The development of hexapod robots – six-legged machines inspired by insects and arachnids – represents a frontier in robotics research. While these systems offer advantages in terrain adaptability and load distribution, engineers face multifaceted technical hurdles during design and implementation. This article explores the core challenges shaping hexapod robotics and examines emerging solutions pushing the boundaries of mechanical and computational innovation.

1. Kinematic Complexity and Gait Optimization

Coordinating six limbs demands sophisticated motion algorithms exceeding traditional bipedal or quadrupedal systems. Each leg operates as an independent kinematic chain with 3-4 degrees of freedom, requiring real-time synchronization across 18-24 actuators. Researchers at Carnegie Mellon University recently demonstrated that improper phase sequencing can increase energy consumption by 40% while reducing stability margins by 60%.

Current solutions employ hybrid control architectures combining:

# Simplified gait pattern generator

def generate_wave_gait(phase_offset):

leg_sequence = [(i + phase_offset) % 6 for i in range(6)]

return optimize_torque_distribution(leg_sequence)

Such code frameworks help balance computational load while maintaining adaptive walking patterns. However, dynamic terrain responses still challenge even advanced reinforcement learning models, particularly when handling sudden surface transitions.

2. Power Management and Structural Efficiency

Hexapods inherently carry higher mass penalties than wheeled platforms. MIT's Biomimetic Robotics Lab found their 22kg prototype consumed 500W during continuous operation – equivalent to powering 10 laptop computers. This stems from simultaneous actuator demands and structural reinforcement needs.

Innovative approaches include:

- Bio-inspired composite materials reducing frame weight by 30-45%

- Selective joint locking mechanisms preserving energy during static phases

- Regenerative braking systems recovering up to 15% of motion energy

Field tests at volcanic sites demonstrated that optimized power systems extended operational durations from 2.1 to 5.7 hours between charges – a critical improvement for search/rescue applications.

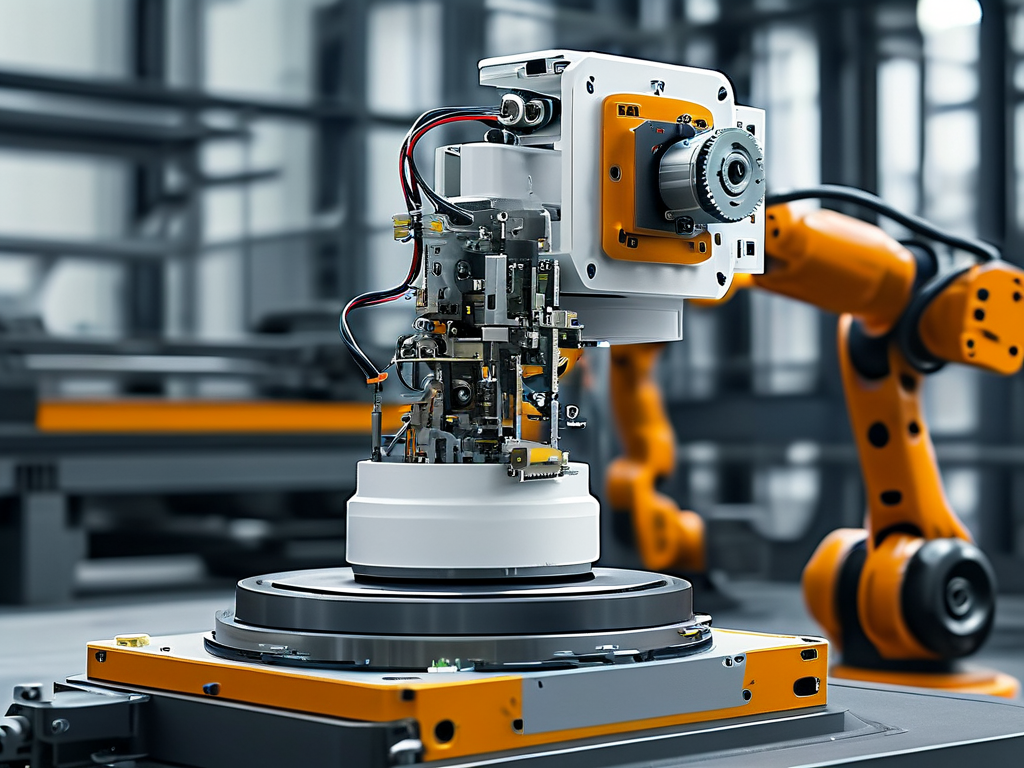

3. Sensor Fusion and Environmental Interaction

Effective navigation requires integrating multiple perception modalities. A hexapod deployed in disaster zones must process LiDAR, thermal imaging, and tactile feedback simultaneously while avoiding computational bottlenecks. The University of Tokyo's HECTOR project achieved 83ms response latency through FPGA-accelerated sensor fusion, but cost constraints limit commercial scalability.

Emerging solutions leverage:

- Neuromorphic cameras reducing data throughput by 70%

- Distributed processing units at each limb node

- Self-calibrating pressure sensors compensating for leg wear

4. Fault Tolerance and Maintenance Complexity

With 150+ moving parts in typical designs, failure probability increases exponentially. DARPA's Legged Squad Support System (LS3) program revealed that dust infiltration caused 78% of field failures during desert trials. Modular designs now allow rapid joint replacement, while predictive maintenance algorithms analyze motor currents to anticipate bearing failures 20-30 hours in advance.

Future Directions

Recent advancements in liquid-cooled actuators and quantum-dot-based strain sensors hint at next-generation improvements. As artificial muscle technologies mature, future hexapods may achieve insect-like efficiency while maintaining payload capacities exceeding 150kg. The convergence of these innovations promises to transform applications from precision agriculture to extraterrestrial exploration, provided engineers can sustainably address the core technical challenges outlined here.