Industrial robots have become indispensable in modern manufacturing, driven by their evolving technical capabilities that enhance precision, efficiency, and adaptability. These machines are no longer confined to repetitive tasks but now integrate advanced technologies to meet the demands of smart factories. This article explores the defining technical features of industrial robots and their transformative impact on production processes.

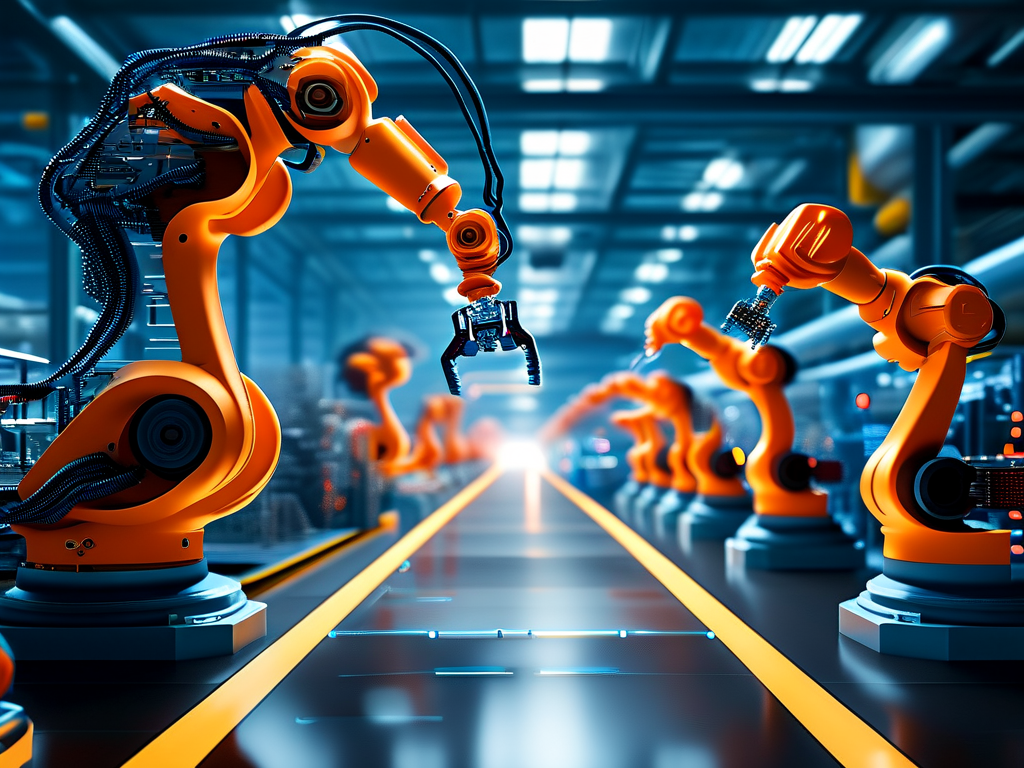

One of the most critical technical features of industrial robots is high precision and repeatability. Equipped with servo motors, harmonic drives, and advanced sensors, these robots achieve micron-level accuracy in tasks such as welding, assembly, and material handling. For instance, in automotive manufacturing, robotic arms consistently position components within 0.1mm tolerances, ensuring product uniformity. This precision minimizes human error and reduces material waste, directly contributing to cost savings.

Adaptive control systems further distinguish modern industrial robots. Unlike traditional fixed automation, contemporary robots leverage machine learning algorithms and real-time feedback mechanisms to adjust operations dynamically. For example, vision-guided robots can identify irregularly placed parts on a conveyor belt and recalibrate their movements instantaneously. This flexibility is vital in industries like electronics, where product designs change rapidly.

Another hallmark is multi-axis mobility. Most industrial robots now feature six or seven degrees of freedom, mimicking the flexibility of a human arm. This allows them to perform complex maneuvers in confined spaces—such as threading wires in aerospace assemblies—or handle irregularly shaped objects. Collaborative robots (cobots) take this further by integrating force-torque sensors to operate safely alongside humans, expanding their applications in small-batch production.

Interconnectivity via Industry 4.0 frameworks has also redefined robotic systems. Industrial robots are increasingly embedded with IoT-enabled controllers that communicate with other machines, enterprise software, and cloud platforms. A robotic arm in a smart factory might share performance data with a predictive maintenance system, enabling preemptive repairs before a breakdown occurs. This connectivity supports just-in-time manufacturing and reduces downtime.

Energy efficiency has emerged as a key focus in robot design. Regenerative braking systems, for instance, capture kinetic energy during deceleration and reuse it for subsequent operations. Companies like ABB report up to 20% energy savings in their latest models. Such innovations align with global sustainability goals while lowering operational costs.

However, challenges persist. The complexity of programming advanced robots requires specialized skills, prompting the development of intuitive programming interfaces. Offline simulation software now allows engineers to design workflows in virtual environments before deployment. Universal Robots’ teach pendant, featuring drag-and-drop command blocks, exemplifies this trend toward user-friendly controls.

Safety remains paramount. Modern robots incorporate redundant safety circuits, emergency stop protocols, and 3D zone monitoring. Laser scanners can create dynamic safety fields around robots, instantly halting operations if a human enters a restricted area. These features comply with ISO 10218 standards while maintaining productivity.

Looking ahead, the integration of artificial intelligence is pushing boundaries. AI-powered robots can analyze historical data to optimize motion paths or predict tool wear. In a recent case study, Fanuc’s AI-driven robots reduced cycle times by 15% in a machining cell through self-optimized tool trajectories.

In , the technical evolution of industrial robots—spanning precision mechanics, adaptive intelligence, and seamless connectivity—is revolutionizing manufacturing. As these systems grow smarter and more collaborative, they will continue to unlock new possibilities across industries, from pharmaceuticals to renewable energy. Manufacturers who strategically adopt these advanced robotic solutions will gain a decisive competitive edge in the era of digital transformation.