The rapid evolution of automation technologies has positioned industrial robotics as a cornerstone of modern manufacturing, logistics, and even healthcare. Learning industrial robot programming is no longer a niche skill but a critical competency for engineers, technicians, and innovators aiming to thrive in the Fourth Industrial Revolution. This article explores the significance of mastering industrial robot programming, its applications, and actionable steps to build expertise in this transformative field.

The Rising Demand for Industrial Robot Programming Skills

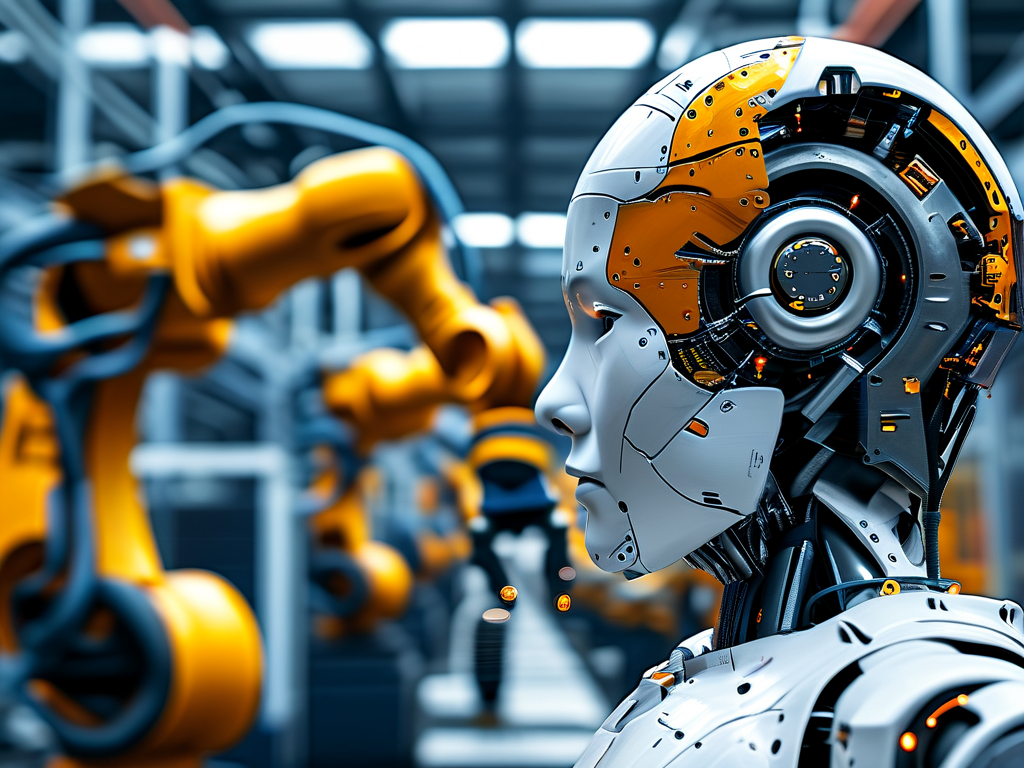

Industrial robots are revolutionizing industries by performing repetitive, precise, and hazardous tasks with unmatched efficiency. From automotive assembly lines to pharmaceutical packaging, robots now handle tasks that were once labor-intensive or unsafe for humans. According to the International Federation of Robotics (IFR), over 3 million industrial robots are operational worldwide, with installations growing by 12% annually. This surge has created a global demand for professionals skilled in programming, maintaining, and optimizing these machines.

Companies seek individuals who can bridge the gap between mechanical systems and digital control. Proficiency in robot programming ensures seamless integration of robots into production workflows, reducing downtime and maximizing ROI. As industries adopt collaborative robots (cobots) and AI-driven automation, the ability to program and adapt robotic systems becomes even more valuable.

Core Concepts in Industrial Robot Programming

Industrial robot programming involves writing code or configuring software to dictate a robot’s movements, tasks, and interactions. Key concepts include:

- Kinematics and Motion Planning: Understanding how robots move in 3D space, including forward and inverse kinematics, is fundamental. Programmers must define trajectories, avoid collisions, and optimize paths for speed and precision.

- Programming Languages: While brands like KUKA (KRL), ABB (RAPID), and Fanuc (TP) use proprietary languages, universal frameworks like ROS (Robot Operating System) and Python-based tools are gaining traction.

- Sensor Integration: Robots rely on sensors (vision systems, force-torque sensors) to interact with their environment. Programming these interactions requires knowledge of real-time data processing and feedback loops.

- Safety Protocols: Ensuring compliance with safety standards (e.g., ISO 10218) is critical, especially when programming cobots designed to work alongside humans.

Steps to Learn Industrial Robot Programming

- Build a Foundation in Robotics Theory: Start with courses or textbooks covering robotics fundamentals—mechanics, electronics, and control systems. Platforms like Coursera and edX offer specialized programs from institutions like MIT and ETH Zurich.

- Hands-On Practice with Simulation Tools: Software like MATLAB, Gazebo, or brand-specific simulators (e.g., KUKA Sim Pro) allows learners to program virtual robots without physical hardware.

- Work with Real Hardware: Access to industrial robots is ideal, but hobbyist kits (e.g., Universal Robots’ UR3e or Arduino-based arms) provide affordable entry points. Many technical schools and maker spaces also offer lab access.

- Master Industry-Standard Software: Familiarize yourself with popular platforms like RobotStudio (ABB), RoboDK, or ROS. Certifications from robot manufacturers can enhance employability.

- Stay Updated on Trends: Explore emerging areas like AI-driven vision systems, digital twins, and IoT-enabled robotics.

Applications Across Industries

Industrial robot programming skills unlock opportunities in diverse sectors:

- Manufacturing: Automating welding, painting, and assembly processes.

- Logistics: Programming autonomous mobile robots (AMRs) for warehouse management.

- Healthcare: Developing surgical robots or rehabilitation assistants.

- Agriculture: Deploying robots for planting, harvesting, and monitoring crops.

Challenges and Future Outlook

While learning robot programming is rewarding, challenges include the high cost of equipment and the complexity of integrating AI. However, open-source communities and cloud-based robotics platforms are democratizing access. The future will see robots becoming more adaptive and intuitive, with programming shifting toward no-code interfaces and machine learning.

Mastering industrial robot programming is not just about writing code—it’s about shaping the future of automation. As industries worldwide embrace smart manufacturing, professionals with these skills will lead innovation, drive efficiency, and solve complex challenges. Whether you’re an engineer, student, or career changer, investing in robotics education today ensures a competitive edge in tomorrow’s automated world.