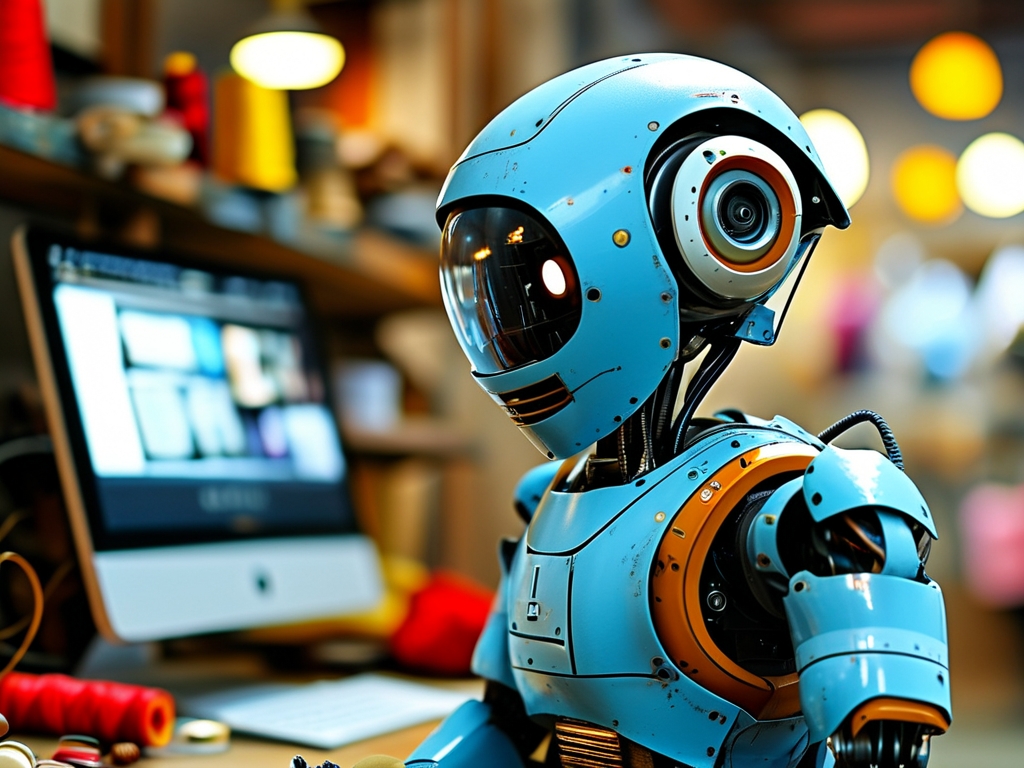

The textile and apparel industries have undergone transformative changes in recent decades, but few advancements are as groundbreaking as robotic automated sewing technology. This innovation, showcased vividly in instructional and promotional videos, is redefining efficiency, precision, and scalability in garment production. By integrating robotics, artificial intelligence, and advanced machinery, automated sewing systems are addressing long-standing challenges in manufacturing while opening doors to new possibilities.

The Mechanics of Robotic Automated Sewing

At its core, robotic automated sewing technology employs programmable robotic arms equipped with specialized sewing heads, guided by computer vision and machine learning algorithms. These systems analyze fabric types, stitch patterns, and design specifications to execute tasks with minimal human intervention. High-resolution videos of these robots in action reveal their ability to handle delicate materials like silk or stretchy knits without distortion—a feat that even skilled human workers may struggle with. For instance, a widely circulated demonstration video by SoftWear Automation Inc. shows robots sewing a T-shirt in under two minutes, flawlessly aligning seams and adjusting tension dynamically.

Why Video Matters in Showcasing Innovation

Video documentation plays a pivotal role in demystifying this technology. Unlike static diagrams or written manuals, videos capture the fluidity and speed of robotic sewing systems. They highlight critical features:

- Precision: Close-up footage reveals how robots insert needles with micron-level accuracy, reducing material waste.

- Adaptability: Clips of robots switching between fabrics—from denim to lace—demonstrate their versatility.

- Scalability: Time-lapse videos of factory setups illustrate how automated systems operate 24/7, slashing production timelines.

One notable example is the viral video by Siemens AG, which juxtaposes traditional sewing lines with robotic counterparts. The side-by-side comparison underscores a 300% increase in output and a 50% reduction in defects, making a compelling case for adoption.

Industry Impact and Applications

Automated sewing technology is not limited to fast fashion. Its applications span:

- Customized Apparel: Brands like Adidas use robotic systems to create personalized sneakers, captured in promotional videos that emphasize "mass customization."

- Automotive and Aerospace: Videos from companies like Tesla showcase robots sewing car seat upholstery with fire-resistant threads, ensuring consistency critical for safety standards.

- Medical Textiles: Surgical gowns and masks produced by automated systems meet stringent hygiene requirements, as seen in FDA-approved factory tour videos.

The technology also addresses labor shortages. Countries like Japan and Germany, facing aging workforces, have invested heavily in robotic sewing solutions. A documentary-style video by Mitsubishi Electric features a fully automated factory in Osaka, where robots handle 90% of garment production, from cutting to final stitching.

Challenges and Ethical Considerations

Despite its promise, the shift to automation raises concerns. Videos shared by labor unions highlight potential job displacement in regions like Bangladesh and Vietnam, where textile work employs millions. While proponents argue that robots will create higher-skilled tech roles, the transition remains contentious.

Technical hurdles also persist. For example, a troubleshooting video by Boston Dynamics reveals that highly textured fabrics (e.g., 3D-knit materials) still challenge robotic grippers. Overcoming these issues requires ongoing R&D, as seen in academic videos from MIT’s Computer Science and AI Lab, where researchers train robots using simulated fabric behavior.

The Future: AI-Driven Design Integration

Emerging trends suggest a future where robotic sewing systems collaborate with AI design tools. In a TED Talk video, fashion designer Iris van Herpen demonstrates how AI-generated patterns are directly fed to sewing robots, enabling real-time prototyping. Similarly, Nike’s 2023 sustainability campaign video features robots upcycling scrap fabric into new garments—a process guided by AI algorithms that minimize waste.

Robotic automated sewing technology, amplified by video storytelling, is more than a manufacturing upgrade—it’s a paradigm shift. As videos continue to educate stakeholders and inspire innovation, the fusion of robotics and textiles promises a future where production is faster, greener, and infinitely adaptable. Yet, balancing technological progress with social responsibility will remain key to ensuring equitable growth in this new industrial era.