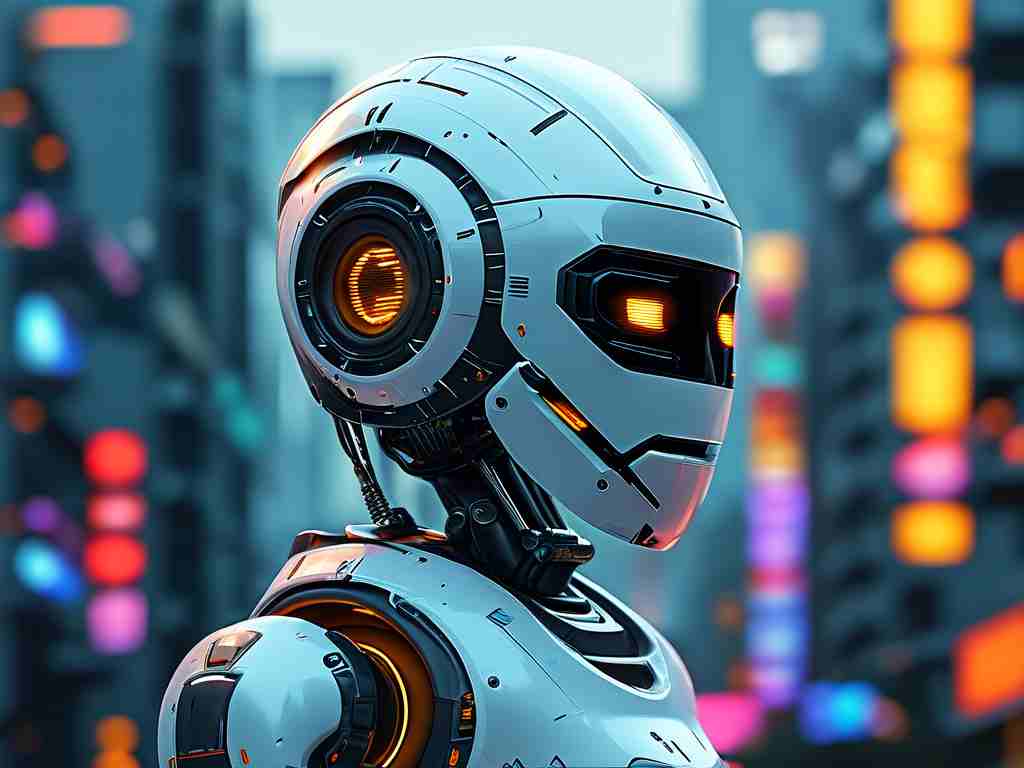

In modern industrial environments, factory inspection robots have become indispensable tools for enhancing operational efficiency and ensuring workplace safety. These autonomous systems are designed to perform repetitive monitoring tasks with precision, reducing human exposure to hazardous conditions. However, developing a reliable inspection robot requires adherence to specific technical criteria to meet diverse industrial demands.

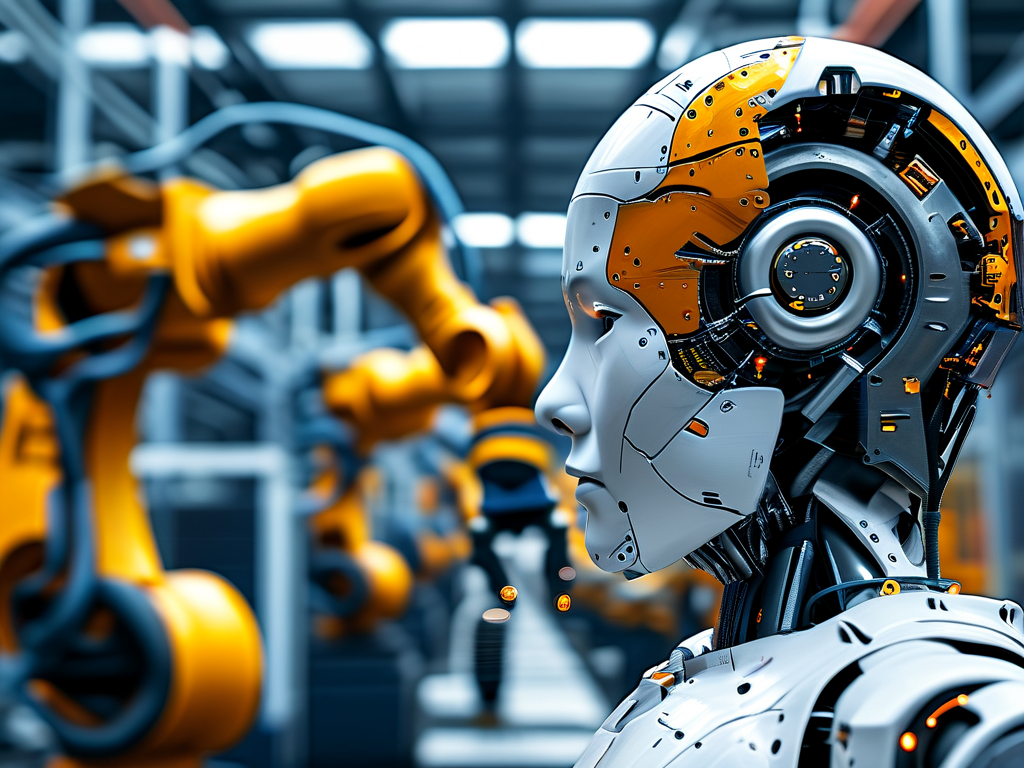

Sensor Integration and Accuracy

A core requirement for factory inspection robots is advanced sensor integration. High-resolution cameras, thermal imaging sensors, and LiDAR systems enable real-time data collection for detecting anomalies such as equipment overheating, structural cracks, or gas leaks. For instance, thermal sensors must achieve a temperature resolution of at least ±0.5°C to identify subtle variations in machinery performance. Additionally, ultrasonic sensors are often deployed to measure distances in cluttered environments, ensuring collision-free navigation.

