In the rapidly evolving landscape of technology, embedded platform development remains a cornerstone for innovations in IoT, automotive systems, and industrial automation. Crafting a robust embedded platform requires a blend of hardware-software synergy, meticulous planning, and adaptive execution. This article explores actionable strategies to streamline development workflows, address common challenges, and deliver scalable solutions.

Balancing Hardware and Software Requirements

A critical first step in embedded platform development is defining hardware specifications that align with software objectives. For resource-constrained devices, selecting microcontrollers or System-on-Chip (SoC) components with optimal power consumption and processing capabilities is paramount. Developers often leverage ARM Cortex-M series or RISC-V architectures for their flexibility and efficiency. Concurrently, software teams must prioritize real-time operating systems (RTOS) or lightweight Linux distributions to ensure seamless integration.

Consider a smart sensor node designed for agricultural monitoring. The hardware might integrate a low-power STM32 microcontroller paired with LoRaWAN connectivity, while the firmware employs FreeRTOS to manage sensor data collection and transmission tasks. This harmony between hardware and software minimizes latency and maximizes battery life.

Toolchain Optimization for Faster Iteration

Modern embedded development relies heavily on toolchains that support cross-compilation, debugging, and version control. Platforms like PlatformIO or ARM Keil provide integrated environments for code development, while JTAG probes and logic analyzers assist in hardware debugging. Automating build processes with CI/CD pipelines—using tools like Jenkins or GitHub Actions—reduces manual errors and accelerates deployment cycles.

For example, a team developing a medical wearable might use PlatformIO to manage dependencies for Bluetooth Low Energy (BLE) libraries, alongside automated unit testing frameworks to validate firmware updates before OTA deployment.

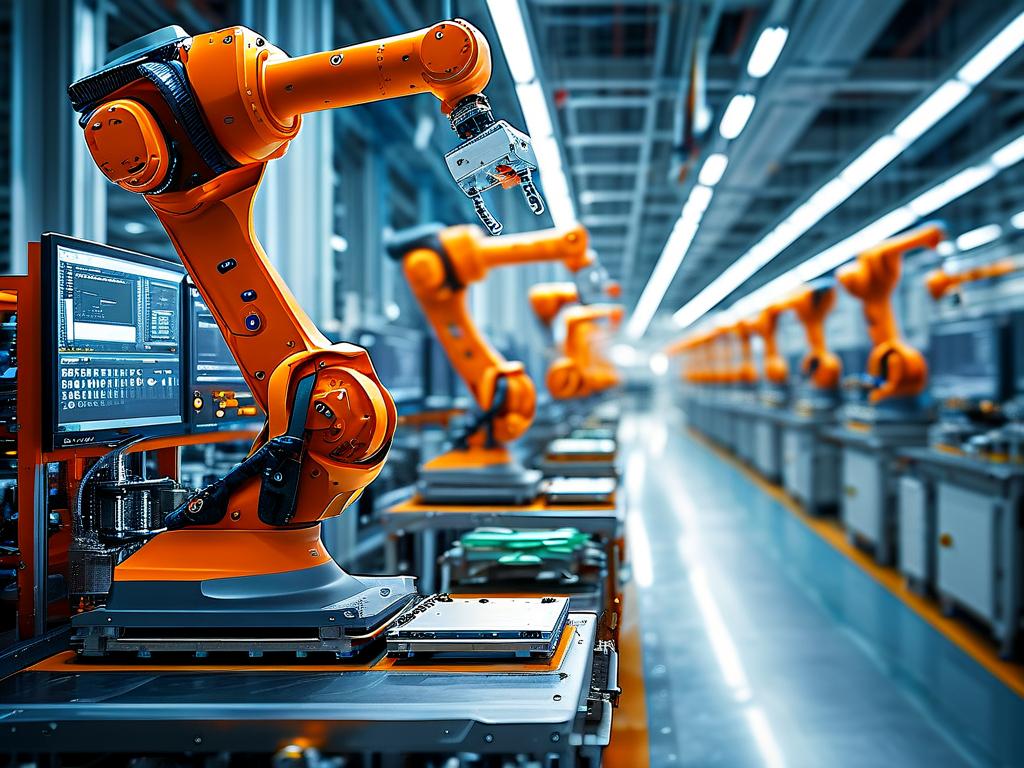

Addressing Security and Scalability

Embedded systems are increasingly targeted by cyber threats, making security a non-negotiable aspect of development. Implementing hardware-based secure bootloaders, encrypted communication protocols (e.g., TLS/SSL), and regular firmware signing are essential practices. Additionally, designing modular architectures allows platforms to scale. A modular approach enables developers to add or remove features—such as machine learning inference engines or additional sensor interfaces—without overhauling the entire system.

Take an industrial automation controller: Using a modular FPGA-based design allows engineers to reconfigure logic gates for new production line requirements, while integrating Trusted Platform Module (TPM) chips ensures data integrity across networked devices.

Case Study: Automotive Telematics System

A practical illustration of these principles is seen in automotive telematics. A leading EV manufacturer recently migrated from a monolithic embedded platform to a microservices-oriented architecture. By decoupling navigation, battery management, and diagnostics into containerized modules, the team reduced firmware update times by 40% and improved fault isolation. Hardware upgrades included a shift to automotive-grade SoCs with built-in hardware security modules (HSM), ensuring compliance with ISO 21434 standards.

Embedded platform development demands a holistic approach that balances technical precision with adaptability. By prioritizing hardware-software co-design, optimizing toolchains, and embedding security at every layer, developers can create platforms that not only meet current demands but also evolve with future challenges. As edge computing and AI-driven applications grow, these strategies will remain pivotal in shaping the next generation of embedded systems.

// Sample code snippet: GPIO initialization for sensor interfacing

#include "stm32f4xx.h"

void configureGPIO() {

RCC->AHB1ENR |= RCC_AHB1ENR_GPIOAEN; // Enable GPIOA clock

GPIOA->MODER |= GPIO_MODER_MODE5_0; // Set PA5 as output

GPIOA->OTYPER &= ~GPIO_OTYPER_OT5; // Push-pull mode

GPIOA->OSPEEDR |= GPIO_OSPEEDER_OSPEED5; // High speed

}