The integration of robotic screw handling systems has emerged as a transformative force in modern manufacturing ecosystems. By combining precision engineering with adaptive automation, this technology addresses critical challenges in assembly-line efficiency while reshaping traditional production paradigms.

Core Mechanism and Workflow

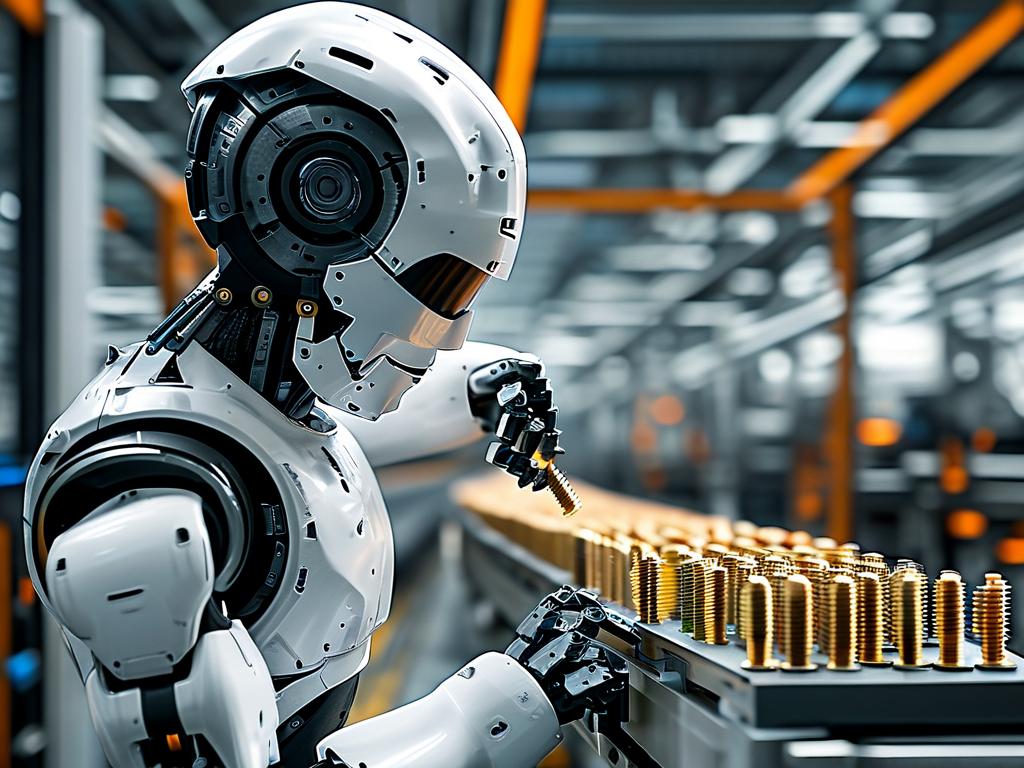

At the heart of robotic screw automation lies a synchronized interplay between vision-guided positioning and dynamic torque control. Advanced machine vision systems equipped with high-resolution cameras scan workpieces to identify fastener locations within micrometer-level accuracy. These coordinates are then relayed to multi-axis robotic arms fitted with specialized end-effectors capable of handling screws ranging from M1.2 micro-fasteners to large structural bolts.

The process initiates with automated screw feeding mechanisms that orient fasteners through vibration sorting or magnetic alignment. Pneumatic or electric drivers mounted on robotic manipulators then execute precise insertion sequences, incorporating real-time torque feedback to prevent cross-threading or component damage. Modern systems integrate self-learning algorithms that adapt to material variations and environmental fluctuations, such as thermal expansion in metal components.

Industrial Applications

Automotive manufacturing plants have adopted robotic screw handling for engine block assembly, where systems achieve cycle times of 2.8 seconds per fastener with zero defect rates. In consumer electronics production, collaborative robots (cobots) work alongside human technicians to install delicate components in smartphones and laptops, demonstrating 99.98% placement accuracy.

Aerospace applications present unique challenges, with robots handling titanium alloy screws in confined fuselage compartments. These systems utilize carbon fiber-reinforced end effectors and anti-static coatings to maintain operational integrity in sensitive environments. Recent deployments in renewable energy sectors show promise, particularly in solar panel frame assembly where corrosion-resistant fasteners require specific installation protocols.

Technical Advancements

Breakthroughs in haptic feedback systems now enable robots to simulate human tactile sensitivity during screw engagement. Force-torque sensors combined with predictive analytics allow immediate adjustment of insertion angles, significantly reducing error margins. The development of hybrid pneumatic-electric drivers has improved energy efficiency by 40% compared to conventional systems.

Cloud-connected automation platforms enable real-time monitoring across multiple production lines, with machine learning models analyzing historical data to optimize screw sequencing patterns. A notable innovation involves magnetic levitation feeding systems that eliminate mechanical contact, reducing part wear by 75% in high-volume operations.

Economic and Operational Impact

Implementation studies across 12 manufacturing sectors reveal an average 34% reduction in assembly labor costs and 19% improvement in production throughput. Quality control metrics show 62% fewer fastener-related defects compared to manual operations. The technology's scalability allows seamless integration with existing Industry 4.0 infrastructure, particularly when combined with IoT-enabled torque analyzers and digital twin simulations.

Environmental benefits are emerging as manufacturers report 28% less material waste through precise screw length selection and optimized tightening parameters. Energy consumption metrics demonstrate 22% reduction per unit produced, achieved through smart power management in driver systems.

Implementation Considerations

Successful deployment requires careful analysis of screw specifications, including head type, thread pitch, and material composition. Production engineers must account for workspace ergonomics when programming robot trajectories, particularly in mixed-model assembly environments. Regular calibration of vision systems and torque sensors remains critical, with recommended maintenance intervals of 500 operating hours.

Training programs for technical staff should emphasize hybrid skill development, combining traditional mechanical expertise with robotics programming literacy. Cybersecurity protocols must be prioritized for networked systems, especially those handling proprietary fastener designs or sensitive production data.

Future Development Trajectory

Research institutions are exploring quantum-enhanced vision systems capable of sub-micron measurement accuracy. The integration of biodegradable screw handling solutions aligns with circular economy initiatives, requiring novel material compatibility protocols. Emerging standards like ISO/TS 23187:2023 for robotic fastening systems are driving global harmonization of technical specifications.

As 5G-enabled edge computing becomes prevalent, expect to see decentralized control architectures where multiple robots collaboratively adjust screw patterns in real-time. The convergence of this technology with additive manufacturing may eventually enable on-demand fastener production directly at assembly stations.

This technological evolution positions robotic screw handling as both a strategic operational asset and a catalyst for reimagining industrial workflows. By continuously pushing the boundaries of precision and adaptability, automated fastening systems are fundamentally altering the economics of mass production while enabling new design possibilities in engineered products.