Visual robots represent a cutting-edge fusion of artificial intelligence and mechanical systems, enabling machines to perceive and interact with their environment through sight-based technologies. These advanced systems are transforming industries from manufacturing to healthcare by automating complex tasks that once required human vision. At their heart, visual robots rely on a suite of interconnected technologies that work in harmony to process visual data, make decisions, and execute actions. Understanding these core components provides insight into how these robots achieve remarkable precision and autonomy in real-world applications.

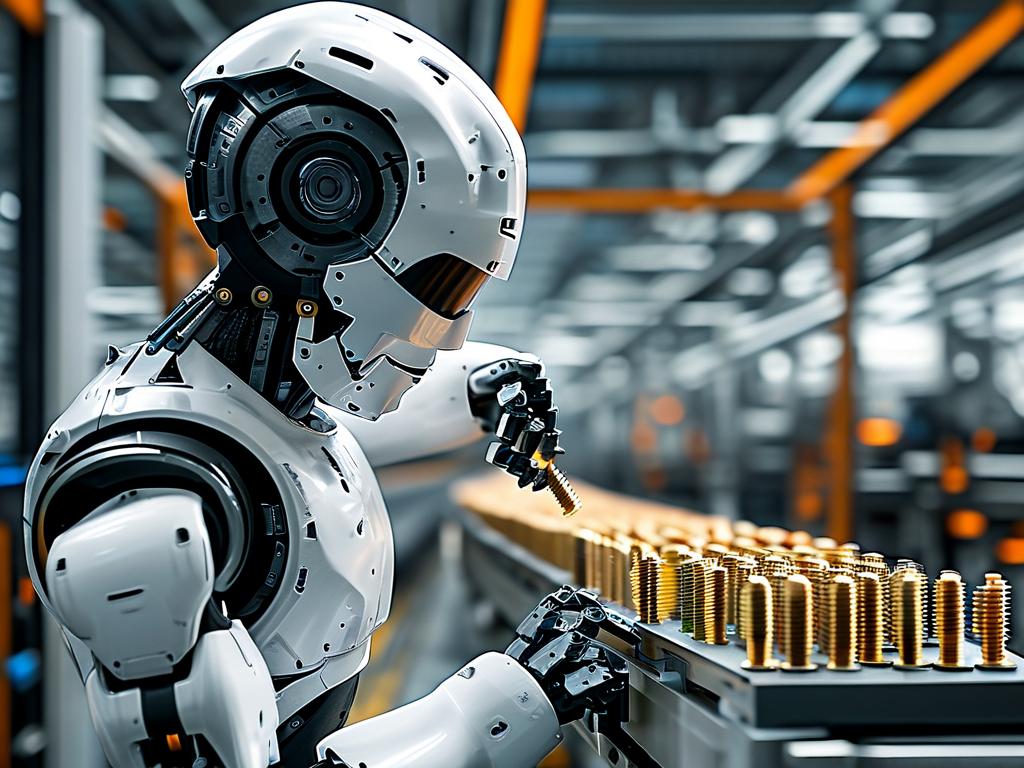

Computer vision forms the foundational layer of visual robots, allowing them to interpret images and videos captured by sensors. This technology involves algorithms that analyze pixel data to detect edges, shapes, and patterns, converting raw visual input into meaningful information. For instance, in industrial settings, computer vision systems identify defects on assembly lines by comparing live footage to predefined templates. This process often employs techniques like edge detection and feature extraction, which mimic human visual processing but at superhuman speeds. As a key enabler, computer vision must handle variations in lighting, occlusion, and perspective, requiring robust software frameworks that adapt dynamically. Over the years, advancements in this area have led to faster processing times and higher accuracy, making visual robots indispensable for quality control and inspection tasks across sectors.

Sensors play a critical role in gathering the visual data that feeds into these systems. Cameras, including RGB and infrared variants, are the most common sensors, providing high-resolution images for detailed analysis. Depth-sensing technologies like LiDAR and structured light scanners add a third dimension, enabling robots to perceive distances and spatial relationships—essential for navigation in cluttered environments. For example, autonomous drones use LiDAR to map terrains and avoid obstacles during flight. These sensors must be calibrated precisely to minimize errors, and they often integrate with inertial measurement units (IMUs) to account for motion and orientation changes. The evolution of sensor tech has seen miniaturization and cost reductions, allowing visual robots to deploy in diverse scenarios, from surgical robots in operating rooms to agricultural bots monitoring crop health.

Machine learning, particularly deep learning, empowers visual robots to learn from data and improve their performance over time. Neural networks, such as convolutional neural networks (CNNs), are trained on vast datasets to recognize objects, faces, and scenes with high fidelity. This technology enables predictive capabilities, like a warehouse robot anticipating inventory movements based on historical patterns. Training involves feeding labeled images into models, adjusting weights through backpropagation to minimize errors. Reinforcement learning further enhances decision-making, allowing robots to optimize actions through trial and error in simulated environments. A simple code snippet illustrates this concept: model = CNN(input_shape); model.train(dataset); predictions = model.predict(new_image). Such ML integration reduces the need for explicit programming, making visual robots more adaptable to unforeseen challenges, such as recognizing novel objects in retail settings.

Navigation and control systems translate visual insights into physical movements, ensuring robots can operate autonomously in dynamic spaces. Simultaneous Localization and Mapping (SLAM) algorithms allow robots to build real-time maps of their surroundings while tracking their position—vital for self-driving cars or delivery bots. Path planning techniques then calculate optimal routes, avoiding obstacles using data from vision sensors. Actuators and motors execute these plans with precision, controlled by feedback loops that adjust for discrepancies. For instance, a visual robot in a factory might use SLAM to navigate around machinery, with control systems fine-tuning gripper movements to handle fragile components. This synergy demands low-latency processing to prevent delays, often leveraging edge computing for on-device analysis. As robotics advances, these systems incorporate predictive analytics to anticipate environmental changes, enhancing safety and efficiency.

Integration of these technologies into cohesive systems is where the true magic happens, enabling end-to-end functionality. Middleware platforms facilitate communication between vision modules, sensors, and control units, ensuring seamless data flow. Cloud computing supports scalability, allowing robots to offload intensive tasks like model training while maintaining real-time operation locally. Applications span from medical diagnostics, where robots assist in surgeries by providing augmented reality overlays, to consumer domains like smart home assistants that recognize gestures. Challenges remain, such as ensuring ethical AI use and addressing privacy concerns with visual data collection. However, ongoing innovations in hardware and software promise to make visual robots more accessible and intelligent. Looking ahead, the convergence with 5G and IoT will unlock new possibilities, solidifying visual robots as pivotal tools in our increasingly automated world.