Robotic noise reduction technology represents a transformative advancement in modern automation, addressing the persistent challenge of unwanted sound emissions from machines. This field focuses on minimizing auditory disturbances in various robotic applications, from industrial manufacturing to personal service devices, enhancing both operational efficiency and human comfort. As robots become ubiquitous in daily life, noise pollution emerges as a critical concern, potentially causing workplace fatigue, reduced productivity, and regulatory non-compliance. Consequently, innovations in this area are gaining momentum, driven by the need for quieter, more harmonious human-robot interactions.

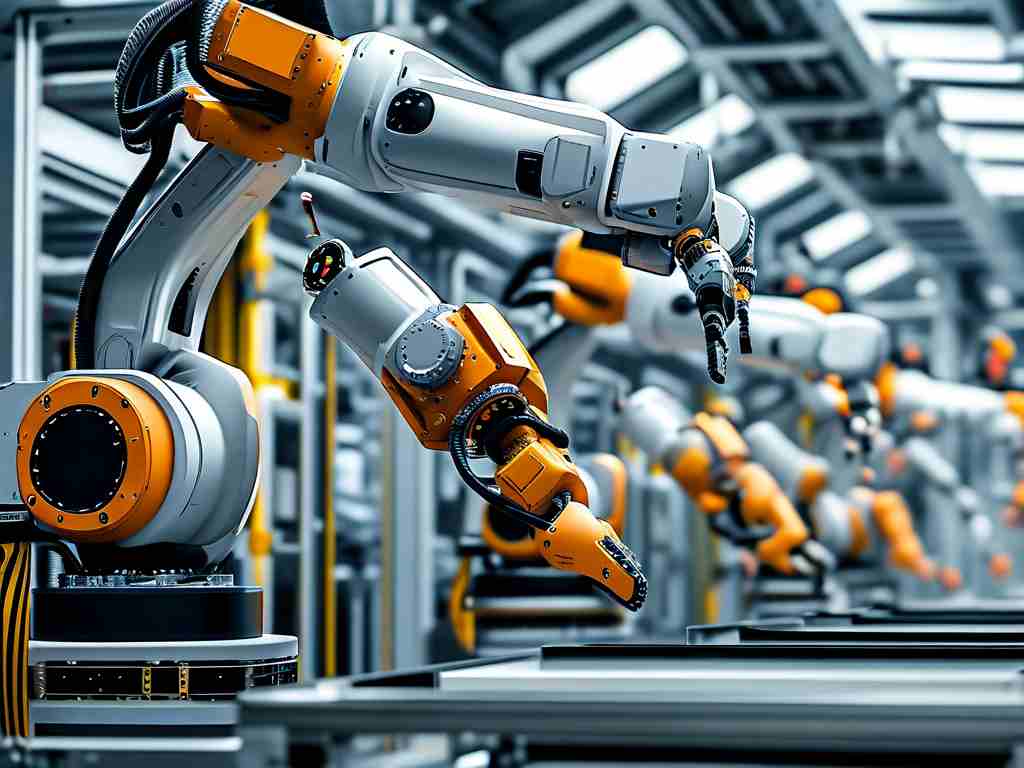

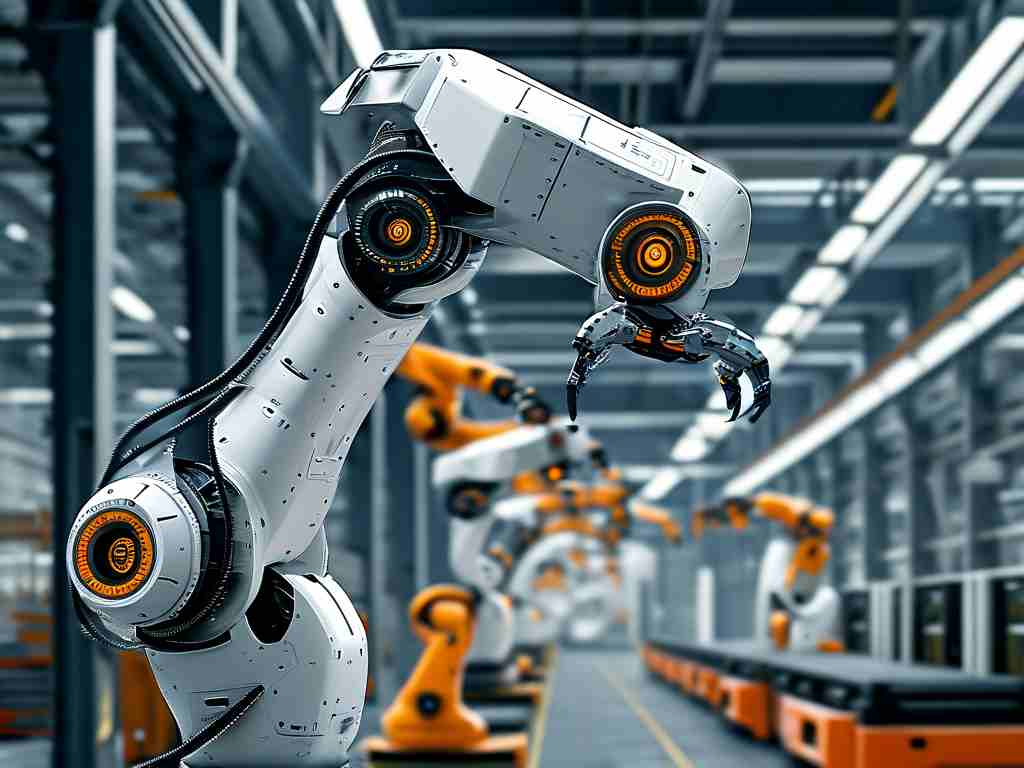

The core of robotic noise reduction lies in two primary approaches: active and passive methods. Active noise cancellation, often abbreviated as ANC, employs sophisticated sensors and algorithms to detect ambient sound waves in real time. By generating inverse acoustic signals, these systems counteract and neutralize noise at its source. For example, in industrial settings, robots equipped with ANC can suppress the hum of motors during assembly lines, creating a safer environment for workers. This technology relies on microprocessors that analyze frequency patterns and adapt swiftly, ensuring minimal latency in noise suppression. On the other hand, passive techniques involve physical modifications, such as incorporating sound-absorbing materials like specialized foams or composites into robot designs. These materials dampen vibrations and absorb acoustic energy, reducing noise propagation without electronic intervention. Combining both strategies yields optimal results, as seen in collaborative robots where low-decibel operation is essential for shared human workspaces.

Recent breakthroughs have propelled robotic noise reduction into new realms, with AI and machine learning playing pivotal roles. Advanced algorithms now enable robots to learn from environmental noise profiles, predicting and mitigating disturbances before they escalate. For instance, in autonomous delivery robots navigating urban streets, AI-driven systems can distinguish between routine operational sounds and excessive noise, adjusting components like gear mechanisms on-the-fly. This adaptability not only cuts noise levels by up to 50% in some cases but also extends the lifespan of robotic parts by reducing wear from vibrations. Additionally, material science innovations contribute significantly, with researchers developing lightweight, durable coatings that insulate against sound while maintaining robot agility. Such progress underscores the interdisciplinary nature of this field, merging robotics with acoustics and data science for holistic solutions.

