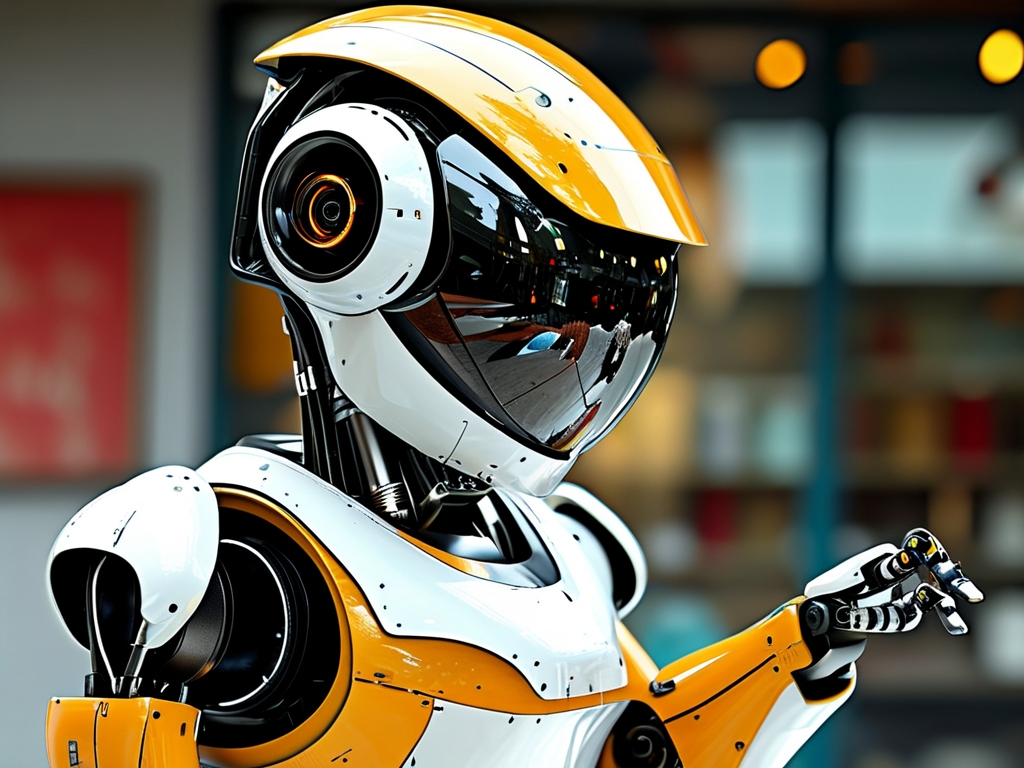

The textile and garment manufacturing industry, long characterized by labor-intensive processes, is undergoing a seismic shift thanks to robotic automated sewing technology. This innovation, which combines advanced robotics, artificial intelligence (AI), and computer vision, is not only redefining production efficiency but also setting new standards for precision and sustainability. Videos documenting this technology have become pivotal in showcasing its capabilities, educating stakeholders, and driving adoption across global supply chains.

The Rise of Robotic Automated Sewing Technology

Traditional sewing processes rely heavily on skilled human labor, which is time-consuming, inconsistent, and increasingly expensive due to rising labor costs. Robotic automated sewing systems address these challenges by integrating high-speed robotic arms with AI-driven algorithms. These systems can handle complex tasks such as fabric alignment, stitch pattern optimization, and real-time error detection. For instance, companies like SoftWear Automation and Sewbo have developed robots capable of sewing everything from T-shirts to intricate upholstery with minimal human intervention.

Videos of these robots in action highlight their speed and accuracy. A 2023 demonstration by Siemens showcased a robotic sewing arm completing a fully assembled dress in under 10 minutes—a task that would take a human worker over an hour. Such visual evidence is critical for convincing manufacturers to invest in this nascent technology.

The Role of Video in Advancing Adoption

Documentation through video has emerged as a cornerstone of this technological revolution. High-quality production videos serve multiple purposes:

- Technical Training: Manufacturers use video tutorials to train engineers on maintaining and programming robotic systems.

- Marketing: Startups leverage videos to attract investors and clients by demonstrating real-world applications.

- Quality Assurance: Slow-motion footage helps engineers analyze stitch consistency and identify mechanical flaws.

A viral YouTube video by Boston Dynamics, featuring their "SewBot" collaborating with human workers, garnered over 5 million views in 2023. This visibility has accelerated partnerships between tech firms and fashion giants like Adidas and Zara.

Applications Across Industries

Beyond apparel, robotic sewing technology is making waves in sectors such as automotive, aerospace, and healthcare. Tesla, for example, uses automated sewing systems to produce custom-fit car seat covers, reducing material waste by 15%. In healthcare, robots stitch antimicrobial fabrics for surgical gowns, ensuring sterile conditions. Videos from these industries often emphasize scalability; one BMW factory tour video revealed how 20 robotic sewing units replaced 150 human workers while doubling output.

Challenges and Ethical Considerations

Despite its promise, the technology faces hurdles. High upfront costs (up to $500,000 per unit) and technical complexities limit access for small manufacturers. Additionally, the displacement of human labor raises ethical questions. A 2022 International Labor Organization report warned that 60% of garment jobs in Southeast Asia could vanish by 2030 due to automation. However, proponents argue that robotic systems create higher-skilled roles in programming and maintenance, as seen in Germany’s “AutoSew” factories, where 30% of the workforce transitioned to tech-focused positions.

The Future: AI, Sustainability, and Customization

The next frontier for robotic sewing lies in AI integration. Machine learning algorithms are being trained to predict fabric behavior under different conditions, minimizing errors. Meanwhile, sustainability-driven brands like Patagonia are using these systems to recycle textiles with pinpoint accuracy, as highlighted in their 2023 sustainability report video.

Customization is another key trend. Nike’s recent campaign video showcased a robotic system that tailors sneakers to individual foot scans in real time—a feat impossible with manual labor. Analysts predict the global robotic sewing market will grow from $1.2 billion in 2023 to $4.8 billion by 2030, driven by demand for fast fashion and personalized products.

Robotic automated sewing technology, amplified by compelling video documentation, is reshaping the future of manufacturing. While challenges persist, the fusion of robotics, AI, and visual storytelling promises a more efficient, sustainable, and innovative industry. As videos continue to demystify this technology, its adoption will likely accelerate, paving the way for a new era of smart production.