Haptic sensing technology, which enables machines to perceive and interact with their environment through touch, has revolutionized robotics. By mimicking the human sense of touch, robots equipped with haptic systems can perform delicate tasks, navigate complex environments, and collaborate safely with humans. This article explores the principles, advancements, and transformative applications of haptic sensing in modern robotics.

Principles of Haptic Sensing

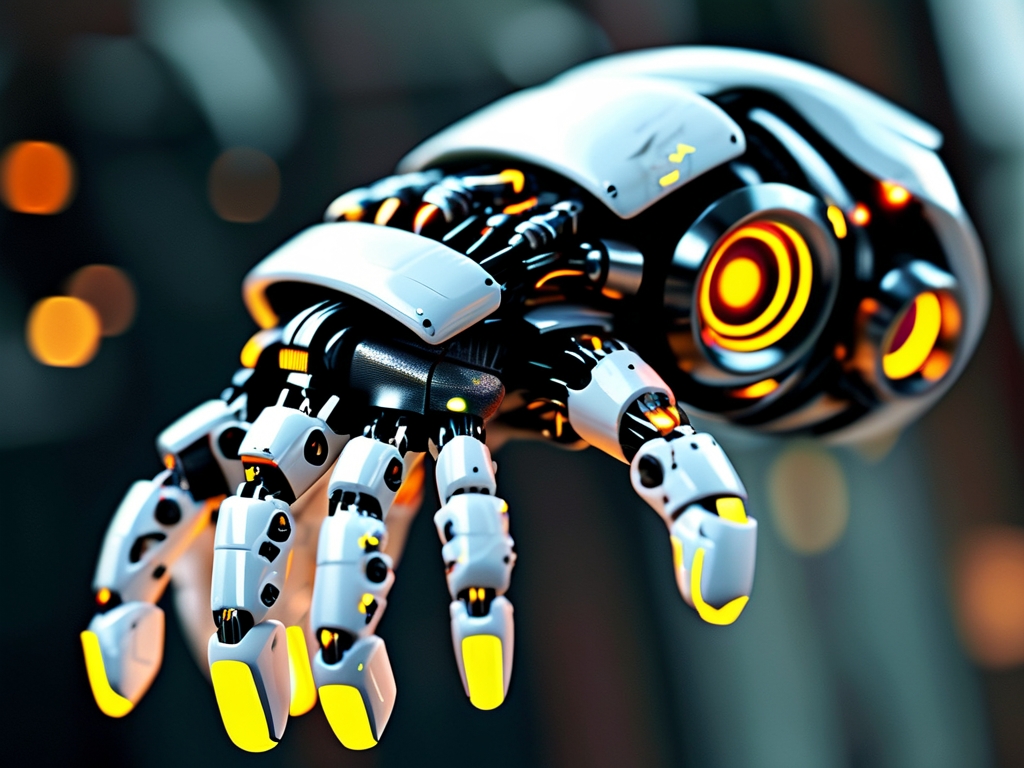

At its core, haptic sensing relies on sensors that detect physical interactions such as pressure, vibration, temperature, and texture. These sensors convert mechanical stimuli into electrical signals, processed by algorithms to guide robotic actions. Key technologies include:

- Force-Sensing Resistors (FSRs): Measure pressure distribution during object manipulation.

- Piezoelectric Sensors: Detect dynamic forces like vibrations.

- Capacitive and Optical Sensors: Capture subtle texture or shape changes.

- Artificial Skin: Flexible, multi-layered materials embedding thousands of micro-sensors for nuanced tactile feedback.

Historical Milestones

The concept of robotic touch dates to the 1980s, with early experiments using basic pressure sensors in industrial arms. Breakthroughs emerged in the 2000s, driven by advancements in materials science and machine learning. Notable milestones include:

- 2008: MIT’s CSAIL developed a gripper with tactile feedback for fragile object handling.

- 2015: Stanford University introduced “BioTac,” a sensor mimicking human fingertip sensitivity.

- 2020: Shadow Robot Company integrated haptic feedback into surgical robots for real-time tissue response analysis.

