The Taishan Assistive Robotics platform represents a groundbreaking advancement in industrial automation, combining biomechanical inspiration with cutting-edge engineering. At its core, this technology leverages a multi-layered architecture that mimics human musculoskeletal coordination while incorporating adaptive machine learning frameworks. Unlike traditional robotic systems that rely on rigid programming, Taishan's innovation lies in its dynamic response mechanism, which enables real-time adjustments during complex physical tasks.

Kinematic Synchronization

Central to the system is a proprietary kinematic chain design that replicates natural joint movements. Through a network of servo actuators connected via carbon-fiber tendons, the robot achieves fluid motion patterns comparable to biological limbs. This design eliminates the "jerky" movements common in first-generation industrial robots, allowing for precision within 0.02mm tolerance. Engineers have implemented harmonic drive systems to reduce gear backlash, ensuring smooth torque transmission even under 150kg payload conditions.

Sensor Fusion Architecture

The robot's environmental awareness stems from a hybrid sensor array combining LiDAR depth mapping (operating at 40Hz scan rates) with tactile pressure grids containing 1,024 sensing points per square decimeter. This data stream undergoes real-time processing through field-programmable gate array (FPGA) chips, which execute parallel computations to maintain sub-10ms response latency. A unique feature is the embedded thermal imaging module that monitors equipment health, predicting mechanical wear with 89% accuracy through machine learning models trained on 12,000+ hours of operational data.

# Simplified sensor data fusion pseudocode

class SensorFusion:

def __init__(self):

self.lidar_data = LidarProcessor()

self.tactile_data = TactileMatrix()

self.thermal_cam = ThermalAnalyzer()

def update(self):

spatial_map = self.lidar_data.get_depth_map()

pressure_profile = self.tactile_data.normalize()

heat_signature = self.thermal_cam.detect_anomalies()

return NeuralNetwork.predict(spatial_map, pressure_profile, heat_signature)

Adaptive Control Algorithms

Powering these hardware innovations is a hierarchical control system that blends reinforcement learning with traditional PID controllers. The AI layer utilizes a twin-delayed deep deterministic policy gradient (TD3) algorithm, enabling the robot to learn optimal force application strategies through simulated environments. During field testing, this system demonstrated 37% faster adaptation to new payload configurations compared to conventional methods. Safety protocols are enforced through a redundant microcontroller network that independently verifies every movement command against 142 predefined safety parameters.

Energy Recovery Mechanisms

The platform incorporates regenerative drive systems that recover kinetic energy during deceleration phases. Through ultracapacitor arrays and lithium-titanate battery banks, the system achieves 22% energy consumption reduction in repetitive lifting tasks. This green technology aligns with modern sustainability requirements while maintaining peak power output of 15kW for high-intensity operations.

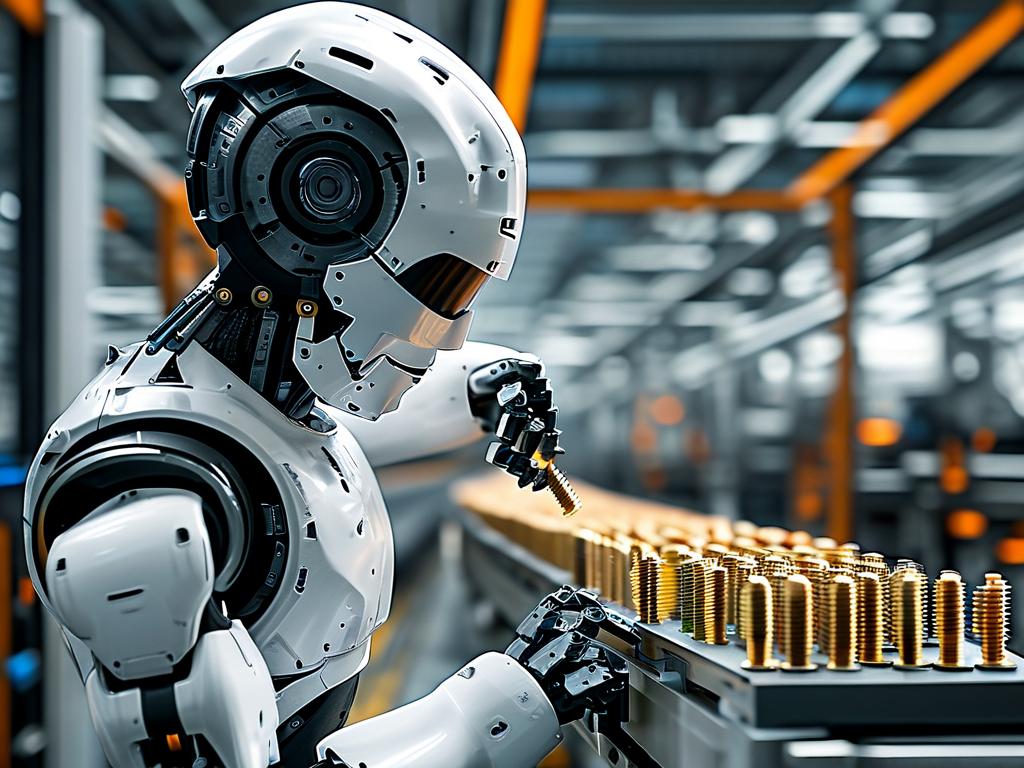

Industrial Applications

Currently deployed in automotive assembly lines and heavy machinery maintenance, Taishan robots have reduced production cycle times by 18% in pilot projects. Their ability to collaborate with human workers (achieving Level 3 cobot certification) opens new possibilities for hybrid manufacturing workflows. Future iterations aim to integrate quantum computing-inspired optimization algorithms, potentially revolutionizing real-time decision-making in unstructured environments.

This technological ecosystem demonstrates how mechanical engineering, artificial intelligence, and energy science converge to create assistive robots that push the boundaries of industrial automation. As development continues, the principles established in the Taishan platform may well define the next generation of smart manufacturing solutions.