As China's "River City" accelerates its technological transformation, Wuhan has quietly become a pivotal player in Asia's robotics landscape. Specialized companies importing cutting-edge robotic systems are redefining industrial automation standards while fostering unique cross-border collaborations that set new benchmarks in smart manufacturing.

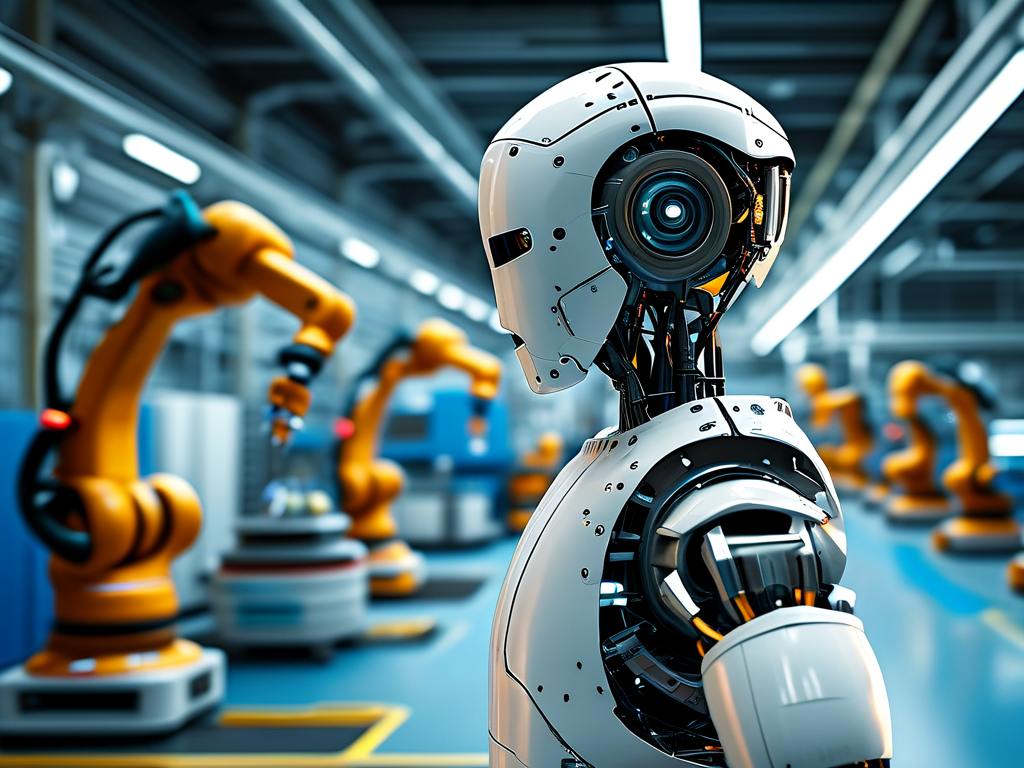

The rise of Wuhan-based robotics importers stems from strategic geographical advantages. Situated at the crossroads of the Yangtze River Economic Belt, these enterprises leverage Wuhan's comprehensive logistics network to efficiently deploy imported robotic arms, AI-driven inspection systems, and modular automation units to manufacturers across central China. Unlike standard equipment distributors, firms like SinoBot Dynamics and Yangtze Automation Solutions have evolved into full-spectrum technology integrators, combining German precision engineering with Japanese maintenance protocols to create hybrid solutions for local industries.

What distinguishes Wuhan's robotics importers is their adaptive customization approach. When a local automotive parts manufacturer required a vision-guided assembly system capable of handling 17 component variants, Wuhan Robotic Synergy partnered with Swiss and South Korean specialists to develop a modular workstation that reduced changeover time by 40%. This symbiotic model – blending imported hardware with domestic software development – has become a hallmark of Wuhan's technology assimilation strategy.

The medical robotics sector exemplifies this fusion. Wuhan MedTech Imports recently deployed Swedish-designed surgical assistance robots at Tongji Hospital, integrated with AI diagnostic modules developed by Wuhan University's AI research center. This cross-pollination has yielded a 28% improvement in orthopedic procedure accuracy while maintaining cost efficiency through localized technical support networks.

However, challenges persist beneath the technological triumphs. Industry insiders note persistent hurdles in firmware localization and the need for specialized maintenance personnel. "The real test lies in sustaining these systems through their lifecycle," remarks Zhang Wei, chief engineer at Hanjiang Robotics. His team has pioneered a dual-certification training program combining European robotics certifications with domestic industrial standards, producing technicians fluent in both international protocols and local manufacturing realities.

Environmental applications demonstrate unexpected innovation paths. A collaborative project between Wuhan EcoTech and Dutch water management specialists has produced amphibious inspection robots now monitoring Yangtze River tributaries. These solar-powered units combine imported sensor arrays with Wuhan-developed data analysis platforms, detecting pollution sources with 92% greater efficiency than previous methods.

The financial architecture supporting these technological imports reveals another layer of sophistication. Wuhan's municipal government has implemented a sliding-scale subsidy program that incentivizes companies to balance imported technology acquisition with domestic R&D investment. This policy has spurred creations like the hybrid logistics robots at Wuhan Port – blending Italian motor systems with Chinese battery technology – which have reduced container handling emissions by 34% since deployment.

Looking ahead, Wuhan's robotics importers are pivoting toward sustainable technology transfer models. The newly established Sino-European Robotics Academy exemplifies this shift, pairing imported expertise in industrial automation with Chinese research in energy-efficient actuators. As these initiatives mature, Wuhan positions itself not merely as an importer of robotic technologies, but as an incubator for next-generation automation solutions reshaping global manufacturing paradigms.