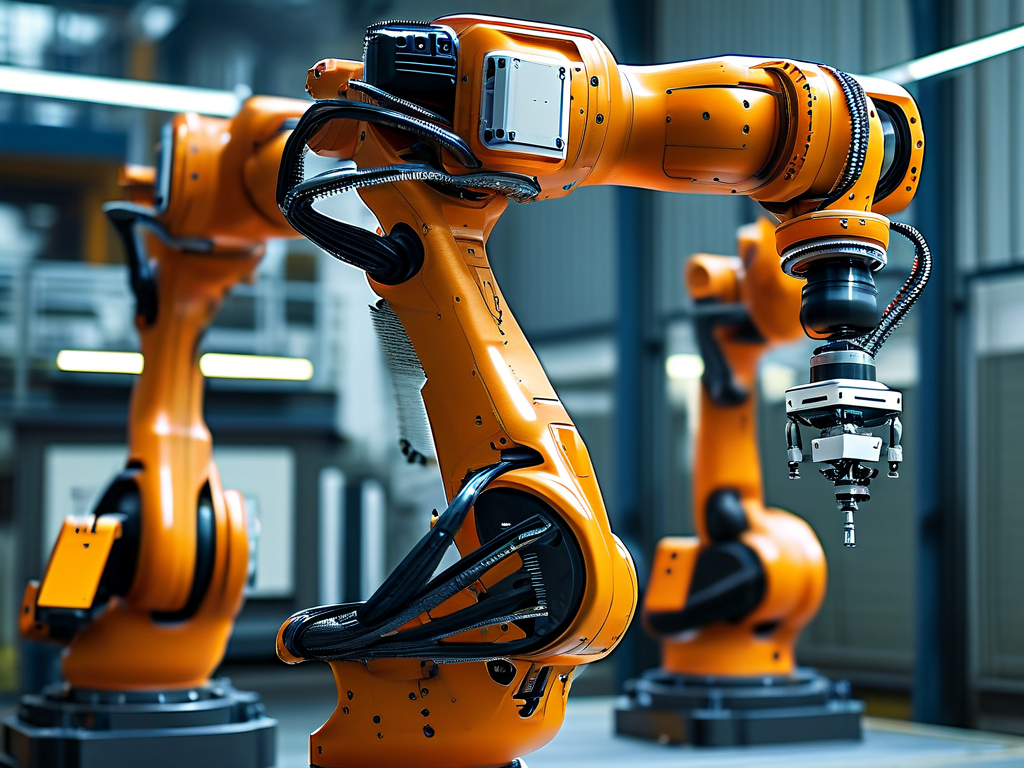

Another standout innovation is the company’s emphasis on energy efficiency. By incorporating regenerative braking systems and low-power actuators, Yamaha’s robots reduce energy consumption by up to 30% compared to conventional models. This aligns with China’s national goals for sustainable manufacturing, positioning the company as a leader in eco-friendly automation.

Applications Across Industries

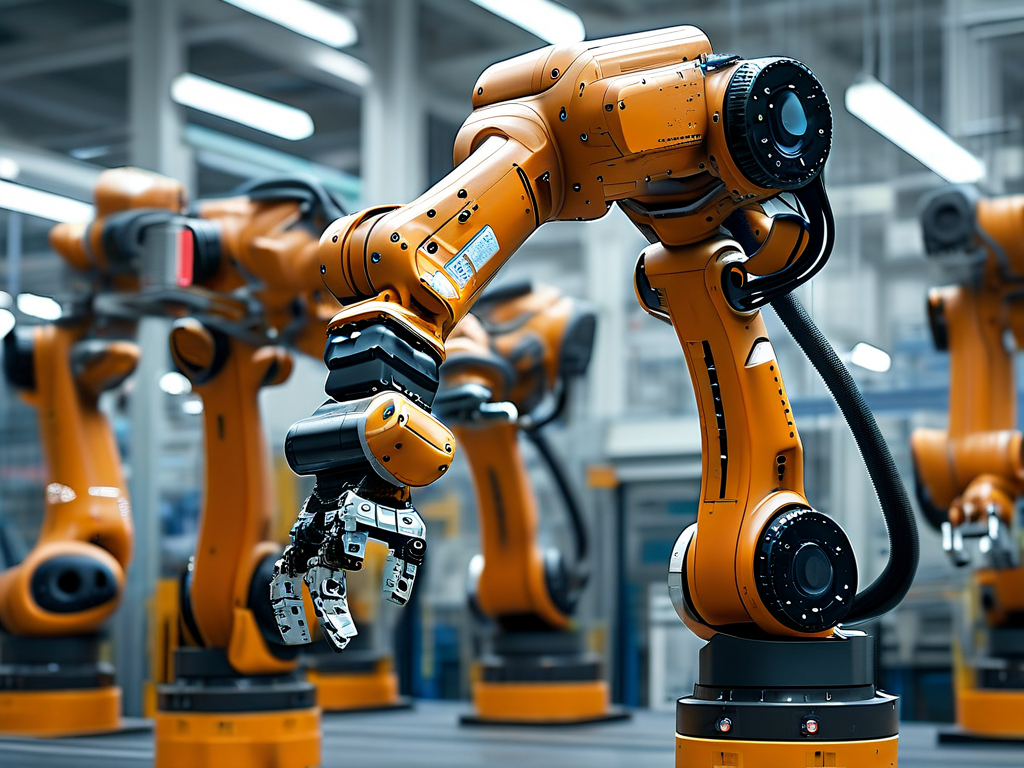

The versatility of Yamaha’s robotic solutions has enabled their adoption across diverse sectors. In automotive manufacturing, Shanghai-based factories utilize Yamaha’s high-speed SCARA robots for precision welding and assembly. These robots operate with micron-level accuracy, critical for producing electric vehicle (EV) battery modules. Meanwhile, in the electronics sector, companies like Huawei and Foxconn leverage Yamaha’s dual-arm robots for delicate tasks such as circuit board soldering and microcomponent placement.

