The integration of robotics into workplaces has transformed industries by enhancing efficiency, reducing operational costs, and minimizing human error. From manufacturing to healthcare, robots are now pivotal in driving innovation. This article explores key advancements in workplace robotics, their applications, and the challenges they address.

Core Technologies Shaping Modern Robotics

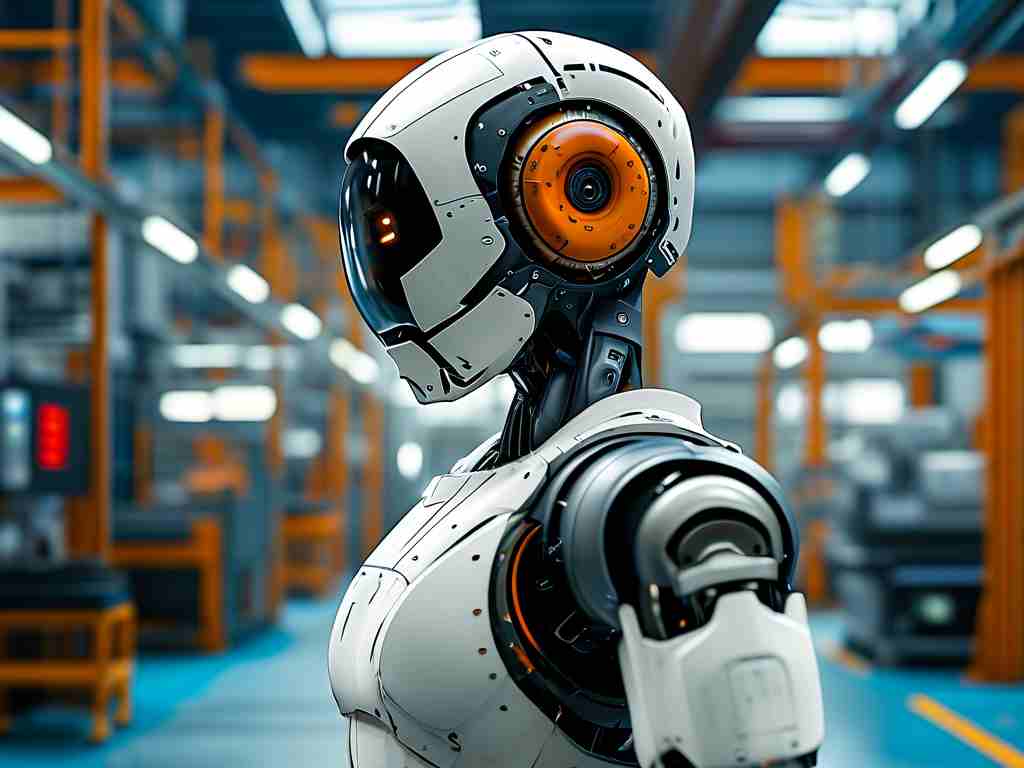

At the heart of workplace robotics lie several cutting-edge technologies. Artificial intelligence (AI) enables robots to learn from data, adapt to dynamic environments, and make decisions autonomously. Machine learning algorithms, for instance, allow robots to optimize assembly line processes by analyzing production patterns. Computer vision systems empower robots to recognize objects, navigate spaces, and perform tasks like quality inspection with precision.

