The robotics industry is experiencing unprecedented expansion, driven by advancements in artificial intelligence, sensor technologies, and automation demand. According to recent market analyses, the global robotics market is projected to exceed $210 billion by 2028, with compound annual growth rates hovering around 17%. This surge spans multiple sectors, including manufacturing, healthcare, agriculture, and logistics, reshaping traditional workflows and redefining human-machine collaboration.

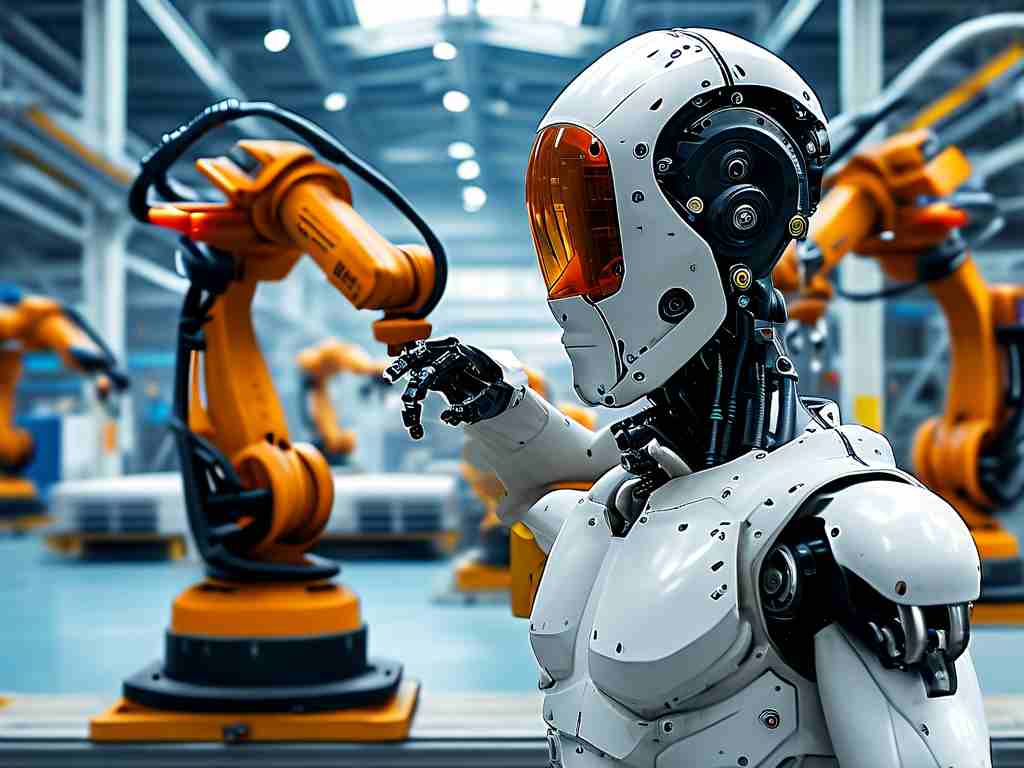

Manufacturing Dominance and New Frontiers

Industrial robots remain the backbone of the sector, accounting for 55% of current market revenue. Automotive assembly lines continue to leverage high-payload articulated robots for precision tasks, while electronics manufacturers increasingly adopt collaborative robots (cobots) for circuit board assembly. A notable shift emerges in small-to-medium enterprises adopting modular robotic solutions, reducing implementation costs by 40% compared to legacy systems.

Beyond factory floors, agricultural robotics is witnessing 23% year-over-year growth. Autonomous tractors equipped with LiDAR and multispectral imaging now operate across 15% of U.S. farmland, optimizing irrigation and pesticide deployment. In Japan, strawberry-picking robots utilizing tactile feedback sensors have reduced harvest losses by 18%, addressing labor shortages in aging rural communities.

Healthcare’s Robotic Renaissance

Medical robotics has transitioned from experimental to essential, particularly in surgical applications. The da Vinci Surgical System, now present in over 5,000 hospitals worldwide, has demonstrated 30% faster patient recovery times in prostatectomies compared to traditional methods. Rehabilitation robotics is gaining traction, with exoskeleton shipments increasing 140% since 2021 – driven partly by neurological disorder therapies and military medical applications.

Diagnostic robotics represents an emerging niche. Boston-based startups are deploying AI-guided robotic phlebotomy systems that achieve 99% vein detection accuracy, potentially reducing procedure times by half. However, regulatory hurdles persist, with only 12% of proposed medical robotic systems receiving FDA clearance within proposed timelines.

Technical Bottlenecks and Ethical Debates

Despite progress, persistent challenges constrain widespread adoption. Power efficiency remains critical – industrial robots consume 38% more energy than equivalent human-operated systems over five-year periods. Researchers at ETH Zurich recently unveiled a hydraulic-actuated robotic arm that cuts energy use by 53%, though commercialization timelines remain uncertain.

Workforce displacement concerns continue sparking policy discussions. The International Federation of Robotics estimates 20 million manufacturing jobs could be automated by 2030, while only 14 million new tech-related positions may emerge. South Korea’s proposed “Robot Tax” – a 2% levy on companies replacing human workers with automation – has ignited global debates about balancing innovation and employment stability.

Regional Development Disparities

Asia-Pacific dominates robotics adoption, responsible for 67% of global installations. China’s “Made in 2025” initiative has propelled its robotics density (robots per 10,000 workers) from 49 in 2016 to 246 in 2023. Contrastingly, African nations collectively account for less than 0.3% of industrial robot deployments, highlighting infrastructure and investment gaps.

Europe emphasizes ethical frameworks, with the EU’s AI Act mandating real-time human oversight for autonomous systems in critical infrastructure. Meanwhile, North America sees venture capital flooding into service robotics – hotel cleaning bots and retail inventory bots secured $2.3 billion in funding during Q1 2024 alone.

Future Trajectories

Three key trends are shaping the industry’s roadmap:

- Swarm robotics for large-scale coordination (e.g., disaster response drone fleets)

- Neuromorphic computing enabling energy-efficient decision-making

- 5G-enabled edge computing reducing cloud dependency

Material science breakthroughs may soon yield self-healing polymer actuators, while quantum computing could revolutionize motion planning algorithms. As the industry evolves, balancing technological potential with societal impact will determine whether robotics becomes humanity’s greatest tool or its most disruptive force.