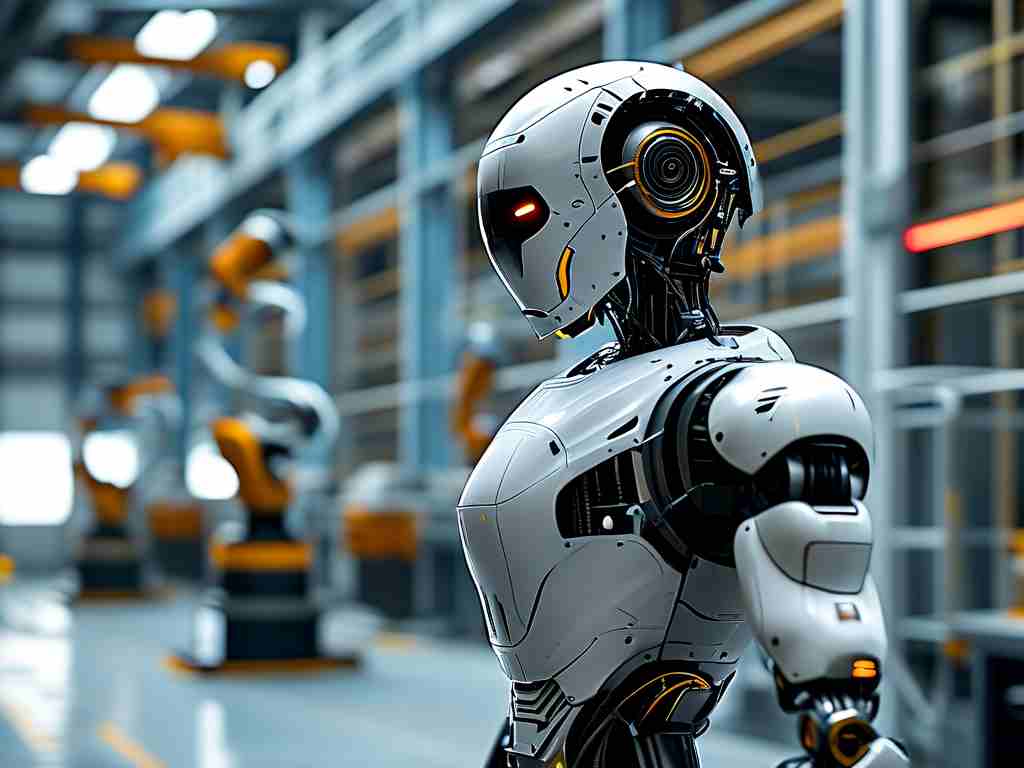

In the rapidly evolving landscape of modern technology, universal technical robots have emerged as a transformative force across industries. These advanced machines are designed to perform a wide range of tasks with minimal human intervention, leveraging cutting-edge technologies such as artificial intelligence (AI), machine learning, and modular hardware systems. Unlike specialized robots built for singular purposes, universal technical robots prioritize adaptability, making them indispensable in environments requiring flexibility and precision.

At their core, universal technical robots rely on adaptive algorithms that enable them to learn from real-time data and adjust their operations dynamically. For example, in manufacturing settings, these robots can switch between assembling electronic components and packaging finished products without manual reprogramming. This capability is powered by AI frameworks that analyze workflow patterns and optimize task execution. A snippet of code illustrating this adaptability might include:

def task_optimizer(sensor_data):

if sensor_data['task'] == 'assembly':

adjust_gripper_pressure(level=5)

elif sensor_data['task'] == 'packaging':

activate_conveyor_belt(speed=2)

