The advent of robotic fueling technology is reshaping industries by automating one of the most routine yet critical tasks: refueling vehicles and machinery. This innovation combines robotics, artificial intelligence, and advanced sensor systems to create efficient, safe, and cost-effective solutions. As industries strive for higher productivity and sustainability, robotic fueling systems are emerging as a transformative force.

Evolution of Robotic Fueling Systems

Early iterations of automated fueling were limited to basic mechanical arms programmed for simple tasks. Today’s systems, however, integrate machine learning algorithms and real-time data analysis. For instance, modern robotic fuel dispensers can identify vehicle types, adjust nozzle positioning with millimeter precision, and monitor fuel levels without human intervention. Companies like RoboFuel Inc. have pioneered systems that use 3D vision cameras to detect fuel tank locations, even in complex environments like construction sites or airports.

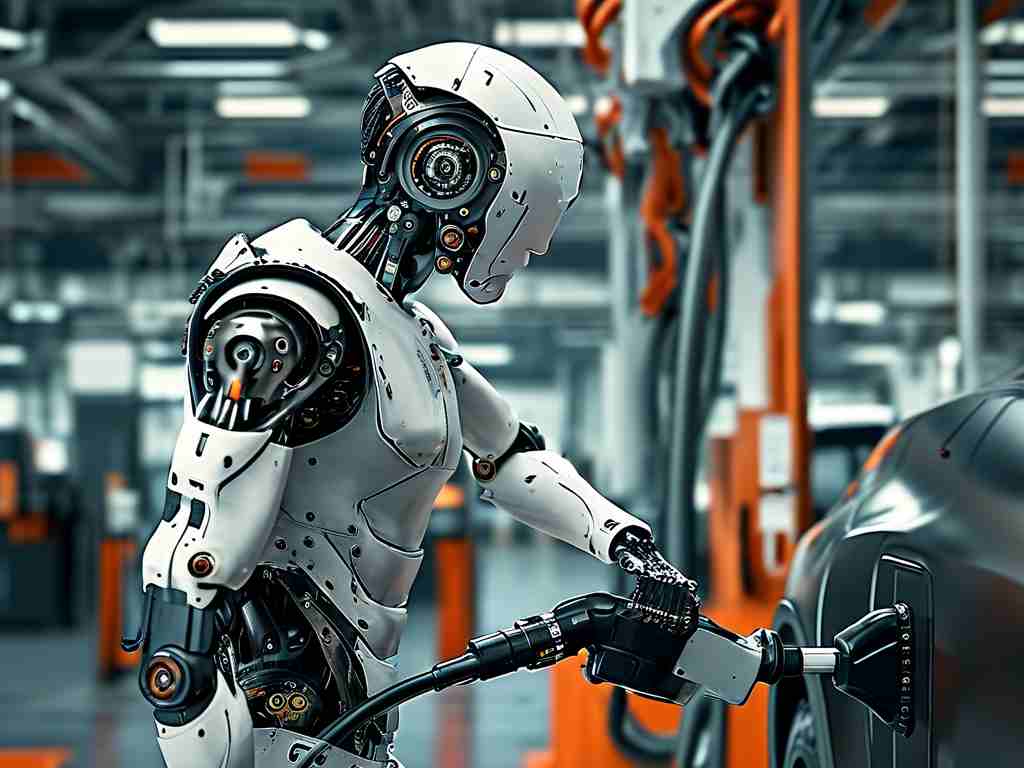

Applications Across Industries

The transportation sector has been a primary beneficiary. Autonomous gas stations equipped with robotic arms are already operational in countries like Japan and Germany, reducing wait times and minimizing human error. In aviation, drones equipped with fueling modules are being tested to service aircraft on tarmacs, cutting turnaround times by up to 40%. Similarly, agricultural machinery manufacturers are adopting robotic refueling units that operate in remote fields, ensuring uninterrupted workflow during harvest seasons.

Technical Advantages and Safety

Robotic fueling eliminates risks associated with manual handling, such as spills or exposure to hazardous fumes. Sensors embedded in these systems detect leaks instantly and shut down operations, preventing environmental contamination. A case study from EnergySafe Solutions revealed that robotic fuel dispensers reduced workplace accidents by 62% in a pilot project at a European trucking hub. Additionally, these systems optimize fuel usage through precise measurement, curbing waste and lowering operational costs.

Challenges and Limitations

Despite their potential, robotic fueling technologies face hurdles. High initial investment costs remain a barrier for small businesses. Maintenance of intricate robotic components also demands specialized expertise, which can strain resources. Furthermore, regulatory frameworks lag behind technological advancements. For example, aviation authorities in some regions still prohibit fully autonomous drone-based fueling due to safety concerns. Addressing these issues requires collaboration between governments, tech developers, and industry stakeholders.

Future Trends and Sustainability

The next phase of robotic fueling innovation focuses on sustainability. Researchers are exploring hybrid systems that combine solar-powered robots with biofuel-compatible interfaces. A recent prototype by GreenTech Labs uses AI to calculate the carbon footprint of each refueling session, providing actionable insights for reducing emissions. Another emerging trend is the integration of blockchain technology to track fuel provenance and ensure ethical sourcing—a feature gaining traction in eco-conscious markets.

Robotic fueling technology is not merely a convenience but a necessity in an era prioritizing efficiency and sustainability. While challenges persist, ongoing advancements in AI and materials science promise to overcome current limitations. As industries increasingly adopt these systems, the day when robotic refueling becomes the global standard seems inevitable. From reducing human labor risks to enabling greener practices, this technology is fueling a smarter future—one automated drop at a time.