The evolution of industrial robotics has redefined manufacturing processes, blending precision, adaptability, and intelligence into production lines. These machines are no longer confined to repetitive tasks but have evolved into sophisticated systems capable of complex operations. Understanding their core technical features provides insights into how they drive efficiency and innovation across industries.

Precision and Repeatability

One of the defining characteristics of industrial robots is their unparalleled precision. Equipped with advanced servo motors and high-resolution encoders, these systems achieve micrometer-level accuracy, essential for tasks like semiconductor assembly or medical device manufacturing. Repeatability ensures that a robot can perform the same action thousands of times without deviation, a critical factor in automotive welding or electronics packaging. For instance, in automotive paint shops, robotic arms apply coatings with consistent thickness, minimizing material waste and ensuring uniform quality.

Adaptive Flexibility

Modern industrial robots are designed for modularity, allowing rapid reconfiguration to accommodate diverse workflows. Collaborative robots (cobots), for example, feature lightweight structures and intuitive programming interfaces, enabling seamless integration into small-batch production environments. This flexibility extends to end-effector compatibility—tools like grippers, sensors, or welding torches can be swapped to suit specific tasks. A notable application is in food processing, where a single robotic system might handle sorting, packaging, and quality inspection by simply altering its attachments and software parameters.

Intelligent Sensing and Decision-Making

The integration of AI and machine learning has transformed robots from passive executors to active decision-makers. Vision systems powered by 3D cameras and LiDAR enable real-time object recognition and spatial mapping, allowing robots to adjust their paths dynamically. In logistics warehouses, autonomous mobile robots (AMRs) navigate complex layouts while avoiding obstacles, optimizing inventory management. Additionally, force-torque sensors let robots perform delicate operations, such as inserting fragile components into circuit boards, by adapting pressure on the fly.

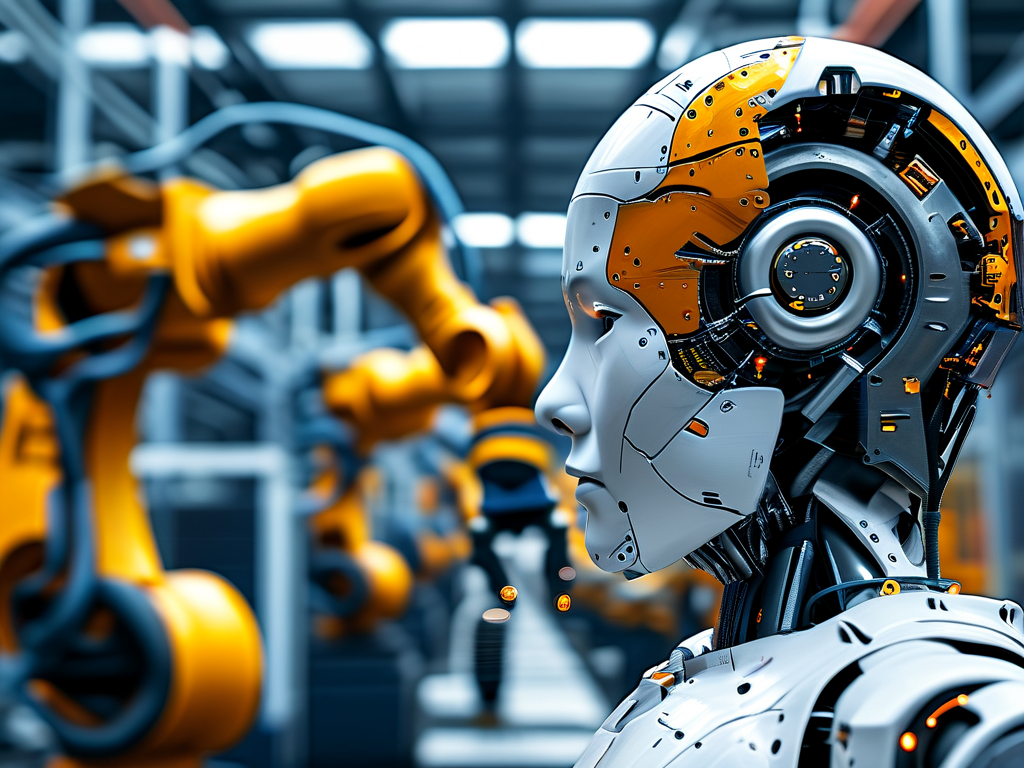

Interconnectivity and Industry 4.0 Integration

Industrial robots now function as nodes within interconnected smart factories. Through protocols like OPC UA or MQTT, they exchange data with PLCs, ERP systems, and cloud platforms. This connectivity enables predictive maintenance—analyzing motor vibration patterns or temperature trends to preempt failures. In aerospace manufacturing, robots synchronize with digital twins, simulating assembly processes before physical execution to reduce downtime. Such integration aligns with the broader shift toward data-driven, agile production models.

Safety and Human Collaboration

Safety mechanisms have advanced significantly, particularly for cobots operating alongside human workers. Technologies like capacitive skin sensing and laser scanners detect proximity, triggering slowdowns or halts to prevent accidents. For instance, in electronics assembly lines, cobots handle soldering tasks while humans oversee quality checks, with safety systems ensuring smooth coexistence. Furthermore, ergonomic designs reduce physical strain during programming or maintenance, broadening their usability across workforce skill levels.

Energy Efficiency and Sustainability

Contemporary robotic systems prioritize energy conservation through regenerative braking, idle mode activation, and optimized motion planning. Reduced power consumption not only lowers operational costs but also supports sustainable manufacturing goals. In metal fabrication, robots calculate the shortest welding paths to minimize energy use, while recycling scrap material autonomously. Such features align with global initiatives to reduce industrial carbon footprints.

In , the technical features of industrial robots—precision, adaptability, intelligence, connectivity, safety, and sustainability—collectively underpin their transformative role in modern manufacturing. As AI, edge computing, and material science advance, these systems will continue to evolve, unlocking new possibilities for innovation across sectors. Manufacturers investing in these technologies today position themselves at the forefront of the fourth industrial revolution.