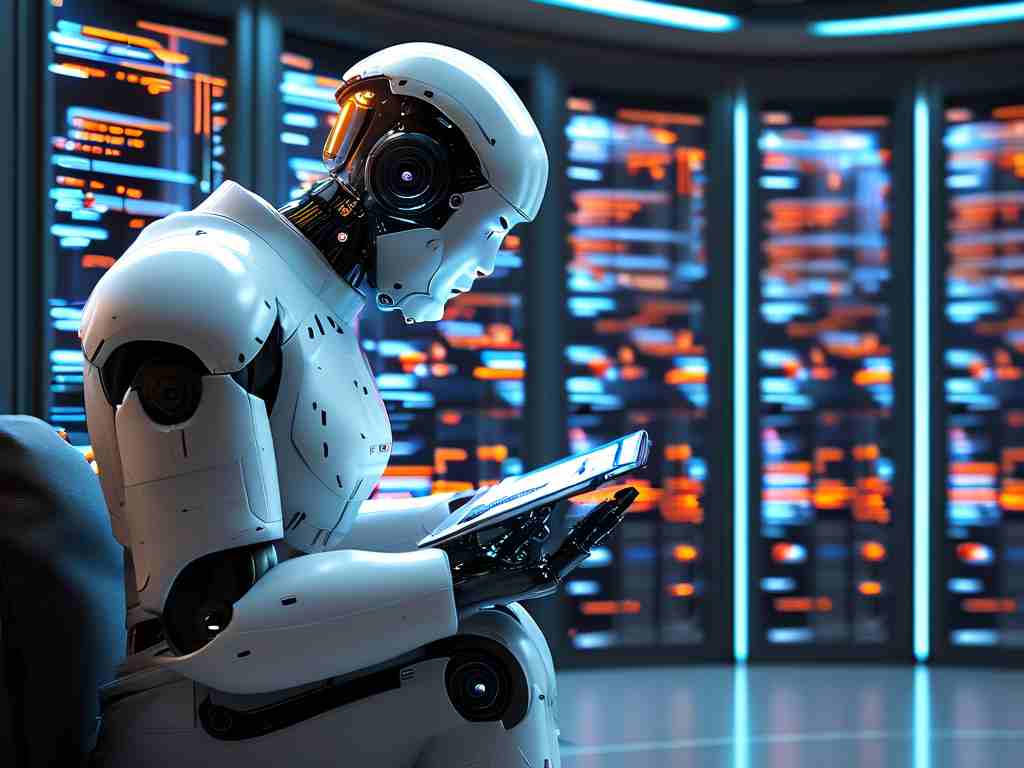

The versatility of universal technical robots extends beyond industrial applications. In healthcare, they assist in surgeries by integrating with imaging systems to provide real-time feedback to surgeons. Agricultural sectors deploy them for precision farming, where they monitor crop health and administer targeted treatments. This cross-industry relevance underscores their role as multi-functional tools capable of addressing diverse challenges.

A key advantage of these robots lies in their modular design. Components such as grippers, sensors, and mobility units can be swapped or upgraded based on task requirements. For instance, a robot equipped with thermal sensors for warehouse inventory management can be reconfigured with high-resolution cameras for quality inspection in food processing. This modularity reduces long-term costs and extends the robot’s operational lifespan.

However, the development of universal technical robots is not without challenges. Ensuring seamless interoperability between software and hardware remains a technical hurdle. Engineers must balance computational power with energy efficiency, especially for robots deployed in remote or resource-limited environments. Additionally, ethical considerations around job displacement and data security require ongoing dialogue among policymakers, businesses, and technologists.

Looking ahead, advancements in quantum computing and 5G connectivity are poised to enhance the capabilities of universal technical robots. Faster data processing and low-latency communication will enable real-time decision-making in complex scenarios, such as disaster response or autonomous transportation. Collaborative robots (cobots) working alongside humans will also become more intuitive, using natural language processing to understand verbal instructions.

In , universal technical robots represent a convergence of innovation and practicality. By bridging the gap between specialized automation and human ingenuity, they are redefining what machines can achieve. As industries continue to adopt these solutions, the focus will shift from mere automation to creating synergies that amplify productivity, safety, and creativity.