Applications Across Industries

-

Healthcare and Surgery

Haptic-enabled surgical robots, such as the da Vinci Surgical System, allow surgeons to “feel” tissues remotely, enhancing precision in minimally invasive procedures. Prosthetics with tactile feedback restore sensory capabilities for amputees, improving mobility and quality of life. -

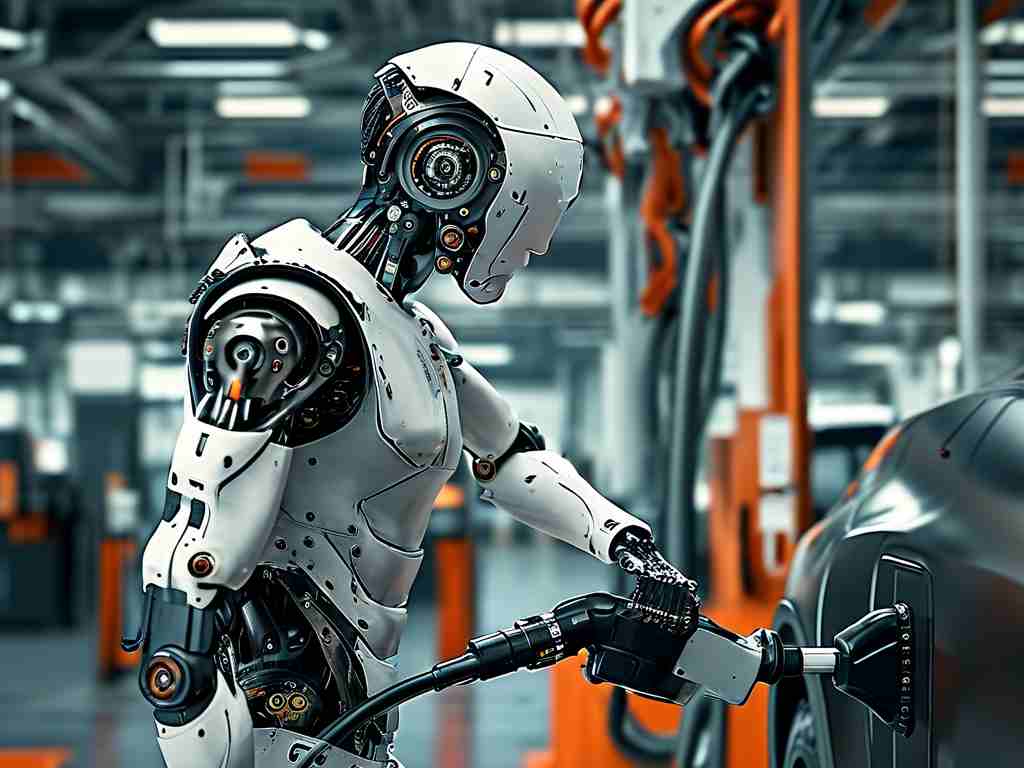

Industrial Automation

In manufacturing, robots with tactile sensors assemble electronics, handle fragile materials, and perform quality checks. For example, BMW uses haptic-guided robots to install car interiors without damaging components. -

Agriculture and Food Processing

Robotic harvesters equipped with tactile feedback identify ripe produce and adjust grip strength to avoid bruising. Similarly, food-packaging robots detect texture changes to sort items by freshness. -

Search and Rescue

Haptic sensors enable rescue robots to navigate debris-filled environments. Drones with tactile arms, like those tested by NASA, assess structural stability in disaster zones by “feeling” surfaces. -

Consumer Robotics

From vacuum cleaners avoiding obstacles to companion robots offering gentle physical interactions, haptic tech enhances user experience and safety in everyday devices.

Challenges and Limitations

Despite progress, hurdles remain:

- Sensor Durability: Repeated mechanical stress degrades sensor accuracy.

- Data Processing Complexity: High-resolution tactile data requires immense computational power.

- Cost: Advanced haptic systems remain prohibitively expensive for small-scale applications.

- Human-Machine Interface Gaps: Achieving true human-like touch sensitivity is still elusive.

Future Directions

Researchers are addressing these challenges through:

- Self-Healing Materials: Sensors that repair minor damages autonomously.

- Edge Computing: On-device AI to process tactile data in real time.

- Neuromorphic Engineering: Chips mimicking the human nervous system for faster response.

- Collaborative Robotics (Cobots): Systems where humans and robots share tactile feedback for seamless teamwork.

Ethical and Societal Implications

As haptic robots enter sensitive fields like healthcare and elderly care, ethical questions arise:

- Privacy: Tactile data could reveal personal information (e.g., biometrics).

- Job Displacement: Automation in manufacturing and services may disrupt labor markets.

- Safety Standards: Ensuring robots cannot harm humans during physical interactions.

Haptic sensing technology is redefining the boundaries of robotics, enabling machines to interact with the world in once unimaginable ways. From life-saving medical applications to sustainable agriculture, its impact spans industries. While challenges persist, ongoing innovations promise a future where robots not only see and hear but truly “feel” their environment—ushering in an era of empathetic, intelligent machines.

References

- Nature Robotics (2023): “Advances in Artificial Skin Technologies.”

- IEEE Transactions on Haptics: “Machine Learning for Tactile Data Interpretation.”

- MIT Technology Review: “The Next Frontier in Surgical Robotics.”