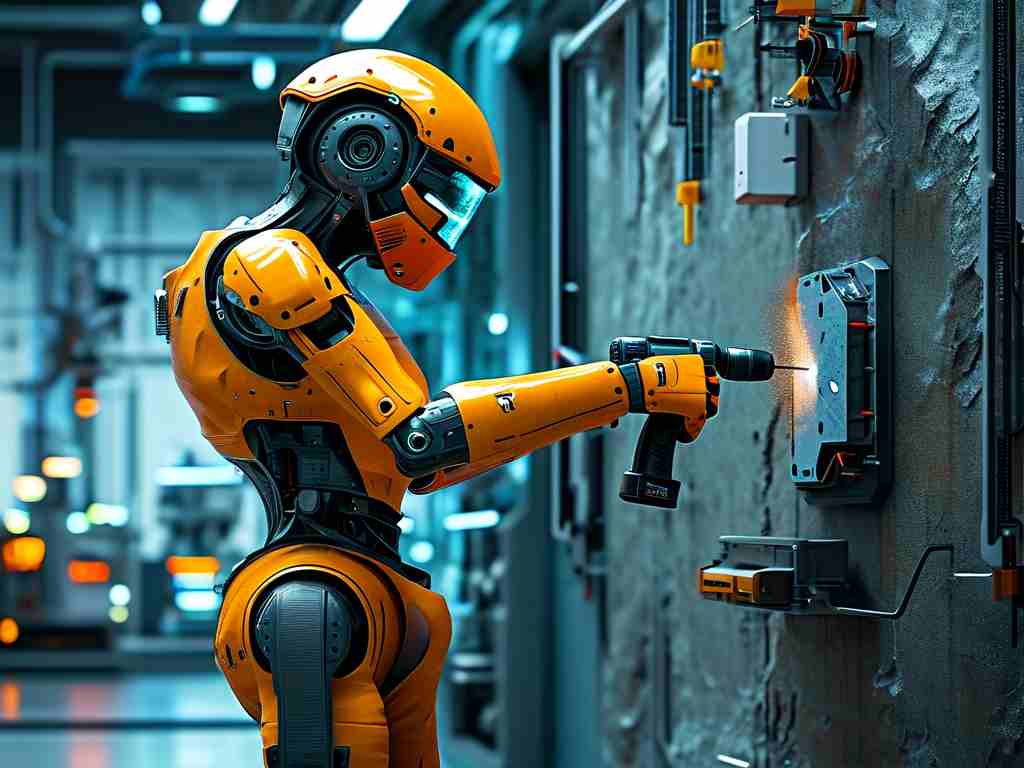

The integration of robotics into construction and renovation processes has revolutionized traditional methods, particularly through innovations like robotic wall-drilling systems. These automated solutions combine precision engineering with advanced algorithms to perform tasks that were once labor-intensive and error-prone. This article explores the technical foundation of robotic drilling technology and its practical implementations across industries.

Core Operational Principles

At its core, robotic wall-drilling technology relies on three interconnected systems: spatial mapping, force feedback control, and adaptive tooling. Spatial mapping begins with 3D laser scanners or depth-sensing cameras that create real-time digital models of the target surface. This data is processed through simultaneous localization and mapping (SLAM) algorithms, enabling the robot to identify optimal drilling points while avoiding embedded obstacles like electrical wiring or plumbing.

The force feedback mechanism represents a critical advancement over conventional drills. Pressure sensors embedded in the robotic arm continuously monitor resistance patterns, adjusting rotational torque and feed rate through closed-loop control systems. For instance, when encountering reinforced concrete, the system automatically reduces drill bit RPM to prevent overheating while maintaining consistent penetration speed.

Key Technological Components

- Path Planning Algorithms: Custom software calculates drilling sequences based on structural blueprints, minimizing unnecessary movements. The system prioritizes cluster patterns for efficiency, such as spiral or grid-based drilling layouts.

- Modular Tool Changers: Advanced models feature automatic bit-swapping mechanisms capable of handling 12-15 tool variations within a single operation cycle.

- Dust Management Systems: Integrated vacuum ports with HEPA filtration maintain visibility and prevent particulate dispersion, crucial for indoor applications.

