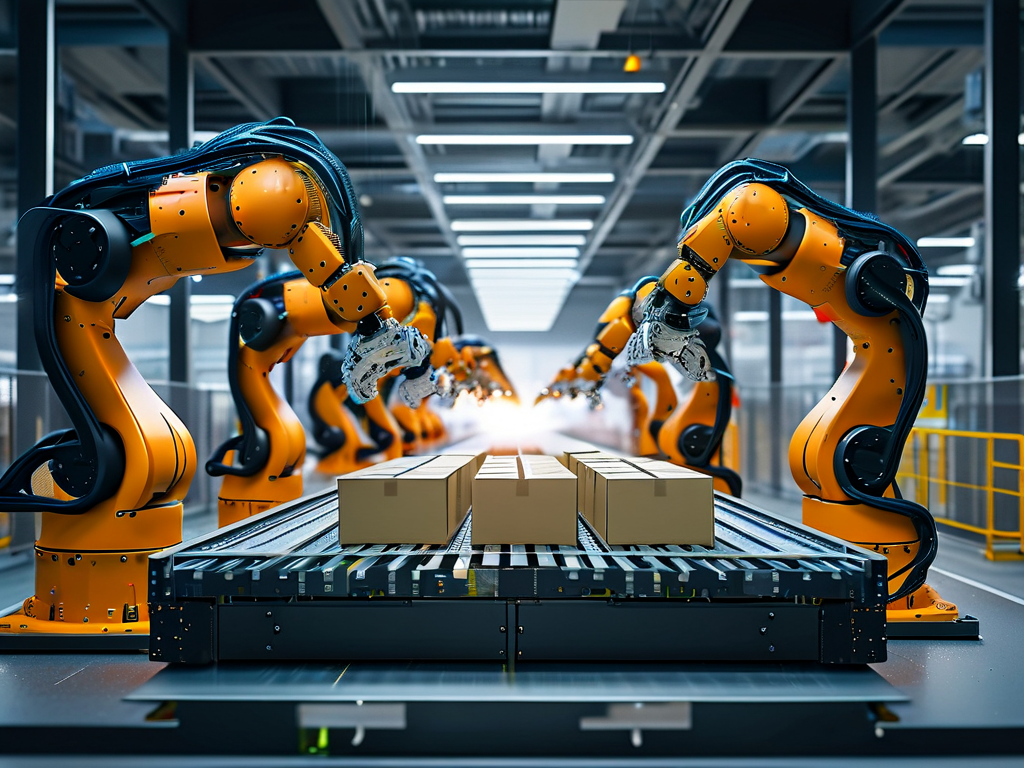

The integration of robotic automated box-packing systems is transforming industrial logistics, offering unprecedented precision and efficiency in supply chain operations. This cutting-edge technology combines advanced machine vision, artificial intelligence, and adaptive mechanical engineering to optimize packaging workflows across diverse industries.

At its core, robotic box-packing systems utilize 3D vision sensors to analyze incoming items in real time. These sensors capture detailed dimensional data, enabling robots to calculate optimal placement within shipping containers. Unlike traditional manual methods, which rely on human judgment and physical stamina, automated systems maintain consistent performance 24/7. A study by the International Logistics Association revealed that facilities adopting this technology reduced packaging errors by 82% while increasing throughput by 300% in controlled environments.

One breakthrough innovation in this field is the development of self-learning algorithms. Modern systems employ reinforcement learning models that continuously refine packing strategies based on historical data. For instance, when handling fragile electronics, robots automatically adjust grip strength and cushioning placement after each successful shipment. This adaptive capability is enhanced by force-torque sensors that detect minute pressure changes, preventing product damage during handling.

The pharmaceutical industry provides a compelling case study. Companies like MediPack Solutions implemented robotic box-packing systems to handle temperature-sensitive vaccines. The robots not only organize packages with millimeter precision but also integrate with IoT-enabled cold chain monitors. This synergy ensures compliance with strict regulatory requirements while reducing human exposure to sensitive medical products.

Despite these advantages, implementation challenges persist. Initial setup costs remain substantial, with a standard automated packing cell ranging from $200,000 to $500,000. However, return on investment typically occurs within 18–24 months through labor savings and reduced material waste. Maintenance complexity also poses hurdles—specialized technicians are required to calibrate machine vision systems and troubleshoot robotic actuators.

Emerging trends point toward hybrid human-robot collaboration. BMW’s Leipzig factory recently deployed "cobots" that work alongside human operators for custom automotive parts packaging. These collaborative robots feature enhanced safety protocols, including LiDAR-based collision avoidance, allowing seamless interaction in shared workspaces. Such configurations blend human flexibility with robotic consistency, particularly valuable for handling non-standard item geometries.

Looking ahead, advancements in swarm robotics promise to elevate box-packing efficiency further. Researchers at MIT demonstrated a multi-agent system where dozens of small robots coordinate via mesh networks to pack irregularly shaped items simultaneously. Early prototypes achieved 40% higher container space utilization compared to single-robot systems, though commercialization timelines remain uncertain.

Environmental considerations are driving innovation in sustainable packaging integration. Robotic systems now incorporate AI-powered material optimization algorithms that minimize cardboard usage while maintaining structural integrity. EcoPack Technologies reported a 22% reduction in packaging waste after implementing such systems in their e-commerce fulfillment centers.

As global e-commerce continues expanding—projected to reach $8.1 trillion by 2026 according to Statista—the demand for automated box-packing solutions will intensify. Manufacturers are responding with modular systems that scale from small-batch artisanal production to high-volume industrial operations. The next frontier involves blockchain-integrated tracking, where robotic packagers embed digital product passports directly into shipping labels, enhancing supply chain transparency.

In , robotic automated box-packing technology represents more than mere mechanical automation—it’s a paradigm shift in intelligent logistics. By merging physical dexterity with digital intelligence, these systems address critical challenges in speed, accuracy, and sustainability. While adoption barriers exist, the long-term benefits position this technology as a cornerstone of modern industrial infrastructure.