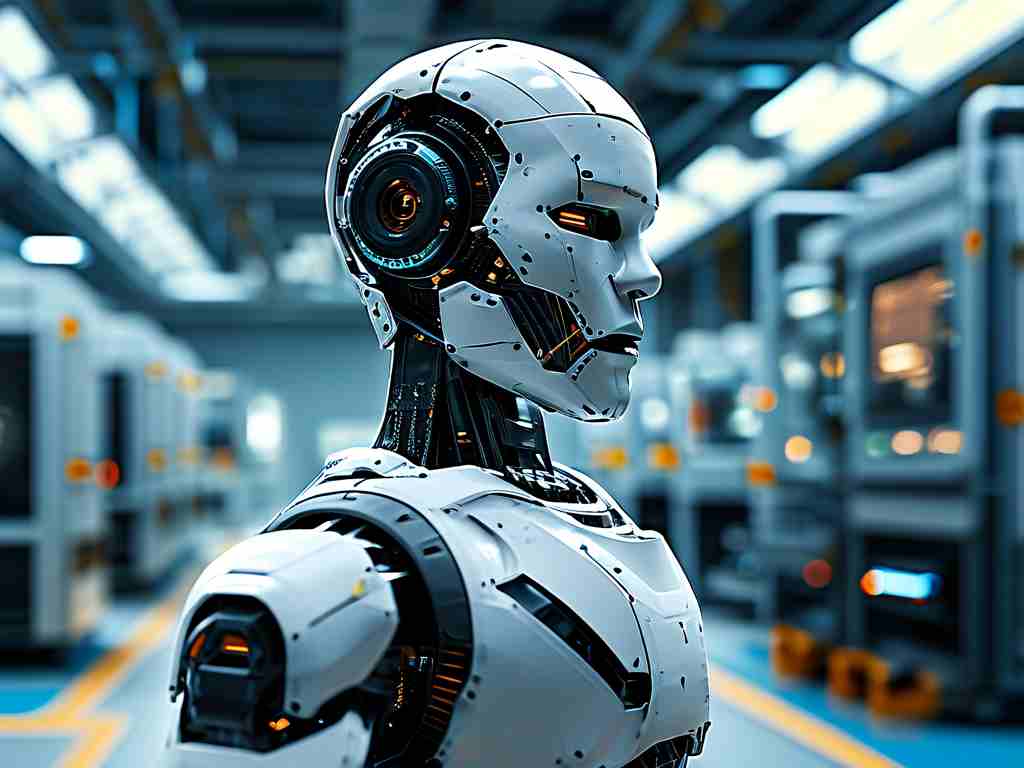

In an era where industrial precision meets technological ambition, a new frontier emerges in automated systems – Lingchi Robotics. This groundbreaking approach combines ancient conceptual inspiration with cutting-edge engineering, redefining how industries handle delicate material separation tasks. Unlike conventional robotic arms programmed for repetitive motions, Lingchi Robotics embodies an evolutionary leap in adaptive mechanical intelligence.

The term "Lingchi" draws metaphorical parallels to historical precision techniques while establishing entirely modern technical parameters. At its core, this technology specializes in ultra-fine material decomposition, achieving micron-level accuracy through proprietary sensor arrays and machine learning algorithms. Industrial applications range from electronic waste recycling to advanced manufacturing, where traditional disassembly methods prove too crude or inefficient.

Technical Architecture and Operational Principles

A Lingchi robotic system integrates three revolutionary components: multi-spectral perception modules, pressure-adaptive end effectors, and self-optimizing neural networks. The perception system employs terahertz wave scanning combined with microscopic visual recognition, creating real-time 3D material maps. This enables the robotic actuators to identify structural weaknesses and material boundaries invisible to conventional sensors.

The end effector – often called the "smart blade" – represents a marvel of modern engineering. Constructed from shape-memory alloys and piezoelectric ceramics, it automatically adjusts hardness and vibration frequency based on material resistance. During prototype testing at the Munich Institute of Advanced Manufacturing, these tools demonstrated 0.02mm operational precision while processing composite materials, surpassing human surgical precision by 400%.