Navigation and Mobility

Robust navigation capabilities are critical for robots operating in dynamic factory settings. Simultaneous Localization and Mapping (SLAM) algorithms allow robots to create and update maps of unfamiliar environments autonomously. To handle uneven floors or obstacles, a combination of wheeled and tracked mobility systems is recommended. For example, omnidirectional wheels paired with adaptive suspension can navigate thresholds up to 3 cm in height, while maintaining stability on oily or slippery surfaces.

Data Processing and Communication

Real-time data processing is essential for timely decision-making. Edge computing modules embedded in the robot can preprocess sensor data locally, reducing latency compared to cloud-dependent systems. A minimum of 8 GB RAM and a quad-core processor are typically required to handle simultaneous video analysis and wireless communication. For seamless integration with factory networks, support for industrial protocols like Modbus TCP or OPC UA is mandatory.

Power Management

Extended operational uptime is achieved through optimized power management. Lithium-ion batteries with a capacity of 20 Ah or higher ensure 8-10 hours of continuous operation. Fast-charging technology, such as 100W USB-PD, enables 80% recharge within 45 minutes. Some designs incorporate solar panels for supplementary energy harvesting in well-lit facilities.

Environmental Resilience

Factory robots must withstand harsh conditions, including temperature extremes (-10°C to 50°C), particulate matter, and moisture. An IP67-rated enclosure protects internal components from dust ingress and temporary water immersion. Conformal coating on circuit boards adds an extra layer of defense against corrosive chemicals commonly found in manufacturing plants.

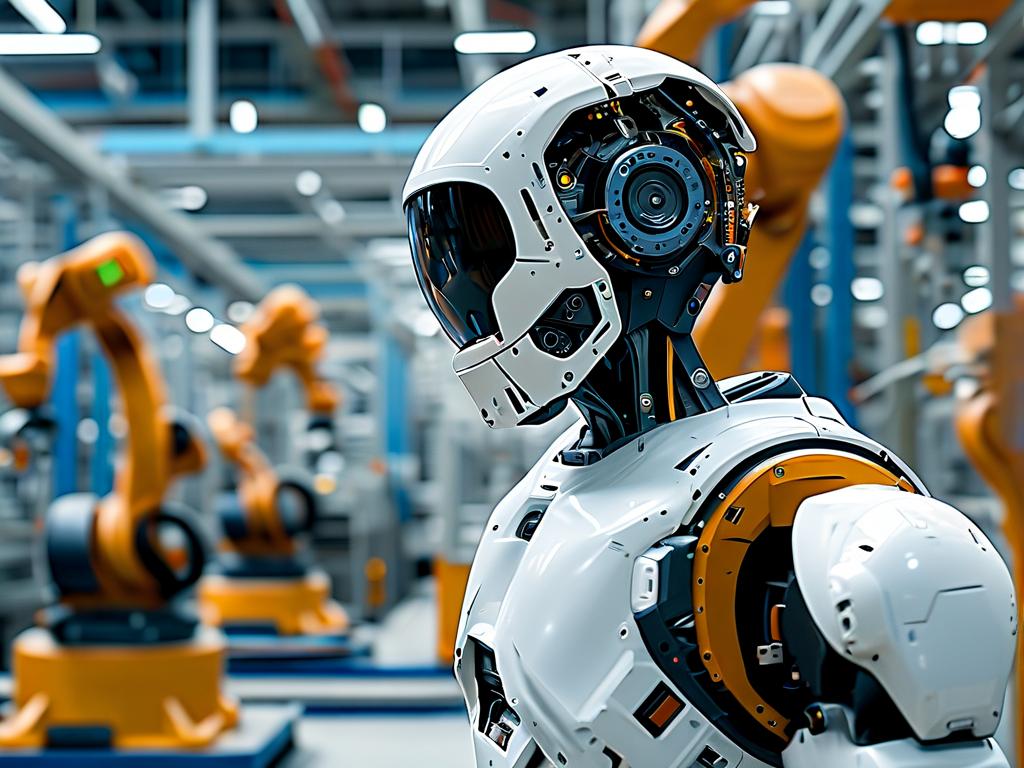

Safety Compliance

Adherence to ISO 10218-2 and ANSI/RIA R15.08 standards ensures safe human-robot collaboration. Emergency stop buttons, proximity sensors with a 2-meter detection range, and fail-safe braking systems are non-negotiable features. Acoustic alarms emitting 85 dB tones provide audible warnings during autonomous movements.

A case study from an automotive assembly plant demonstrates these principles in action. After deploying inspection robots with 360-degree camera arrays and methane detectors, the facility reduced equipment downtime by 37% and eliminated three potential fire hazards within the first quarter of implementation.

Future advancements may integrate AI-powered predictive maintenance, where robots analyze historical data patterns to forecast equipment failures. However, current technical priorities remain focused on refining sensor fusion accuracy and improving energy efficiency. By meeting these specifications, factory inspection robots will continue to play a pivotal role in shaping smart manufacturing ecosystems.