Beyond heavy industry, Yamaha’s technology is making waves in healthcare and logistics. During the COVID-19 pandemic, the company adapted its robotic arms for medical supply packaging and disinfection tasks. More recently, their autonomous mobile robots (AMRs) have been deployed in Shanghai’s smart warehouses, navigating complex layouts using LiDAR and 3D mapping.

Global Competitiveness and Local Synergy

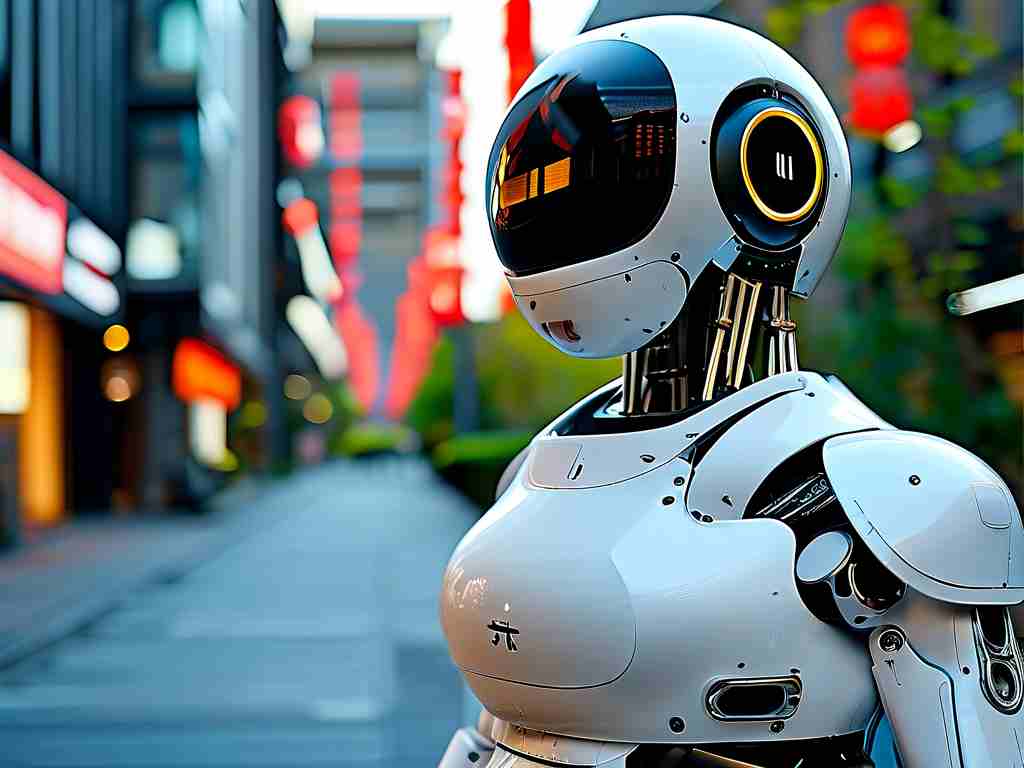

While Yamaha Robotics operates globally, its Shanghai division plays a strategic role in tailoring solutions for Asian markets. The facility collaborates closely with regional manufacturers to address unique challenges, such as high-mix, low-volume production demands. By offering customizable software interfaces and rapid prototyping services, the company has gained a competitive edge over European and American rivals.

Local partnerships further amplify this success. Shanghai Yamaha Robotics works with universities like Tongji and Fudan to nurture engineering talent, ensuring a pipeline of skilled professionals familiar with their systems. Additionally, government initiatives like the “Made in China 2025” plan provide subsidies for manufacturers adopting advanced automation, indirectly boosting Yamaha’s market penetration.

Future Trends and Challenges

Looking ahead, Shanghai Yamaha Robotics is investing heavily in two areas: human-robot collaboration and 5G-enabled automation. Their next-generation cobots will feature enhanced safety protocols, allowing seamless interaction with human workers in shared spaces. Trials are underway in Shanghai’s smart factories, where these cobots assist in quality inspection and material handling.

The integration of 5G technology promises to revolutionize remote robot control and data analytics. Yamaha’s R&D team is developing cloud-based platforms that enable real-time monitoring of robotic fleets across multiple facilities. This could reduce downtime by predicting maintenance needs and optimizing production schedules.

However, challenges persist. Supply chain disruptions, particularly semiconductor shortages, have delayed product launches. Moreover, rising labor costs in China are pushing smaller manufacturers to seek cheaper alternatives, prompting Yamaha to introduce cost-effective entry-level models without compromising performance.

Shanghai Yamaha Robotics exemplifies how innovation and adaptability drive industrial progress. By merging advanced AI, sustainable engineering, and localized strategies, the company not only meets current market demands but also shapes the future of automation. As industries worldwide grapple with digital transformation, Yamaha’s solutions offer a blueprint for balancing efficiency, flexibility, and environmental responsibility. With its finger on the pulse of technological trends, the Shanghai division is poised to remain a cornerstone of global robotics advancement.