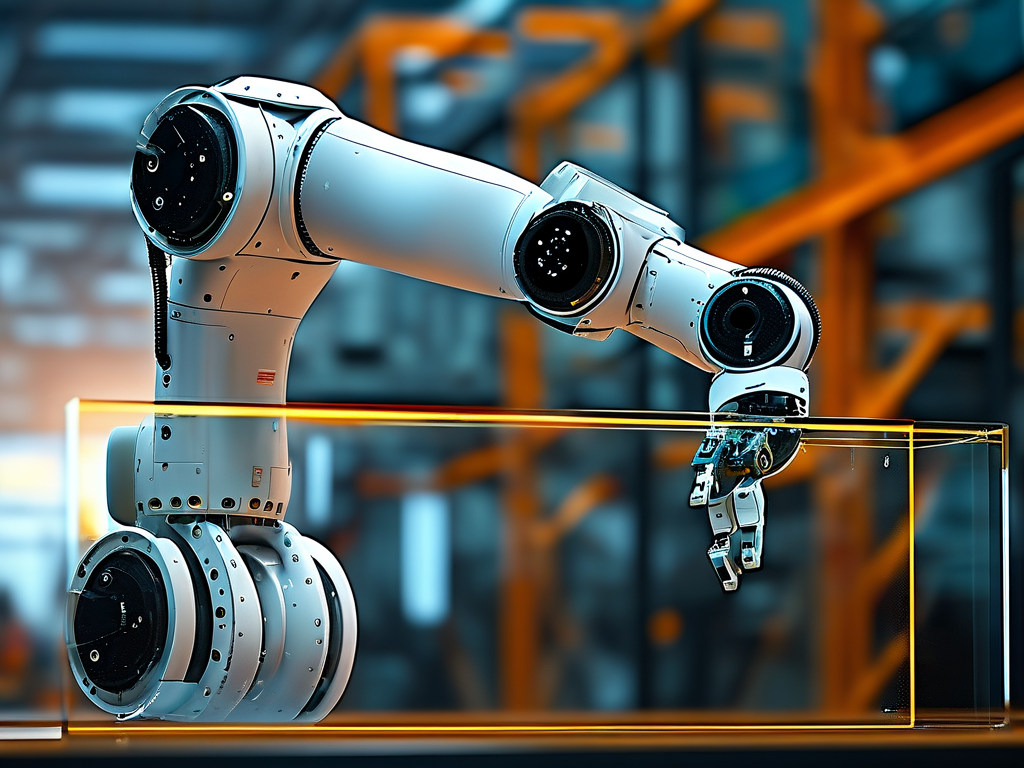

The construction and manufacturing sectors are witnessing a paradigm shift with the emergence of robotic glass installation systems. This cutting-edge technology combines precision engineering with artificial intelligence to address long-standing challenges in handling fragile materials. Unlike traditional manual methods that rely heavily on skilled labor, robotic systems offer unprecedented accuracy and repeatability, particularly in high-rise building projects where human safety risks are significant.

At the core of this innovation lies advanced computer vision technology. Equipped with multi-spectral sensors, these robots can scan glass panels at micrometer-level resolution, detecting microscopic imperfections invisible to the human eye. The system's machine learning algorithms analyze surface textures and structural integrity in real time, enabling instant quality assessments before installation. This capability not only reduces material waste but also ensures optimal performance of installed glass units.

One groundbreaking application comes from Shanghai-based TechGlaze Solutions, whose robotic installation arm recently completed a 48-story curtain wall project in half the conventional time. The system's adaptive suction mechanism, featuring dynamically adjustable pressure zones, allows secure handling of curved and irregularly shaped glass panels. Engineers have integrated predictive maintenance features that monitor wear patterns on suction cups and automatically schedule replacements, minimizing downtime.

Safety enhancements represent another critical advantage. Traditional glass installation accounts for 17% of construction-site injuries according to OSHA reports. Robotic systems eliminate direct human contact with heavy glass panels during lifting and positioning phases. The latest models incorporate collision-avoidance systems using LiDAR mapping, creating virtual safety buffers around both workers and delicate materials.

Economic implications are equally transformative. While initial investment costs remain substantial, lifecycle analysis shows 40% cost reduction over five years compared to manual methods. This calculation factors in reduced insurance premiums, lower worker compensation claims, and decreased material waste. Contractors using these systems report 30% faster project completion rates, translating to earlier occupancy permits and revenue generation for commercial developments.

Environmental sustainability aspects are gaining attention. Robotic precision minimizes glass cutting errors, reducing material consumption by an estimated 22%. Some systems now integrate recycled glass compatibility algorithms that optimize panel layouts to accommodate imperfect surfaces, pushing sustainability boundaries in architectural design.

The technology's evolution continues to accelerate. Munich-based RoboGlazier recently unveiled a hybrid system combining robotic precision with human oversight. This collaborative model allows technicians to guide robotic arms through augmented reality interfaces, blending human expertise with machine accuracy. Early adopters in Dubai's luxury construction market report 90% reduction in installation defects using this approach.

Despite these advancements, challenges persist. Industry adoption faces hurdles from union regulations and workforce retraining requirements. Material scientists are collaborating with robotics firms to develop next-generation glass composites specifically engineered for automated handling. Current research focuses on self-healing glass coatings that compensate for micro-abrasions caused during robotic manipulation.

Looking ahead, the integration of quantum computing with robotic installation systems promises to revolutionize large-scale architectural projects. Preliminary tests at MIT's Architecture Robotics Lab demonstrate potential for real-time structural simulations during installation, enabling dynamic adjustments based on environmental factors like wind patterns and thermal expansion.

As urban landscapes continue evolving with increasingly complex glass structures, robotic installation technology stands poised to redefine industry standards. From earthquake-resistant glass matrices in Tokyo to hurricane-proof installations in Miami, these intelligent systems are reshaping our built environment while addressing critical challenges in workforce safety and environmental stewardship.