In recent years, Foshan, a bustling manufacturing hub in China's Guangdong Province, has emerged as a global leader in advanced robotics technology. Among its most groundbreaking contributions is the development of Autonomous Mobile Robots (AMR), which are revolutionizing industries from logistics to automotive manufacturing. This article explores how Foshan's AMR robotics ecosystem is reshaping automation, the technological breakthroughs driving its success, and the implications for global industrial trends.

The Rise of Foshan's AMR Ecosystem

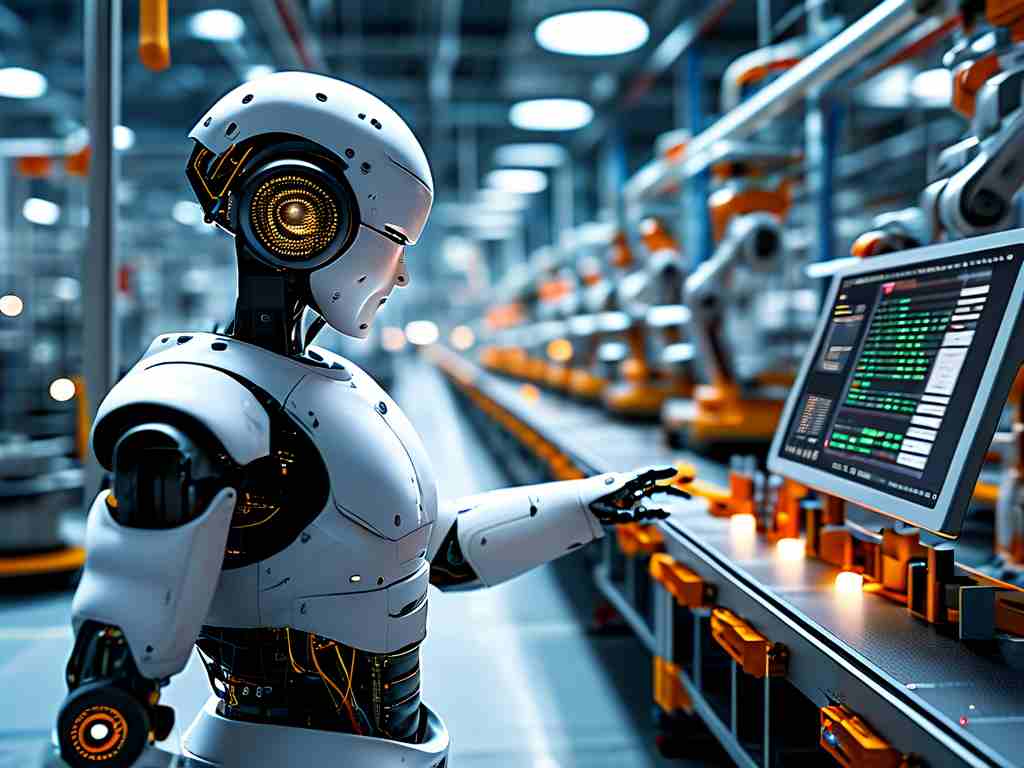

Foshan's journey into AMR robotics began as a response to the growing demand for flexible and intelligent automation solutions. Traditional industrial robots, while effective for repetitive tasks, struggled to adapt to dynamic environments. AMRs, equipped with AI-driven navigation, real-time data processing, and collaborative capabilities, offered a solution. Leveraging its robust manufacturing infrastructure and government-supported innovation policies, Foshan quickly became a testing ground for AMR applications.

