Dongguan, a manufacturing powerhouse in China’s Guangdong Province, has emerged as a leader in adopting and innovating palletizing robot technology. As industries worldwide prioritize efficiency and automation, Dongguan’s advancements in this field are reshaping logistics, production lines, and supply chain management. This article explores the cutting-edge developments, applications, and future prospects of palletizing robotics in Dongguan.

The Rise of Palletizing Robotics in Dongguan

Dongguan’s manufacturing sector, known for its electronics, textiles, and machinery production, has faced increasing pressure to optimize operations. Traditional manual palletizing—stacking goods onto pallets for storage or transport—is labor-intensive and prone to errors. To address these challenges, local enterprises began integrating automated palletizing systems as early as 2015. Today, over 60% of Dongguan’s mid-to-large-scale factories utilize robotic palletizers, driven by the city’s push for “smart manufacturing” under China’s Made in 2025 initiative.

Key Technological Innovations

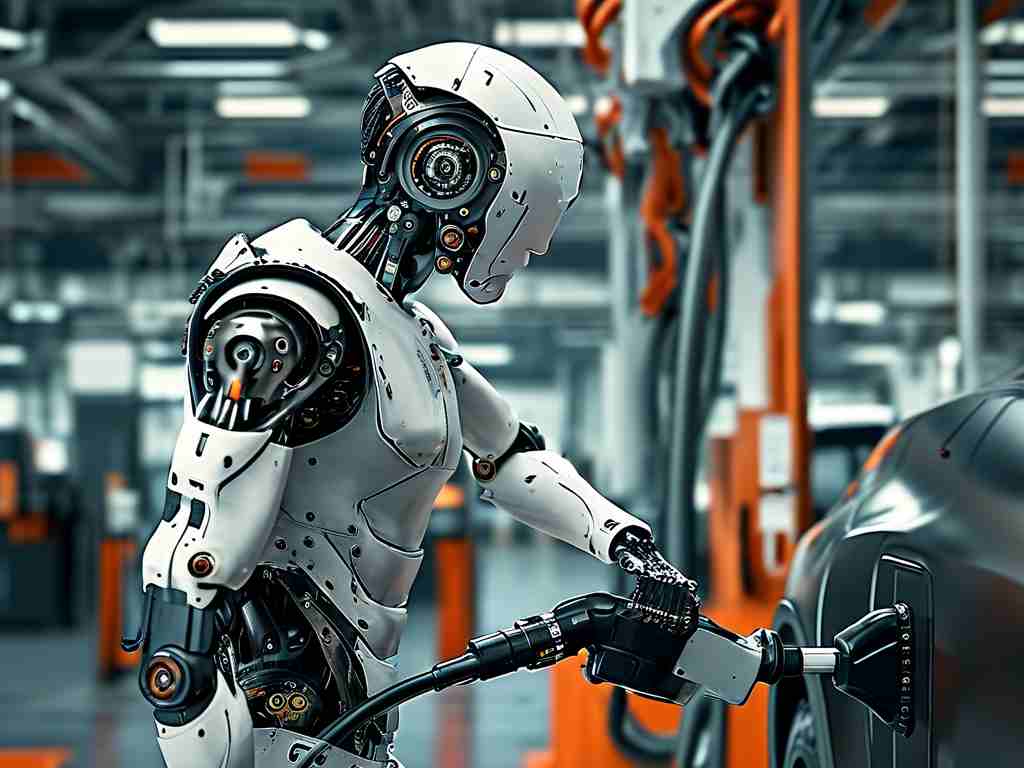

Dongguan-based companies like ESTUN Robotics and INOVANCE have pioneered modular palletizing solutions tailored for diverse industries. These robots feature adaptive grippers capable of handling irregularly shaped items, from delicate circuit boards to heavy automotive parts. Advanced vision systems enable real-time adjustments, ensuring precise stacking even with variable product sizes. For example, a recent deployment at a Dongguan beverage plant achieved a 99.8% accuracy rate while palletizing 1,200 bottles per hour—tripling manual output.

Another breakthrough is the integration of IoT (Internet of Things) connectivity. Sensors embedded in palletizing robots collect data on performance metrics, energy consumption, and maintenance needs. This data is analyzed using AI algorithms to predict equipment failures, reducing downtime by up to 40%. Such innovations have positioned Dongguan as a hub for R&D in collaborative robots (cobots), which work safely alongside human operators in hybrid workflows.

Industry Applications and Economic Impact

The versatility of Dongguan’s palletizing robots has led to widespread adoption across sectors:

- Electronics Manufacturing: Robots stack fragile components with micron-level precision, minimizing damage during transit.

- Food and Beverage: Hygienic stainless-steel models meet strict sanitation standards while handling perishable goods.

- Logistics: Autonomous mobile robots (AMRs) combine palletizing with real-time inventory tracking in warehouses.

Economically, automation has helped manufacturers offset rising labor costs. A 2023 study by the Dongguan Robotics Association revealed that factories using palletizing robots reduced labor expenses by 35% annually while boosting output consistency. Additionally, the local robotics industry generated over $2.1 billion in revenue last year, attracting investment from global players like ABB and FANUC.

Challenges and Future Directions

Despite progress, challenges remain. Small and medium-sized enterprises (SMEs) often struggle with the upfront costs of robotic systems. To address this, Dongguan’s government offers subsidies covering up to 20% of automation equipment purchases. Training programs at institutions like the Guangdong University of Technology also aim to bridge the skills gap in robot maintenance and programming.

Looking ahead, developers are focusing on lightweight, energy-efficient models powered by renewable energy. Hybrid systems combining 5G connectivity and edge computing are also in testing, promising near-instantaneous response times for complex tasks. By 2030, experts predict that Dongguan’s palletizing robots will dominate Southeast Asian markets, further solidifying the city’s role in global industrial automation.

Dongguan’s palletizing robot technology exemplifies the synergy between innovation and industrial demand. By continuously refining hardware and software, the city not only enhances local manufacturing competitiveness but also sets benchmarks for smart logistics worldwide. As automation becomes indispensable, Dongguan’s expertise will undoubtedly influence the next generation of industrial robotics.