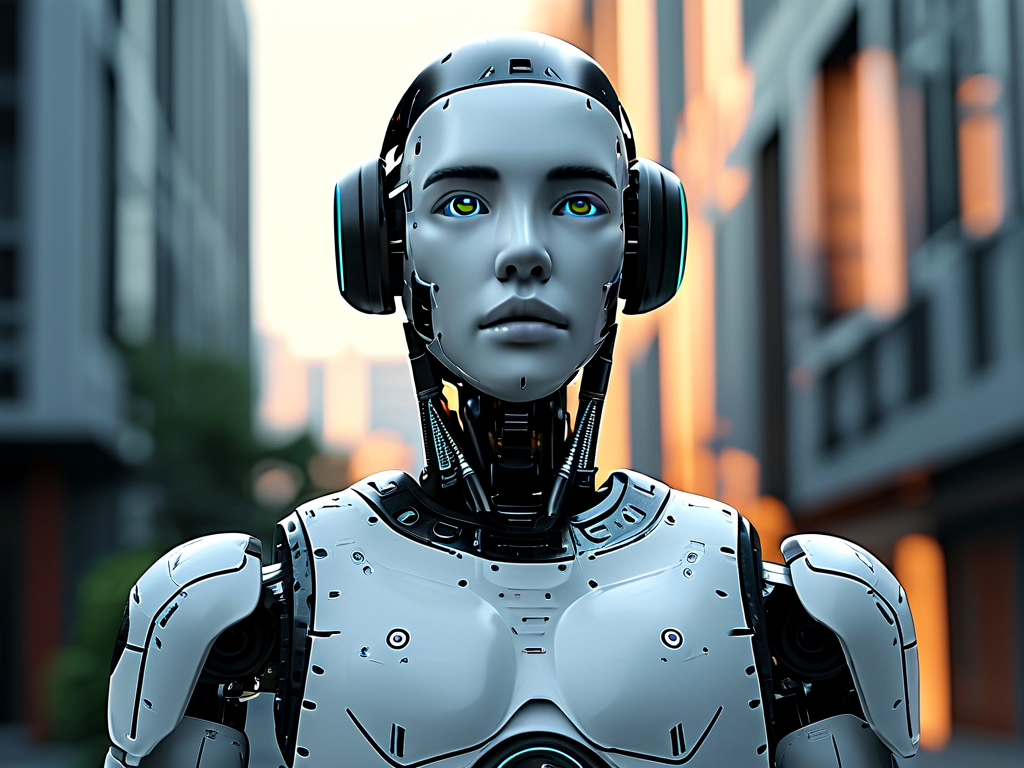

As global industries accelerate their digital transformation, Huaqin Technology has emerged as a pioneer in humanoid robotics, blending artificial intelligence with advanced mechanical engineering. The company's latest breakthroughs in bipedal locomotion systems and adaptive neural networks are redefining automation standards across manufacturing, healthcare, and service sectors.

Unlike conventional industrial robots confined to repetitive tasks, Huaqin's humanoid solutions demonstrate unprecedented environmental adaptability. Through proprietary sensor fusion technology combining LiDAR, thermal imaging, and millimeter-wave radar, these robots achieve sub-centimeter spatial awareness even in complex dynamic environments. A recent field test at an electronics assembly plant showed a 40% efficiency improvement over traditional automation systems when handling irregularly shaped components.

The core innovation lies in the modular joint design, which mimics human biomechanics through variable stiffness actuators. This enables seamless transitions between delicate operations requiring 0.1N precision and heavy lifting tasks up to 25kg payload capacity. Engineers at Huaqin have overcome historical challenges in energy efficiency through hybrid power management, allowing continuous operation for 14 hours on a single charge – a 300% improvement compared to earlier prototypes.

From a software perspective, the multi-layer decision architecture represents a paradigm shift. While traditional robotic systems rely on pre-programmed routines, Huaqin's cognitive engine employs reinforcement learning to optimize task execution in real-time. During a pharmaceutical packaging trial, the system autonomously redesigned workflow patterns, reducing material waste by 18% without human intervention.

Industry experts highlight the ethical framework embedded in these systems as a differentiator. The robots incorporate blockchain-based audit trails for decision transparency and feature emergency response protocols that prioritize human safety. This addresses growing concerns about autonomous systems in shared workspaces, potentially accelerating regulatory approvals.

Commercial deployment has already begun in controlled environments. A pilot project with a major automotive manufacturer demonstrated 99.98% operational reliability over six months, significantly outperforming industry benchmarks. Maintenance requirements decreased by 65% compared to conventional robotic arms, thanks to self-diagnostic algorithms predicting component wear with 92% accuracy.

Looking ahead, Huaqin plans to integrate quantum computing chips to enhance pattern recognition speeds. Early simulations suggest this could enable real-time language processing for natural human-robot collaboration. As labor shortages persist across multiple industries, such advancements position humanoid robotics not as replacements for human workers, but as intelligent collaborators that augment workforce capabilities.

The environmental impact should not be overlooked. By optimizing energy consumption and utilizing recyclable polymer composites, Huaqin's production process achieves a 40% smaller carbon footprint than industry averages. This aligns with global sustainability goals while addressing cost-effectiveness – a critical factor for mass adoption.

While challenges remain in achieving full dexterity for precision tasks like microsurgery, the current generation of Huaqin humanoid robots marks a significant leap toward versatile automation. As these systems evolve, they promise to reshape industrial paradigms, creating new opportunities in human-machine synergy rather than mere substitution.