Applications of robotic noise reduction span diverse sectors, demonstrating its broad impact. In healthcare, surgical robots benefit immensely from quiet operation, minimizing distractions during delicate procedures and improving patient outcomes. Similarly, service robots in hospitality or retail settings operate discreetly, enhancing customer experiences without intrusive background noise. Industrial automation sees substantial gains, as quieter robots comply with stringent occupational safety standards, reducing the risk of hearing damage in factories. Moreover, emerging areas like drone technology and smart home assistants leverage noise reduction to ensure seamless integration into daily life. For example, household cleaning robots with optimized noise control can run overnight without disrupting sleep, showcasing how this technology fosters convenience and well-being. These real-world implementations highlight the tangible benefits, from cost savings through reduced energy consumption to societal advantages like lower urban noise pollution levels.

Despite its promise, robotic noise reduction faces notable challenges that require ongoing attention. Cost remains a barrier, as integrating high-end ANC systems or premium materials can escalate production expenses, limiting accessibility for smaller enterprises. Complexity in design and calibration also poses hurdles, especially for robots operating in dynamic environments where noise sources vary unpredictably. Engineers must balance noise reduction with other performance metrics, such as speed and payload capacity, to avoid compromises. Furthermore, regulatory frameworks are evolving, with agencies like the International Organization for Standardization developing guidelines for acceptable noise levels in robotics, necessitating continuous innovation to meet compliance. Looking ahead, future trends point toward sustainable and intelligent solutions, such as energy-harvesting noise dampers that convert acoustic energy into power, or swarm robotics where multiple units coordinate to cancel collective noise. AI advancements will likely enable predictive maintenance, identifying noise issues before failures occur, thus driving reliability and adoption.

In , robotic noise reduction technology stands as a cornerstone of next-generation automation, offering profound improvements in efficiency, safety, and user satisfaction. By harnessing cutting-edge techniques, from AI-enhanced active systems to eco-friendly passive designs, this field paves the way for quieter, more responsive robots. As research accelerates, expect broader applications in smart cities and beyond, ultimately fostering a world where machines operate in near silence. This evolution not only mitigates environmental noise but also strengthens the bond between humans and robotics, ensuring that technological progress aligns with quality of life. Continued investment and innovation will be key to overcoming current limitations, solidifying noise reduction as an indispensable element in the robotics landscape for years to come.