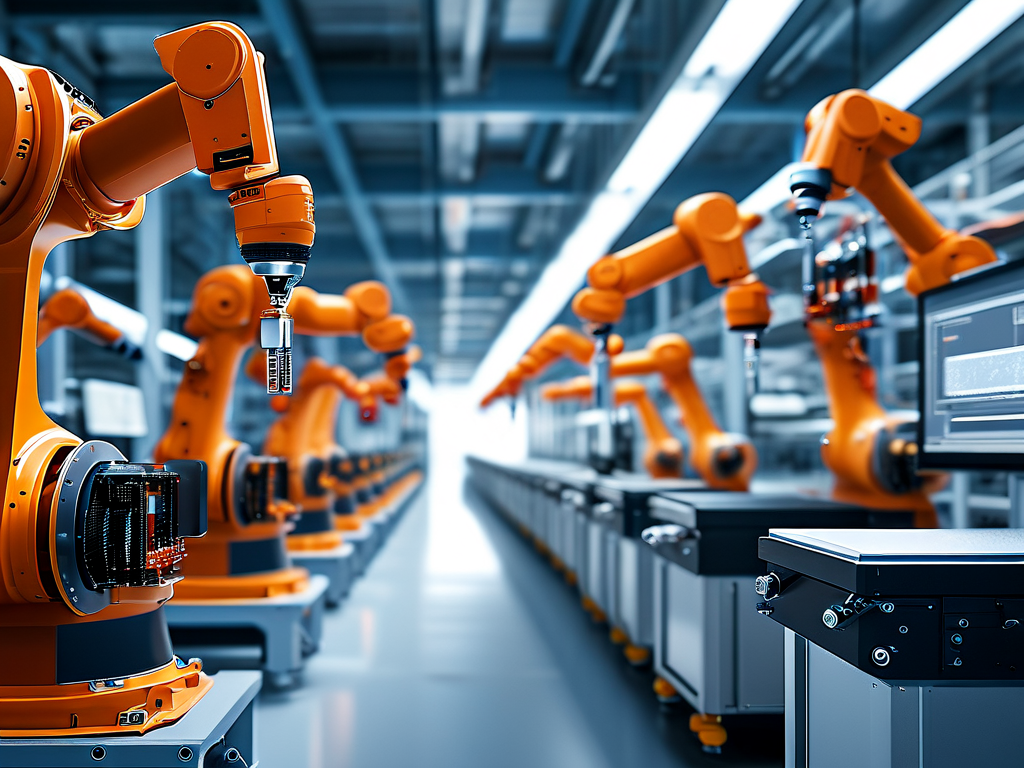

Local companies like Midea Group and Galaxy Robotics spearheaded R&D efforts, integrating AMRs into their production lines. These robots excel in material handling, warehouse management, and even precision assembly tasks. For example, Midea's smart factories now deploy fleets of AMRs that communicate seamlessly with IoT systems, reducing human intervention by 40% while boosting productivity.

