The evolution of robotic motor control technologies has become a cornerstone of modern automation systems, enabling machines to perform complex tasks with unprecedented accuracy. At its core, this technology revolves around the precise regulation of torque, speed, and position in electric motors—a critical requirement for applications ranging from industrial assembly lines to surgical robots. This article explores the latest innovations in motor control methodologies, their real-world implementations, and the challenges engineers face in optimizing performance.

Foundations of Motor Control Systems

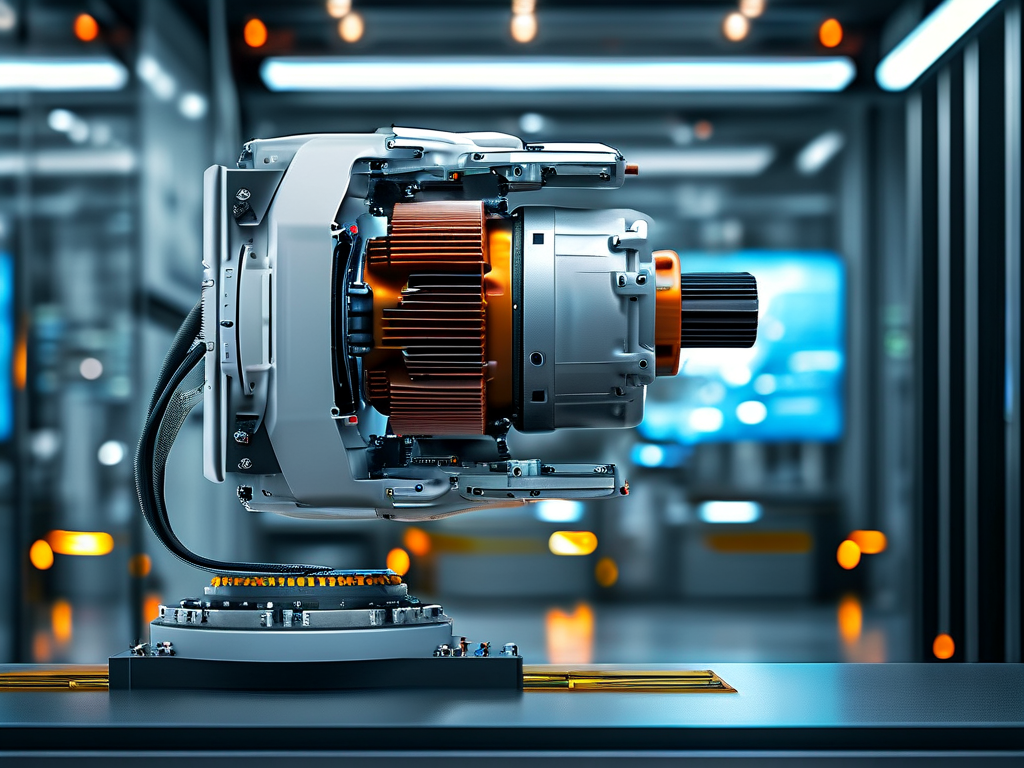

Modern robotic systems predominantly rely on three-phase brushless DC (BLDC) motors and servo motors due to their high torque-to-weight ratios and energy efficiency. The control architecture typically integrates microcontrollers or digital signal processors (DSPs) running advanced algorithms. Field-Oriented Control (FOC), also known as vector control, has emerged as a gold standard for achieving smooth operation across varying loads. By decoupling stator current into magnetic flux and torque components, FOC enables dynamic adjustments comparable to the responsiveness of DC motors.

A practical implementation often involves sensor fusion techniques. For instance, incremental encoders provide real-time positional feedback, while inertial measurement units (IMUs) compensate for external disturbances. Consider a collaborative robot arm in a manufacturing setting: its joints require torque accuracy within ±0.5% to handle delicate components. Here, sensorless control algorithms—which estimate rotor position through back-electromotive force (EMF) analysis—reduce hardware complexity while maintaining sub-degree angular precision.

Algorithmic Innovations

Recent breakthroughs in control theory have introduced adaptive PID controllers with self-tuning capabilities. Unlike traditional proportional-integral-derivative (PID) systems, these variants employ machine learning models to predict load variations. A case study from automotive welding robots demonstrates a 22% reduction in settling time when using neural network-assisted PID loops compared to fixed-gain configurations.

Model Predictive Control (MPC) represents another frontier. By evaluating multiple potential control sequences in a receding time horizon, MPC optimizes for both immediate performance and long-term energy efficiency. Experimental data from quadrupedal robots shows MPC-based motor controllers achieving 15% better power utilization during dynamic gait transitions compared to classical methods.

Hardware-Software Convergence

The rise of System-on-Chip (SoC) designs has blurred the line between control circuitry and computational units. Modern motor drivers now embed ARM Cortex-M7 cores capable of executing control loops at 10 kHz frequencies. This integration minimizes communication latency—a crucial factor for swarm robotics applications where synchronization errors below 50 microseconds are mandatory.

Open-source frameworks like ROS2 (Robot Operating System) have standardized motor control interfaces. A typical deployment might involve a Raspberry Pi running ROS2 nodes that publish velocity commands via CAN bus to motor controllers. Below is a simplified code snippet illustrating topic-based communication:

import rclpy

from rclpy.node import Node

from can_msgs.msg import MotorCommand

class MotorController(Node):

def __init__(self):

super().__init__('motor_controller')

self.subscription = self.create_subscription(

MotorCommand,

'target_velocity',

self.listener_callback,

10)

def listener_callback(self, msg):

# Convert RPM to PWM duty cycle

duty_cycle = msg.rpm * 0.025

apply_pwm_to_motor(duty_cycle)

Challenges and Future Directions

Despite progress, thermal management remains a persistent hurdle. High-density motor controllers in humanoid robots generate up to 40W/cm², necessitating advanced cooling solutions like vapor chambers or piezoelectric fans. Researchers at MIT recently demonstrated a phase-change material (PCM) heat sink that reduces peak temperatures by 18°C in constrained spaces.

Looking ahead, the integration of quantum computing principles into motor control algorithms presents intriguing possibilities. Quantum annealing techniques could solve torque distribution problems across multi-joint robotic systems in polynomial time—a task that currently requires heuristic approaches. Meanwhile, the adoption of gallium nitride (GaN) transistors promises to push PWM frequencies beyond 1 MHz, further minimizing torque ripple.

In , robotic motor control technology continues to redefine the boundaries of automation. From neural-adaptive control schemes to quantum-inspired optimization, these advancements not only enhance robotic dexterity but also pave the way for applications we have yet to imagine. As hardware and algorithms co-evolve, the next decade will likely witness motor control systems achieving biological-level fluidity in motion.