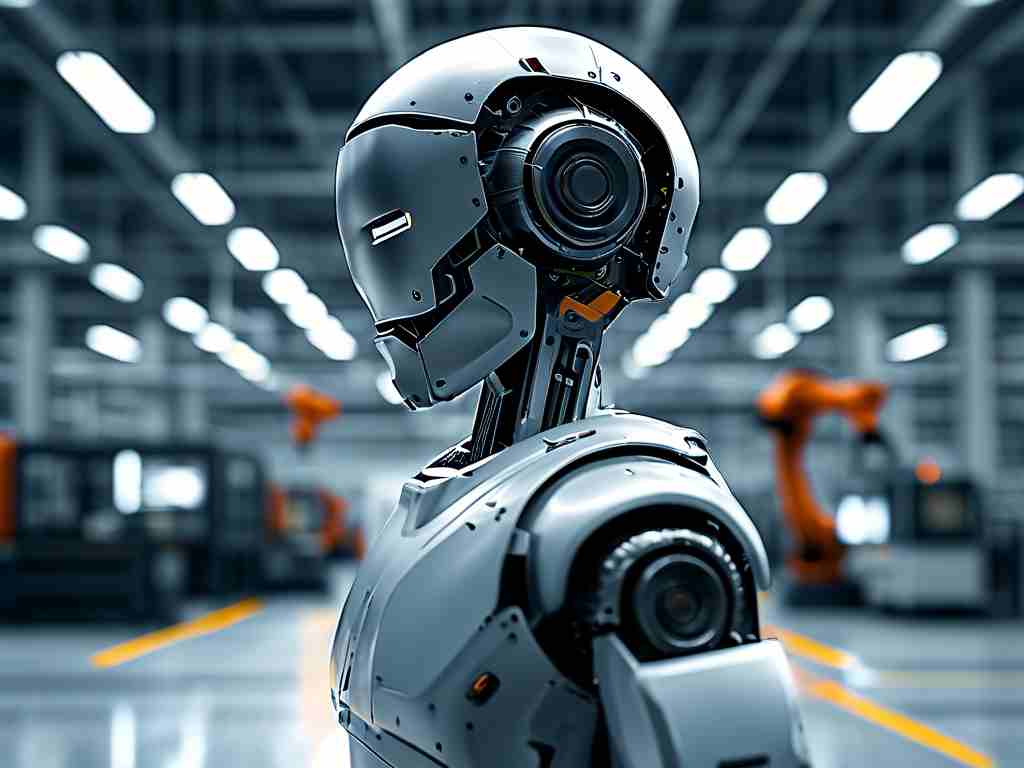

In modern manufacturing and construction industries, robotic drilling technology has emerged as a transformative force, redefining standards for accuracy, speed, and operational safety. Unlike traditional manual or semi-automated drilling methods, robotic systems integrate advanced sensors, machine learning algorithms, and real-time data analysis to deliver unparalleled performance. This article explores the multifaceted advantages of this innovation and its implications for industries ranging from aerospace to renewable energy.

One of the most significant benefits of robotic drilling lies in its precision engineering capabilities. Human-operated drills often face challenges such as tool slippage, inconsistent pressure application, or alignment errors—issues that become critical in high-stakes environments like aircraft manufacturing or microelectronics. Robotic systems, however, utilize laser-guided positioning and force feedback mechanisms to maintain sub-millimeter accuracy. For instance, in aerospace applications, robots drill thousands of holes in composite materials with tolerances tighter than 0.1 mm, ensuring structural integrity while reducing material waste.