Technological Innovations Defining Foshan's AMR Solutions

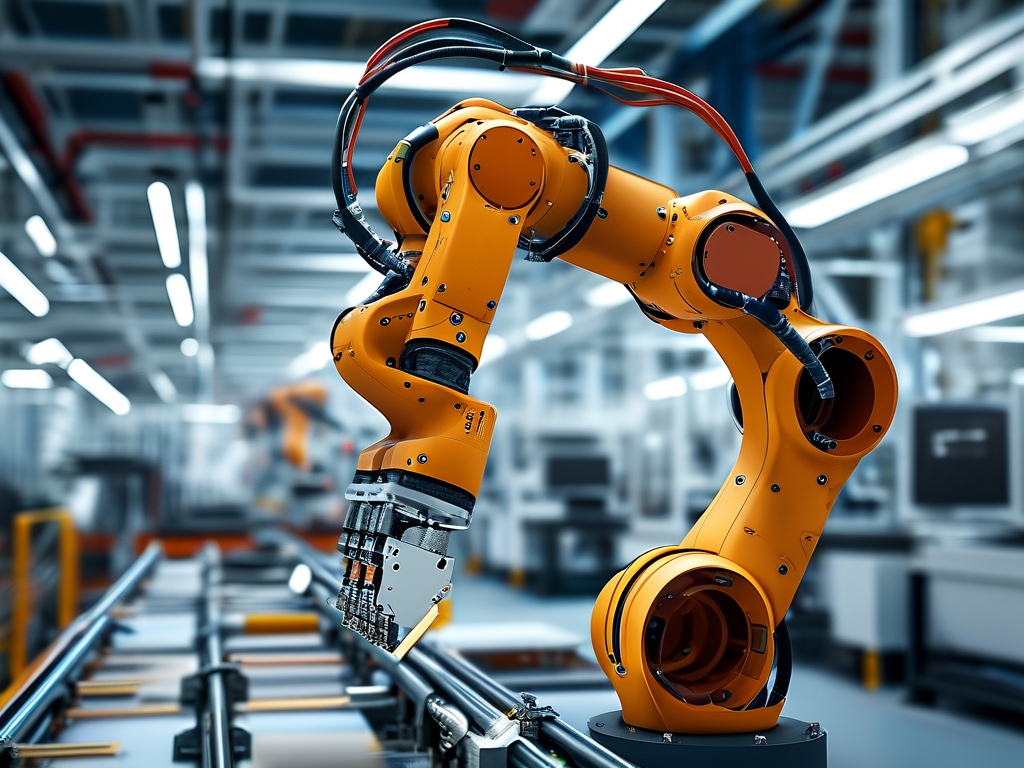

- AI-Powered Navigation: Foshan's AMRs utilize advanced SLAM (Simultaneous Localization and Mapping) algorithms, enabling them to navigate complex environments without predefined paths. This flexibility is critical for industries like e-commerce, where warehouse layouts frequently change.

- Human-Robot Collaboration: Unlike traditional robots confined to safety cages, Foshan's AMRs feature sensors and vision systems that allow safe interaction with human workers. This hybrid workforce model is transforming sectors such as electronics assembly.

- Energy Efficiency: Innovations in lithium battery technology and wireless charging systems enable Foshan's AMRs to operate for 12+ hours on a single charge, minimizing downtime.

- Cloud Integration: By connecting AMRs to cloud platforms, companies can optimize fleet management, predict maintenance needs, and analyze operational data in real time.

Industry Applications and Case Studies

- Automotive Manufacturing: A Foshan-based auto parts supplier reduced production cycle times by 25% using AMRs for just-in-time component delivery.

- Pharmaceuticals: AMRs in sterile environments ensure precise handling of sensitive materials, complying with stringent regulatory standards.

- Retail Logistics: A major e-commerce platform in Foshan cut order fulfillment times by 30% through AMR-driven sorting systems.

Economic and Social Impact

The AMR boom has solidified Foshan's reputation as a "City of Robotics." Over 500 local enterprises now specialize in robotics, attracting $2.3 billion in investments in 2023 alone. The sector has also created 15,000 high-skilled jobs, from AI engineers to robotics maintenance technicians.

However, challenges persist. The high initial cost of AMR deployment remains a barrier for small manufacturers. Additionally, global supply chain disruptions have highlighted dependencies on imported semiconductor components.

Global Competitiveness and Future Outlook

Foshan's AMR advancements position China as a formidable competitor against robotics giants like Germany and Japan. Collaborations with international research institutes, such as the Fraunhofer Institute, are accelerating cross-border innovation.

Looking ahead, Foshan aims to integrate 5G connectivity and edge computing into AMRs, enabling faster decision-making in real-time scenarios. The city also plans to expand AMR applications to agriculture and healthcare, such as autonomous crop-monitoring robots and hospital delivery systems.

Foshan's AMR robotics technology exemplifies how regional innovation ecosystems can drive global industrial transformation. By blending cutting-edge AI, strategic policy support, and a culture of experimentation, Foshan is not only advancing its own economic agenda but also setting new benchmarks for intelligent automation worldwide. As industries increasingly prioritize agility and sustainability, Foshan's AMR solutions offer a blueprint for the future of manufacturing-one where humans and robots collaborate to achieve unprecedented efficiency.