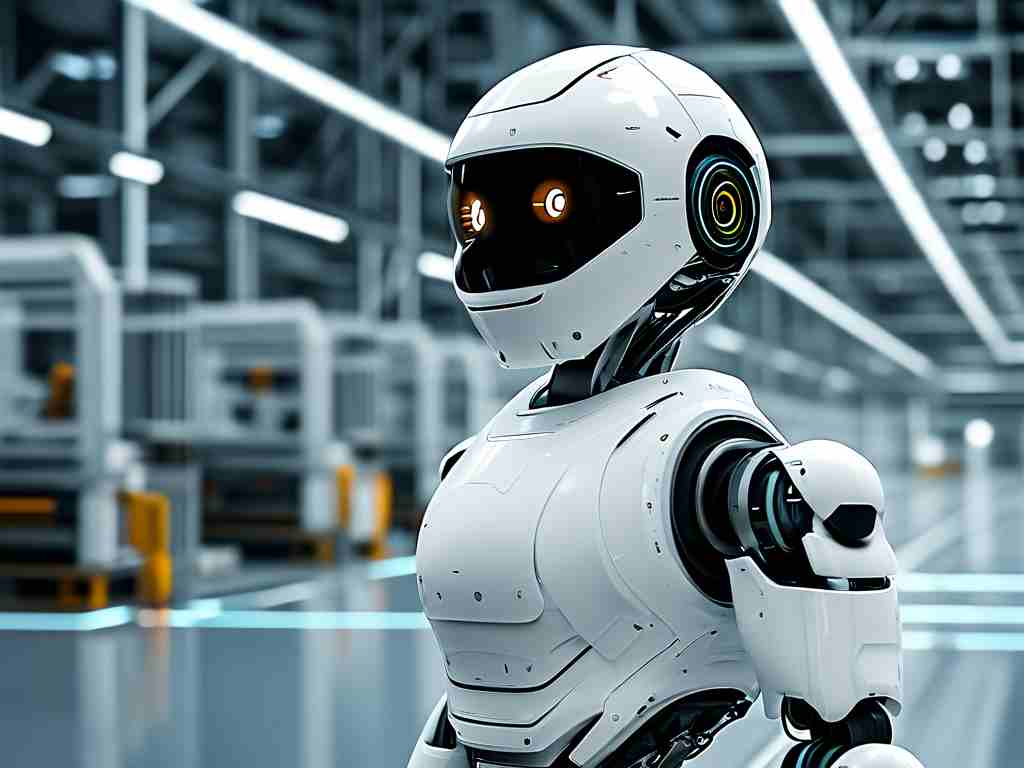

Collaborative robots, or "cobots," represent another breakthrough. Unlike traditional industrial robots that operate in isolated zones, cobots work alongside humans. Equipped with force-sensitive sensors, they can detect human presence and adjust their movements to prevent accidents. This technology is particularly valuable in sectors like automotive manufacturing, where humans and machines assemble components together.

Applications Across Industries

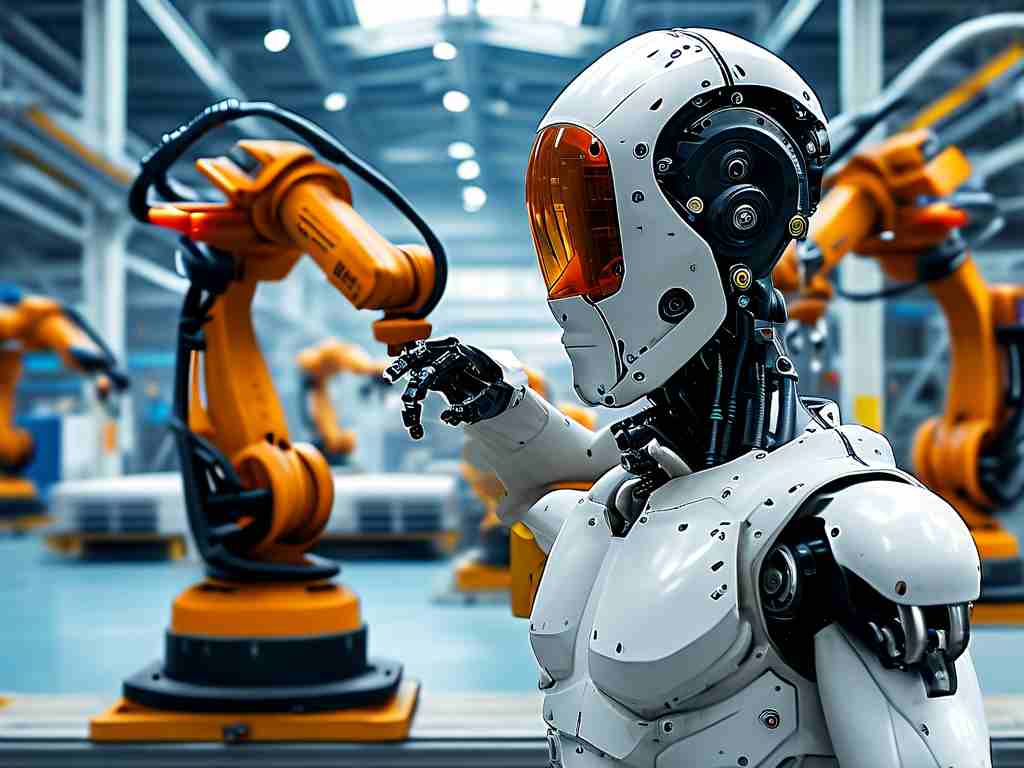

In manufacturing, robots handle repetitive tasks such as welding, painting, and packaging. Companies like Tesla use robotic arms to assemble electric vehicles, achieving faster production cycles. Meanwhile, logistics giants like Amazon deploy autonomous mobile robots (AMRs) in warehouses to transport goods, reducing reliance on manual labor.