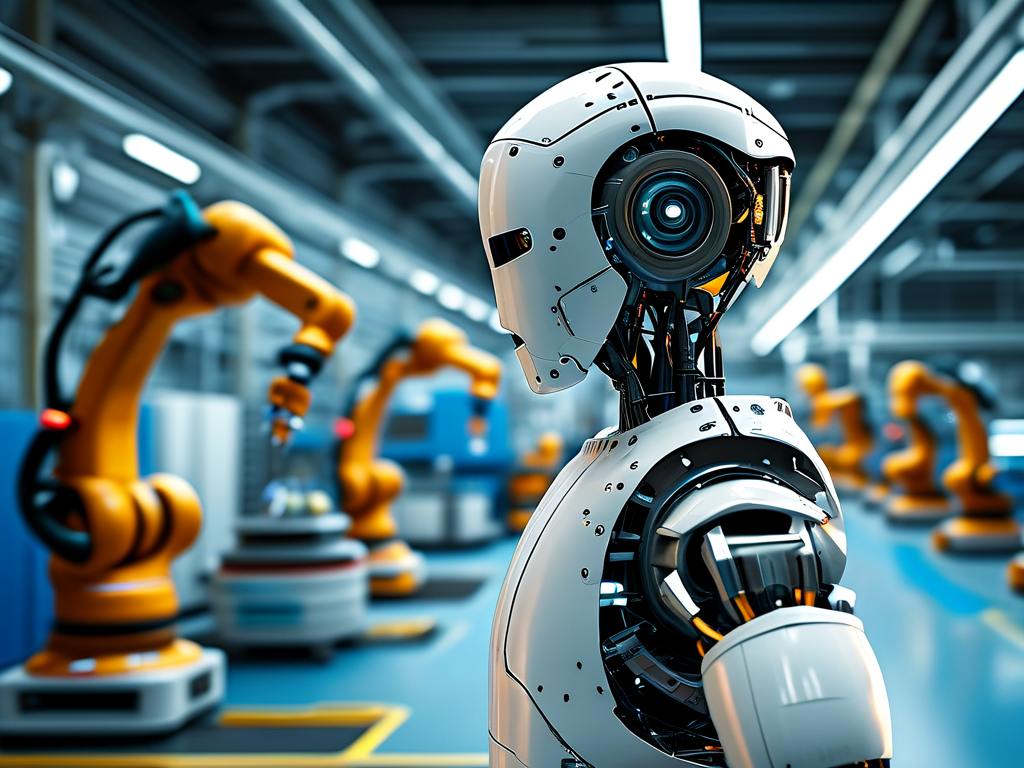

Industrial Implementation and Challenges

Early adopters in aerospace manufacturing report transformative results. Airbus recently implemented Lingchi systems for carbon fiber component separation, reducing material waste from 18% to 2.7% during aircraft decommissioning. The technology's ability to preserve reusable materials creates unprecedented sustainability benefits – a single robotic unit can salvage $2.3 million worth of carbon fiber annually.

However, technical hurdles persist. Current limitations include processing speed constraints (max 15cm²/min for multi-layer materials) and high computational load requirements. The neural networks demand continuous training with material databases, requiring 850TB of structural data for optimal performance. Engineers are developing quantum computing interfaces to address these challenges, with IBM collaborating on hybrid quantum-classical processing units specifically for Lingchi systems.

Ethical Considerations and Future Development

As with any disruptive technology, Lingchi Robotics sparks intense debate. The European Robotics Ethics Board recently issued guidelines prohibiting military adaptation of this technology, while patent disputes over the core pressure-sensing algorithms continue in international courts.

Looking ahead, researchers envision biomimetic applications. Dr. Helena Voss from ETH Zurich leads a team developing medical variants for non-invasive tumor removal. "Our prototype achieved 99.8% cancer cell isolation accuracy in liver tissue simulations," she revealed during last month's World Medical Robotics Congress.

The next five years will likely see Lingchi Robotics transition from industrial specialty to mainstream application. With projected market growth of 47% CAGR until 2030, this technology promises to revolutionize material science, manufacturing, and environmental sustainability. As production costs decrease from current $2.1 million per unit to anticipated $400,000 by 2028, even small-scale recyclers may access this precision disassembly capability.

From smartphone micro-component recovery to historical artifact restoration, the implications of this technology span countless domains. What began as an experimental concept in Shanghai's robotics labs now stands poised to redefine humanity's relationship with material objects – one precise incision at a time.