The evolution of high-precision robotic control systems has revolutionized industries ranging from manufacturing to healthcare. By integrating advanced algorithms, sensor fusion, and real-time feedback mechanisms, modern robots now achieve micron-level accuracy, enabling tasks previously deemed impossible for automated systems. This article explores the core technologies driving this progress, their practical applications, and emerging challenges in the field.

At the heart of high-precision robotics lies motion control architecture. Traditional PID controllers have given way to adaptive neural networks that dynamically adjust parameters based on environmental variables. For instance, in semiconductor manufacturing, robots equipped with self-calibrating actuators maintain positioning accuracy within 0.1 micrometers despite temperature fluctuations. A recent case study at TSMC revealed that implementing model-predictive control (MPC) algorithms reduced wafer-handling errors by 42% compared to legacy systems.

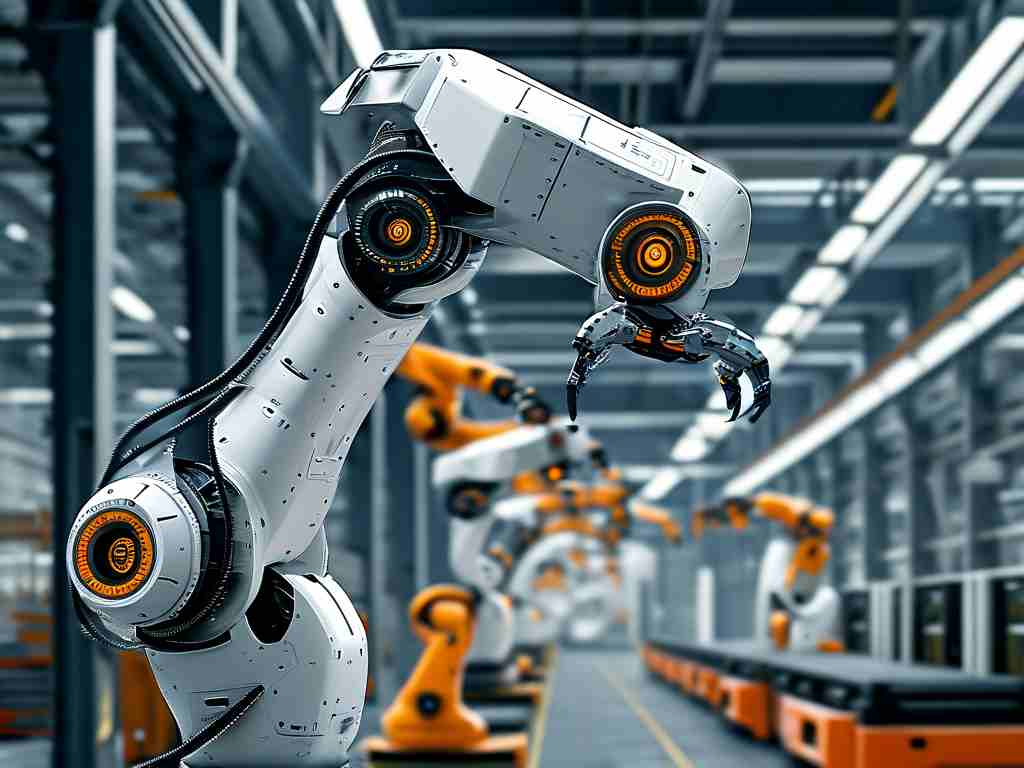

Sensor integration plays an equally critical role. Multi-axis force-torque sensors combined with vision systems now enable closed-loop correction at frequencies exceeding 10 kHz. The ABB YuMi collaborative robot demonstrates this through its ability to thread needles autonomously—a task requiring sub-millimeter precision. By cross-referencing data from laser triangulation sensors and RGB-D cameras, the system achieves real-time path correction with 99.8% repeatability.