Healthcare has also embraced robotics. Surgical robots like the da Vinci System assist surgeons in performing minimally invasive procedures with enhanced accuracy. Rehabilitation robots aid patients in recovering motor functions, while disinfection robots use ultraviolet light to sanitize hospitals, a practice accelerated by the COVID-19 pandemic.

The agricultural sector benefits from autonomous tractors and harvesters. These machines leverage GPS and AI to plant seeds, monitor crop health, and harvest produce, addressing labor shortages and improving yield. Similarly, drones equipped with thermal cameras survey farmland, identifying irrigation issues or pest infestations early.

Challenges and Ethical Considerations

Despite their advantages, workplace robots face technical and societal hurdles. High upfront costs remain a barrier for small businesses, though prices are gradually decreasing. Maintenance complexity also poses challenges, as malfunctioning robots require specialized technicians, leading to downtime.

Ethical concerns around job displacement persist. While robots eliminate mundane tasks, they also shift workforce demands toward roles requiring technical skills. Governments and organizations must invest in reskilling programs to prepare employees for this transition. Data privacy is another issue, as AI-driven robots collect vast amounts of operational data, raising questions about ownership and security.

Future Outlook

The future of workplace robotics hinges on interoperability and sustainability. Developers are focusing on creating universal software platforms that allow robots from different manufacturers to communicate seamlessly. Energy-efficient designs are also gaining traction, with solar-powered robots emerging in construction and mining.

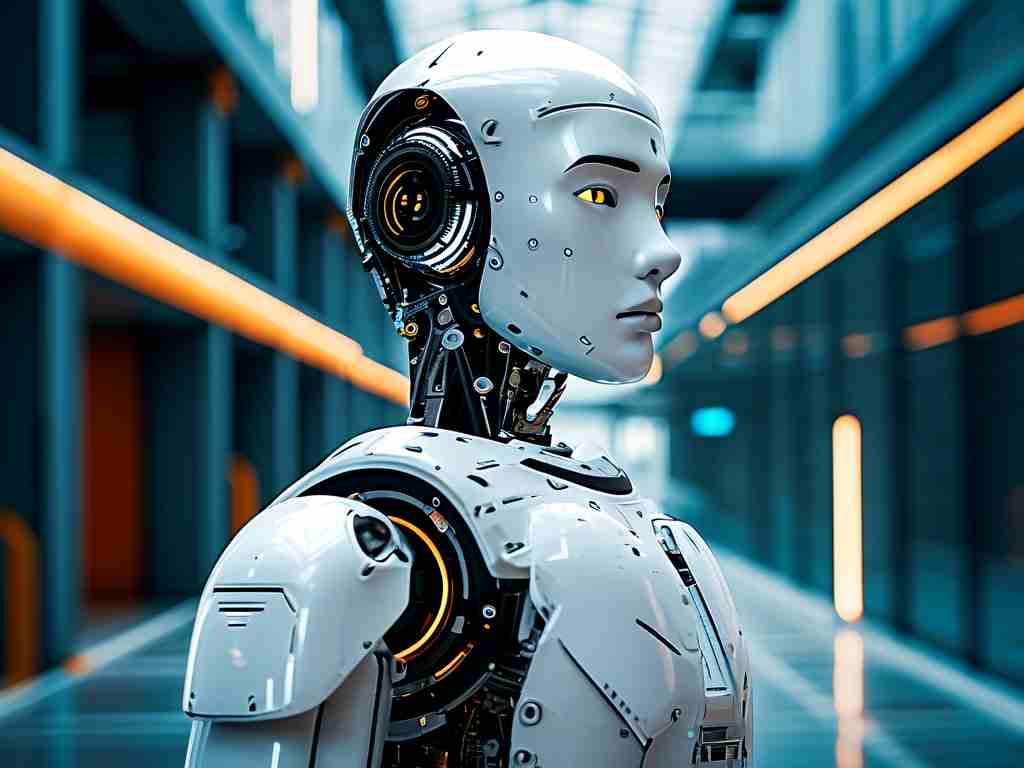

Human-robot collaboration will deepen, with AI becoming more intuitive. For example, robots might soon interpret verbal instructions or gestures, making them accessible to non-technical users. Advances in quantum computing could further enhance robotic decision-making speeds, unlocking new possibilities in real-time problem-solving.

In , workplace robotics is not just a trend but a cornerstone of modern industry. By addressing current limitations and fostering ethical adoption, businesses can harness these technologies to build resilient, innovative operations.