Autonomous Mobile Robots, commonly known as AMRs, represent a cutting-edge evolution in material handling systems, transforming how industries manage logistics with their intelligent navigation and adaptability. Unlike older automated guided vehicles that rely on fixed paths like wires or magnets, AMRs operate independently using sophisticated sensors and software, enabling them to navigate dynamic environments seamlessly. This technology has surged in popularity due to its ability to boost efficiency, reduce operational costs, and enhance workplace safety across sectors such as manufacturing, warehousing, and healthcare. At the heart of AMR functionality lies advanced perception systems. These robots employ a combination of LiDAR (Light Detection and Ranging) scanners, high-resolution cameras, and ultrasonic sensors to create real-time maps of their surroundings. For example, LiDAR emits laser pulses to measure distances, building a 3D model that helps the robot detect obstacles like pallets or humans and adjust its path instantly. This is powered by algorithms such as SLAM (Simultaneous Localization and Mapping), which allows AMRs to pinpoint their location accurately within a facility while continuously updating the map as they move. Such capabilities eliminate the need for extensive infrastructure modifications, making AMRs a cost-effective solution for businesses aiming to modernize without halting operations.

The autonomy of AMRs stems from their integration with artificial intelligence and machine learning. These robots can analyze data from their sensors to make split-second decisions, such as rerouting around a spill or coordinating with other AMRs to avoid congestion. This intelligence is often managed through centralized fleet management software, where operators monitor multiple units via a dashboard, assigning tasks like transporting goods from a loading dock to storage shelves. In practical terms, this translates to significant productivity gains. Warehouses deploying AMRs report faster order fulfillment rates, as the robots work around the clock without fatigue, handling repetitive tasks that once required human labor. Moreover, AMRs enhance safety by incorporating fail-safes; for instance, they automatically halt if they sense a person nearby, reducing accident risks in busy industrial settings. This blend of efficiency and safety has driven widespread adoption in e-commerce giants like Amazon, where AMRs streamline inventory management by autonomously moving items across vast fulfillment centers, cutting down processing times by up to 50% in some cases.

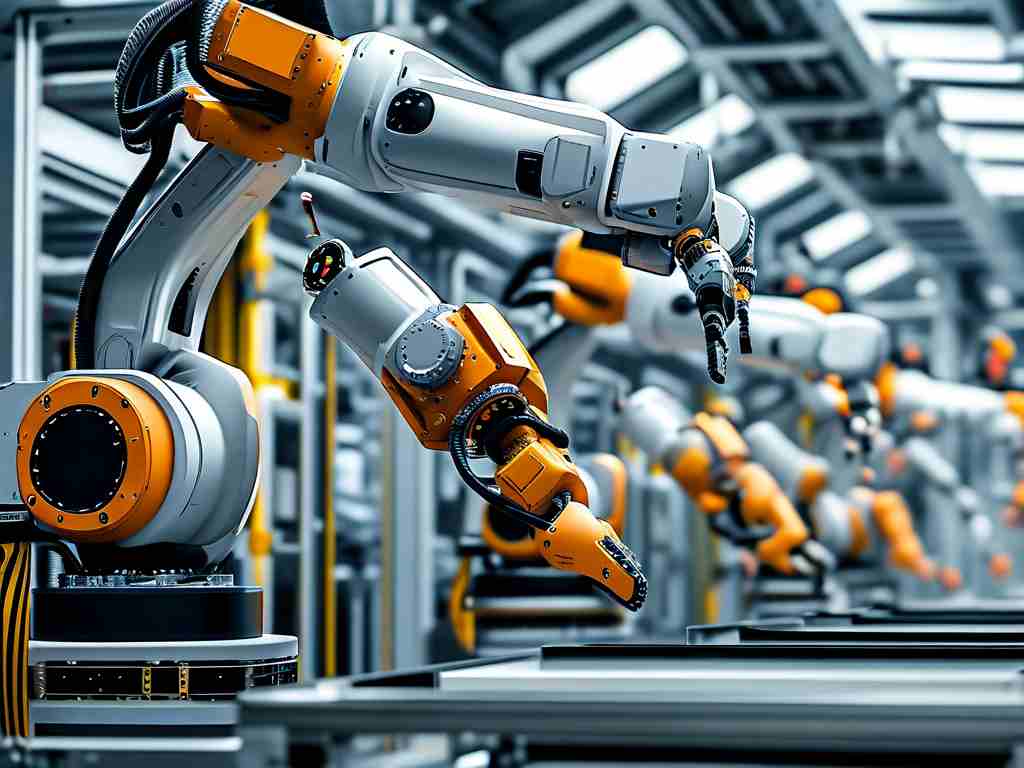

Beyond logistics, AMR technology finds applications in diverse fields. In manufacturing plants, these robots transport raw materials between assembly lines, optimizing workflows and minimizing downtime. Hospitals utilize them for delivering medical supplies, such as medications or linens, allowing staff to focus on patient care rather than mundane errands. The flexibility of AMRs also shines in environments with frequent layout changes, as they can adapt to new configurations without reprogramming, unlike traditional systems. However, challenges remain, particularly concerning cybersecurity and initial implementation costs. As AMRs connect to networks for updates and coordination, they become vulnerable to hacking threats, necessitating robust encryption and regular software patches. Additionally, the upfront investment in AMR systems can be substantial, though long-term savings from reduced labor and energy consumption often justify the expense. Looking ahead, the future of AMR technology promises even greater innovation, with trends like 5G connectivity enabling faster data transfer for real-time decision-making and the rise of collaborative robots that work alongside humans more intuitively. Industry experts predict that as AI algorithms improve, AMRs will handle more complex tasks, such as predictive maintenance by identifying equipment issues before failures occur.

In essence, AMR transport robots are reshaping material handling by offering scalable, intelligent solutions that drive operational excellence. Their ability to learn from environments and collaborate autonomously positions them as a cornerstone of Industry 4.0, fostering smarter, more resilient supply chains. As research continues, we can anticipate broader accessibility and enhanced capabilities, making AMRs indispensable tools for businesses striving to thrive in an automated world.