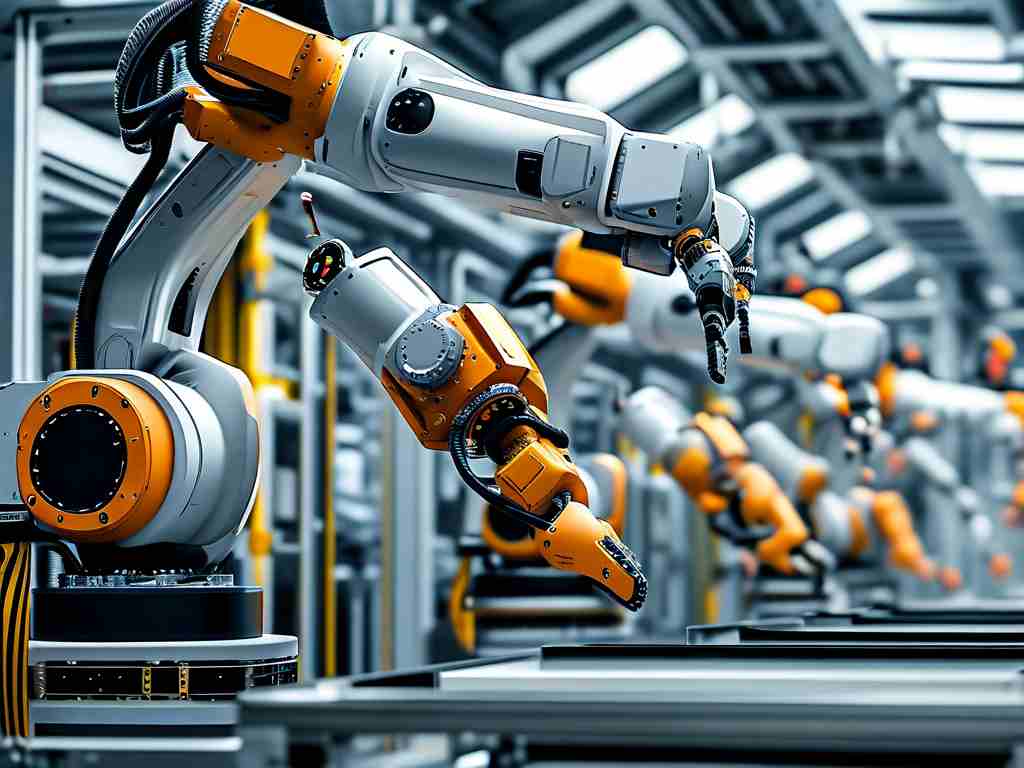

Industrial applications showcase these advancements vividly. Automotive assembly lines employ seven-axis robots with torque ripple compensation to install engine components with tolerances under 5 microns. In contrast, medical robotics leverages haptic feedback controls for microsurgical procedures. The da Vinci Surgical System, for example, filters surgeon hand tremors at 500 Hz while scaling movements down to a 3:1 ratio, enabling procedures on blood vessels smaller than 1 mm in diameter.

However, achieving such precision introduces computational challenges. Real-time operating systems (RTOS) like ROS-Industrial now support deterministic latency below 50 μs, but hardware-software co-design remains crucial. FPGA-accelerated control loops have become standard in high-end systems, as seen in KUKA’s KR CYBERTECH series. The following pseudo-code illustrates a simplified torque control loop:

void TorqueControl() {

readJointSensors();

calculateError(currentTorque, targetTorque);

adjustPWM(feedforward + PID_Compute(error));

if (vibrationDetected()) applyNotchFilter();

}

Emerging technologies like quantum sensing and edge AI promise further improvements. Researchers at MIT recently demonstrated a gripper using quantum diamond sensors to measure grip force at nanonewton resolutions. Meanwhile, NVIDIA’s Isaac Sim platform enables physics-based training of control models in virtual environments, reducing real-world calibration time by 70%.

Despite these strides, industry adoption faces barriers. Precision robotics often requires specialized maintenance and recalibration protocols. A 2023 survey by the International Federation of Robotics noted that 68% of manufacturers cite “skill gaps in precision system troubleshooting” as a key adoption hurdle. Solutions are emerging through augmented reality (AR) interfaces that guide technicians through alignment procedures using holographic overlays.

The future trajectory points toward autonomous precision. Boston Dynamics’ latest Atlas robot incorporates proprioceptive perception to adjust foot placement mid-stride with 0.2-degree angular accuracy. As 5G-enabled cloud robotics matures, expect to see distributed control systems where offboard supercomputers optimize motion plans for entire fleets of factory robots simultaneously.

In , high-precision robotic control represents not just incremental improvement but a paradigm shift in automation capabilities. From enabling minimally invasive surgeries to assembling quantum computing components, these technologies continue to redefine the boundaries of mechanical systems. As processing power and sensor fidelity advance, the next decade will likely witness robots operating at scales and accuracies that today exist only in theoretical models.