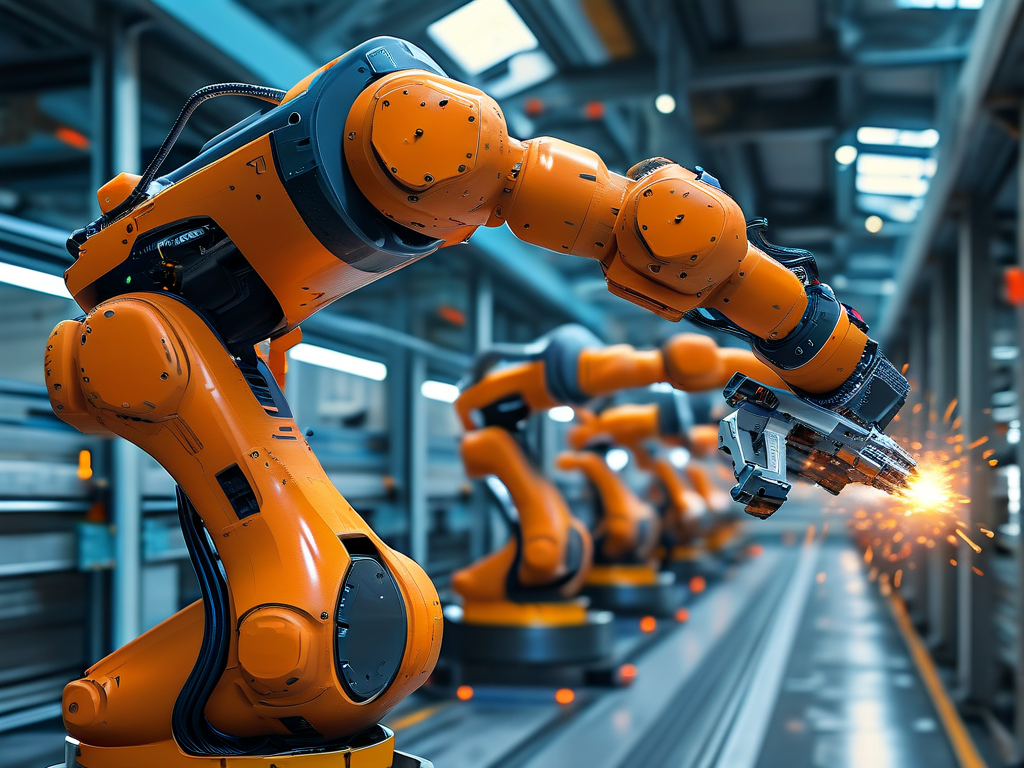

Enhanced productivity is another cornerstone of robotic drilling technology. These systems operate continuously without fatigue, achieving cycle times up to 50% faster than human workers. A case study from the automotive sector revealed that a single robotic drill unit could complete 120 precision holes per hour on engine blocks—a task requiring three shifts with manual labor. Moreover, robots seamlessly integrate with production lines, enabling 24/7 operations and minimizing downtime during tool changes through automated bit-swapping mechanisms.

Safety improvements represent a less visible but equally vital advantage. Drilling tasks often expose workers to hazards like flying debris, repetitive motion injuries, or exposure to hazardous materials. By delegating these tasks to robots, companies report a 70–80% reduction in workplace accidents related to drilling operations. Advanced models even incorporate collision detection systems that halt operations if unexpected obstacles appear, protecting both machinery and personnel.

The adaptability of robotic drilling systems sets them apart in dynamic industrial landscapes. Modern units feature modular designs that allow quick reconfiguration for different materials or hole patterns. A notable example comes from the wind energy sector, where robots adjust drilling parameters in real time to handle variations in turbine blade composites. This flexibility extends to software: cloud-connected robots receive firmware updates to support new materials or comply with evolving industry standards.

Cost efficiency, while sometimes overshadowed by technical benefits, remains a key driver for adoption. Although initial investments in robotic systems can be substantial, long-term savings from reduced labor costs, lower error rates, and minimized material waste create compelling ROI. Data from a shipbuilding consortium showed a 34% reduction in per-unit drilling costs after implementing robotic solutions, primarily due to eliminated rework from human errors.

Looking ahead, the integration of artificial intelligence promises to amplify these advantages. AI-powered predictive maintenance algorithms now enable robots to anticipate drill bit wear or motor failures before they occur, further optimizing uptime. Meanwhile, computer vision advancements allow robots to identify and adapt to surface irregularities in real time—a capability being tested in offshore oil rig maintenance.

Despite these advancements, challenges persist. Smaller manufacturers often face barriers related to upfront costs and technical expertise required for system programming. However, the rise of Robotics-as-a-Service (RaaS) models and user-friendly interfaces is gradually democratizing access. Collaborative robots (cobots) designed to work alongside humans are also gaining traction, blending robotic precision with human problem-solving skills for complex tasks.

In , robotic drilling technology is not merely an incremental improvement but a paradigm shift in industrial processes. By combining surgical precision, relentless productivity, and intelligent adaptability, these systems are setting new benchmarks across sectors. As the technology matures and becomes more accessible, its role in shaping efficient, safe, and sustainable industries will only expand.