A practical demonstration can be seen in the DR-450X model's operation:

def auto_drill_sequence(surface_map):

obstacle_coords = detect_obstacles(surface_map)

safe_path = calculate_path(surface_map, obstacle_coords)

for waypoint in safe_path:

adjust_torque(surface_map.material_hardness[waypoint])

activate_drill(waypoint)

collect_debris()

Industry Applications

Beyond basic construction, this technology enables specialized applications:

- Archaeological Preservation: Delicate excavation of historical sites using micro-drilling attachments (0.5-3mm bits) with 0.01mm positional accuracy.

- Emergency Response: Rapid deployment units can create structural access points in disaster zones, operating in environments with temperatures exceeding 60°C or radiation levels up to 500 mSv/h.

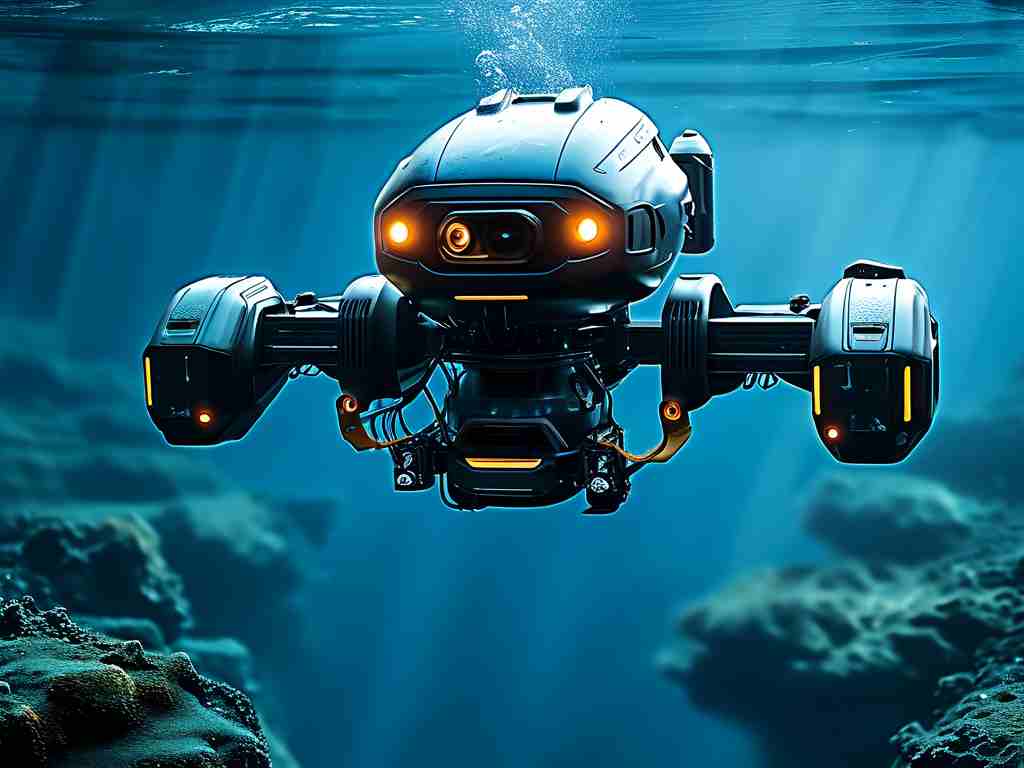

- Teleoperation Solutions: Offshore oil rig maintenance crews in the North Sea now use latency-compensated control systems to operate drilling bots from onshore stations.

Technical Limitations and Innovations

Current systems face challenges with heterogeneous wall compositions. A 2023 field study revealed a 12% accuracy drop when transitioning between materials like brick and steel within the same surface plane. Emerging solutions employ multi-spectral analysis sensors that combine terahertz imaging with ultrasonic testing to map density variations pre-drilling.

Energy consumption remains another focus area. While standard units require 2.8-3.4 kW/h, prototype models using superconducting motor systems have demonstrated 40% power reduction during sustained operations.

Future Development Trajectory

The next generation of drilling robots is expected to incorporate predictive maintenance features using vibration signature analysis. Early trials show 89% accuracy in predicting drill bit failure 15-20 minutes before actual breakdown. Additionally, swarm robotics configurations are being tested, where multiple synchronized units can complete complex drilling patterns 2.3 times faster than single-unit operations.

From smart home installations to industrial infrastructure projects, robotic wall-drilling technology continues to redefine the boundaries of automated construction. As material science and AI coordination algorithms advance, these systems will likely become indispensable tools for building the cities of tomorrow.