The global robotics industry has entered an unprecedented phase of expansion, driven by technological convergence and cross-sector adoption. Valued at $43.8 billion in 2023, this sector is projected to surpass $135 billion by 2030, according to independent market research firm TechAnalytics Pro. This growth trajectory stems not from isolated advancements but from the symbiotic evolution of artificial intelligence, material science, and edge computing.

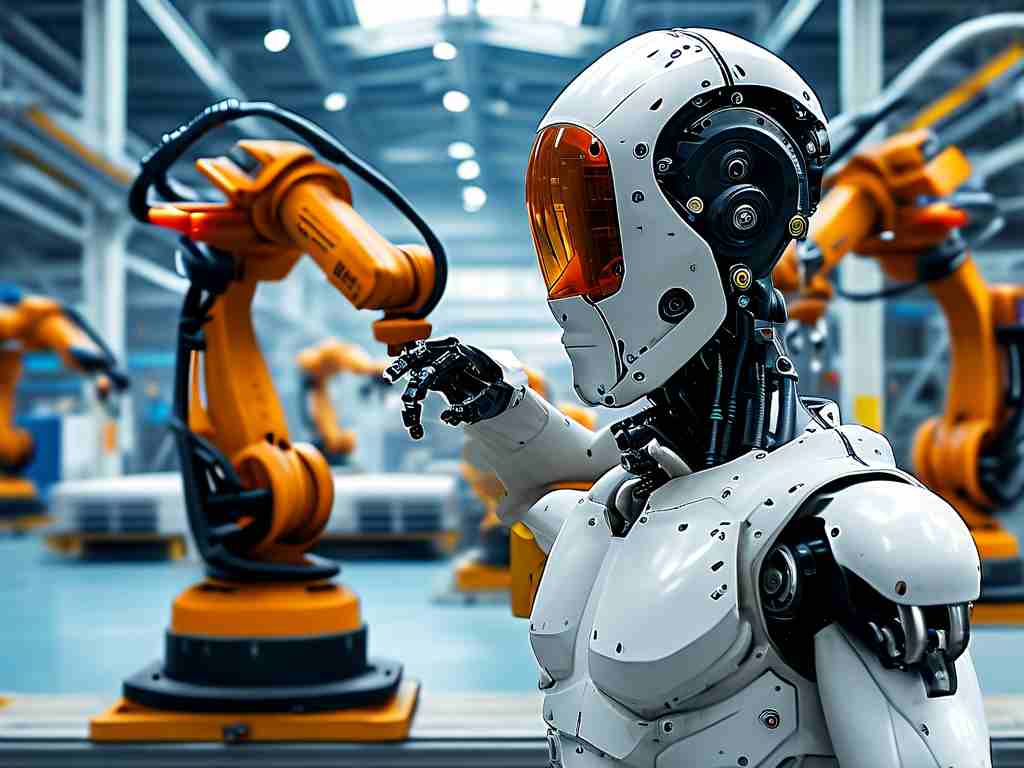

Three fundamental forces are reshaping commercial robotics applications. First, collaborative robots (cobots) now account for 38% of industrial automation installations, as verified by the International Federation of Robotics' 2024 report. These adaptive systems work alongside human operators in automotive plants and electronics assembly lines, combining precision with contextual awareness. Second, medical robotics has achieved a 22% compound annual growth rate since 2020, with surgical assistance devices like the NeuroArm3 demonstrating sub-millimeter accuracy in complex procedures. Third, autonomous mobile robots (AMRs) have revolutionized logistics, reducing warehouse operational costs by up to 40% according to supply chain analysts at LogiTech Insights.

Emerging markets demonstrate unique adoption patterns. Southeast Asian manufacturing hubs now deploy robotics solutions at triple the rate observed in 2019, while Scandinavian countries lead in service robotics for elderly care. The agricultural sector presents unexpected growth potential – automated harvesting systems increased crop yields by 17% in California's Central Valley trials conducted by AgriBot Systems Inc.

Technical barriers persist despite these advancements. Energy efficiency remains a critical challenge, with current generation humanoid robots requiring 2.4kW/h for basic mobility functions. Researchers at MIT's Biomechatronics Lab recently unveiled a biomimetic actuator system that reduces power consumption by 62%, though commercial availability remains 3-5 years distant. Sensor fusion complexity also limits real-world deployment – while laboratory prototypes achieve 99.8% object recognition accuracy, field performance in dynamic environments rarely exceeds 87%.

Regulatory frameworks struggle to match the pace of innovation. The European Union's proposed Artificial Intelligence Act imposes stringent requirements for autonomous decision-making systems, potentially delaying deployment of AI-driven inspection robots. Conversely, Japan's revised Robot Safety Guidelines 2025 adopt a permissive approach, emphasizing post-market surveillance over pre-approval restrictions. This regulatory divergence creates compliance challenges for multinational corporations developing standardized robotic platforms.

Workforce transformation represents both opportunity and disruption. The World Economic Forum estimates that robotics integration will create 12 million new tech maintenance and programming roles by 2028, while rendering 7% of current manufacturing positions obsolete. Vocational training initiatives like Germany's RobotReady program demonstrate successful transitions, retraining 84% of automotive workers for robotics supervision roles within 18-month cycles.

Ethical considerations are gaining prominence in development roadmaps. A 2024 industry survey by RoboEthics International revealed that 73% of robotics engineers prioritize explainable AI systems, particularly in healthcare applications. This shift follows incidents like the 2023 Seoul Surgical Bot Malfunction, where an unexplained navigation error during a routine procedure prompted renewed focus on decision transparency.

Looking forward, three key developments will define the next evolutionary phase. Neuromorphic computing architectures promise to enhance real-time processing capabilities, with Intel's Loihi 3 chip demonstrating 18x faster pattern recognition than conventional GPUs in controlled tests. Material science breakthroughs in self-healing polymers could extend robotic component lifespans by 400%, dramatically reducing maintenance costs. Perhaps most crucially, the emergence of quantum machine learning algorithms may solve current path-planning limitations, enabling truly autonomous navigation in unstructured environments.

The robotics revolution is not coming – it's already here. From micro-scale nanobots clearing arterial blockages to 20-ton autonomous mining vehicles reshaping resource extraction, intelligent machines are redefining productivity parameters across industries. Success in this new paradigm demands not just technical proficiency but strategic foresight, ethical awareness, and adaptive workforce planning. Those who master this trifecta will lead the next chapter of industrial evolution.