The integration of embedded systems into cable manufacturing and infrastructure management has become a cornerstone of modern industrial innovation. As cable companies strive to meet the growing demands for high-speed data transmission, energy efficiency, and operational reliability, embedded development solutions offer a transformative pathway. This article explores how tailored embedded systems empower cable companies to optimize production, enhance product performance, and future-proof their operations in an increasingly connected world.

The Role of Embedded Systems in Cable Industries

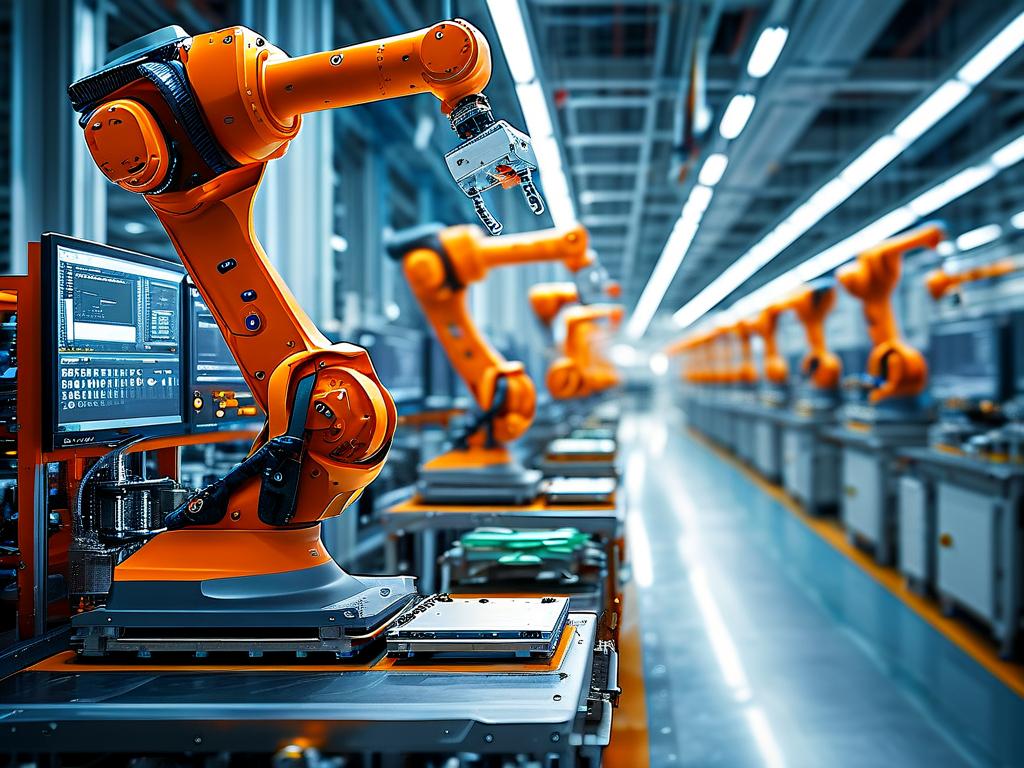

Embedded systems, characterized by their specialized hardware and software integration, are pivotal in addressing the unique challenges faced by cable companies. These systems enable real-time monitoring, automation, and precision control across manufacturing processes. For instance, in coaxial or fiber-optic cable production, embedded controllers regulate temperature, tension, and extrusion rates to ensure consistent product quality. Advanced sensors paired with microprocessors detect microfractures or impedance mismatches, minimizing defects and reducing waste.

Moreover, embedded solutions facilitate smart grid compatibility for power cable providers. By embedding communication modules and IoT-enabled devices into cable networks, utilities gain remote diagnostics, load balancing, and fault detection capabilities. This not only improves grid resilience but also accelerates response times during outages.

Key Components of an Embedded Development Framework

-

Customized Hardware Design: Cable-specific embedded systems require robust hardware tailored to environmental conditions. For underwater or underground cables, corrosion-resistant microcontrollers and moisture-proof sensors are critical. Companies like VoltEdge Technologies have pioneered modular designs that allow scalability across different cable types, from high-voltage transmission lines to low-latency data cables.

-

Real-Time Operating Systems (RTOS): RTOS ensures deterministic behavior for time-sensitive tasks. In cable testing laboratories, RTOS-driven systems perform synchronized signal integrity analyses, identifying latency or crosstalk issues within nanoseconds. Open-source platforms like FreeRTOS are increasingly adopted for their flexibility and cost-effectiveness.

-

Data Analytics and Machine Learning Integration: Embedded systems now leverage edge computing to process data locally. For example, predictive maintenance algorithms analyze vibration patterns in cable machinery to forecast wear-and-tear, reducing unplanned downtime. Machine learning models also optimize material usage by predicting optimal insulation thickness based on historical performance data.

-

Cybersecurity Protocols: As cable networks become interconnected, embedded firmware must prioritize security. Encryption modules, secure boot mechanisms, and regular over-the-air (OTA) updates protect against cyber threats. The 2023 Global Cable Security Report highlighted that 68% of cable breaches originated from unpatched embedded devices, underscoring the need for robust safeguards.

Case Study: Smart Grid Implementation in Europe

A leading European cable manufacturer, TeraCable Solutions, partnered with an embedded systems developer to deploy a smart grid project across Scandinavia. By embedding LoRaWAN-enabled sensors and gateways into their high-voltage cables, the company achieved:

- A 40% reduction in energy loss through dynamic load management.

- Real-time fault localization, cutting average repair time from 12 hours to 45 minutes.

- Integration with renewable energy sources, enabling seamless solar/wind power assimilation.

This $120 million initiative not only boosted operational efficiency but also positioned TeraCable as a sustainability leader, attracting ESG-focused investors.

Future Trends and Challenges

The next wave of embedded innovation will focus on AI-driven autonomous systems. For instance, self-healing cables with embedded AI chips could reroute signals autonomously during physical damage. However, challenges persist:

- Standardization: Fragmented communication protocols (e.g., Modbus vs. PROFIBUS) complicate interoperability.

- Power Constraints: Energy-harvesting embedded devices (e.g., piezoelectric sensors) are still in experimental stages.

- Skill Gaps: A 2024 survey by Embedded Tech Insights revealed that 52% of cable firms lack in-house expertise to manage advanced embedded projects.

Embedded development solutions are redefining the cable industry's capabilities, merging cutting-edge technology with practical applications. By adopting modular, secure, and intelligent systems, cable companies can not only streamline operations but also pioneer innovations that address global connectivity demands. As 5G, IoT, and smart cities proliferate, the synergy between cable engineering and embedded systems will remain a linchpin of progress-transmitting not just data or power, but the very foundation of a digitally interconnected future.