The embedded development process is a structured methodology for creating specialized computing systems designed to perform dedicated functions. Visual representations, such as flowcharts and diagrams, play a critical role in streamlining this complex workflow. This article explores the embedded development lifecycle, supported by illustrative diagrams, to demystify its stages and highlight best practices.

1. Embedded Development Overview

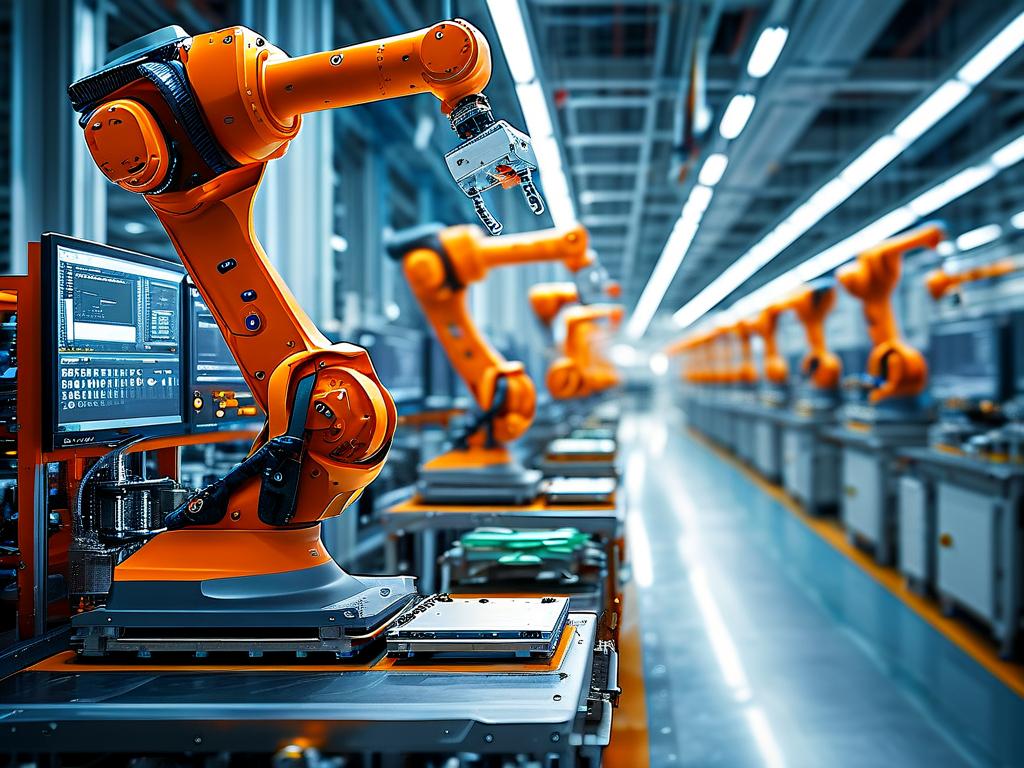

Embedded systems are everywhere—from medical devices to automotive controls. Unlike general-purpose computers, these systems prioritize efficiency, reliability, and real-time performance. The development process typically follows a phased approach, combining hardware and software design, testing, and deployment. A well-defined workflow diagram helps teams align on objectives, identify dependencies, and mitigate risks early.

2. Key Stages in the Embedded Development Process

Phase 1: Requirements Analysis

Every project begins with understanding user needs and technical constraints. A requirements diagram maps functional specifications (e.g., sensor accuracy) and non-functional requirements (e.g., power consumption). This stage often involves stakeholder interviews and market research to define the system’s scope.

Phase 2: System Architecture Design

Here, developers create a high-level block diagram showing hardware-software interactions. For example, a microcontroller, memory modules, and peripherals are outlined alongside software components like drivers and communication protocols. This visual blueprint ensures seamless integration between subsystems.

Phase 3: Hardware-Software Co-Design

Embedded systems require tight synchronization between hardware and firmware. A co-design flowchart illustrates iterative processes such as PCB layout optimization and firmware debugging. Tools like MATLAB or Simulink simulate interactions to validate performance before physical prototyping.

Phase 4: Implementation

In this phase, developers write code (often in C/C++ or Python) and assemble hardware components. A state machine diagram models system behavior under different conditions, ensuring logic aligns with requirements. Version control systems like Git track code changes, while CI/CD pipelines automate testing.

Phase 5: Testing and Validation

Rigorous testing is critical. A test case diagram outlines scenarios like stress testing, boundary analysis, and compliance checks. Hardware-in-the-loop (HIL) testing validates real-world performance, while tools like JTAG debuggers diagnose issues at the register level.

Phase 6: Deployment and Maintenance

Post-deployment, embedded systems require updates and patches. A maintenance flowchart guides remote firmware updates or hardware replacements. Metrics like mean time between failures (MTBF) are monitored to ensure long-term reliability.

3. Role of Visual Tools in Embedded Development

Diagrams simplify complexity in several ways:

- Clarity: Flowcharts break down multi-step processes, such as boot sequences or interrupt handling.

- Collaboration: Unified Modeling Language (UML) diagrams standardize communication across cross-functional teams.

- Error Reduction: Timing diagrams expose race conditions or latency issues in real-time systems.

For instance, a data flow diagram (DFD) reveals how sensor data moves through processing layers, helping optimize memory usage. Similarly, a Gantt chart tracks project timelines, ensuring milestones like prototype reviews stay on schedule.

4. Challenges and Mitigation Strategies

Embedded development faces unique hurdles:

- Resource Constraints: Limited processing power or memory demands optimized code. Tools like static analyzers identify inefficiencies.

- Cross-Domain Expertise: Engineers must understand both analog circuits and RTOS principles. Training programs and modular design mitigate knowledge gaps.

- Security Risks: IoT devices are vulnerable to attacks. Threat modeling diagrams help embed encryption and secure boot mechanisms.

5. Case Study: Automotive ECU Development

Consider an electronic control unit (ECU) for engine management. The workflow diagram starts with requirements (e.g., emissions compliance), progresses to hardware selection (microcontroller with CAN bus support), and includes safety-critical testing via ISO 26262 standards. Visual tools like AUTOSAR architecture diagrams ensure interoperability across automotive subsystems.

6. Future Trends

Emerging technologies are reshaping embedded development:

- AI Integration: Machine learning models deployed on edge devices require optimized inference diagrams.

- Low-Code Platforms: Drag-and-drop interfaces accelerate prototyping but still rely on backend workflow visualizations.

- Sustainability: Energy profiling diagrams guide the design of eco-friendly systems.

The embedded development process thrives on visual organization. From initial requirements to post-deployment updates, diagrams act as a universal language for engineers, managers, and stakeholders. By adopting structured workflows and leveraging modern tools, teams can deliver robust, scalable embedded systems that power the technology of tomorrow.