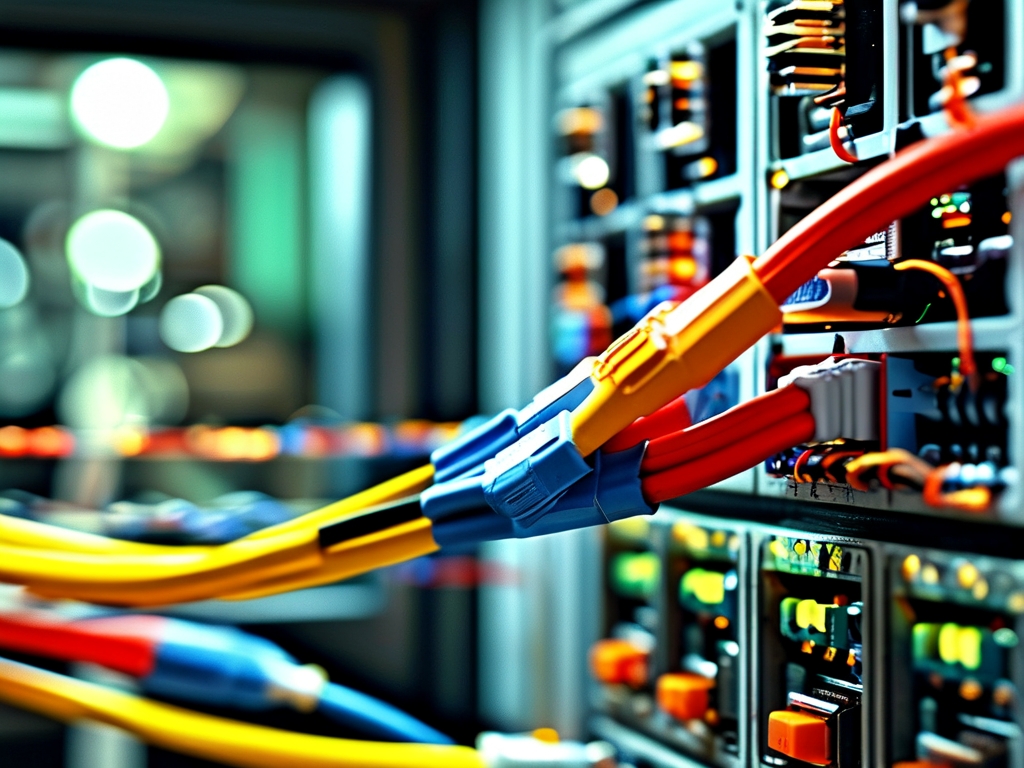

The integration of embedded systems into cable manufacturing and infrastructure management has become a cornerstone of modern industrial innovation. Cable companies worldwide are increasingly adopting embedded development projects to enhance operational efficiency, improve product reliability, and meet the growing demands of smart infrastructure. This article explores the transformative role of embedded systems in the cable industry, focusing on technical challenges, implementation strategies, and real-world applications.

1. The Rise of Embedded Systems in Cable Technology

Embedded development in cable companies revolves around designing specialized hardware and software solutions tailored to monitor, control, and optimize cable networks. Traditional cable systems often relied on manual oversight, leaving room for human error and inefficiency. Embedded systems address these gaps by enabling real-time data acquisition, predictive maintenance, and automated fault detection. For instance, sensors embedded within power cables can detect temperature fluctuations, insulation degradation, or load imbalances, transmitting alerts to centralized systems before failures occur.

The shift toward Industrial Internet of Things (IIoT) has further accelerated this trend. Modern embedded platforms integrate wireless communication protocols like LoRaWAN, Zigbee, or 5G, allowing cable networks to seamlessly interact with smart grids, renewable energy systems, and urban infrastructure.

2. Key Technical Challenges in Embedded Development

Developing embedded systems for cable applications presents unique challenges:

- Harsh Environmental Conditions: Cables are often deployed underground, underwater, or in high-voltage environments. Embedded hardware must withstand extreme temperatures, moisture, and electromagnetic interference.

- Real-Time Processing: Fault detection and power distribution require millisecond-level response times. Engineers must optimize embedded firmware for low latency while managing power consumption.

- Interoperability: Cable networks interface with diverse third-party systems (e.g., substations, IoT devices). Ensuring compatibility across protocols demands rigorous testing and modular software design.

To overcome these hurdles, companies like CableTech have adopted ruggedized microcontrollers (e.g., STM32H7 series) and real-time operating systems (RTOS) such as FreeRTOS. Advanced signal processing algorithms, including Fast Fourier Transform (FFT) for noise filtering, are also critical for accurate data analysis.

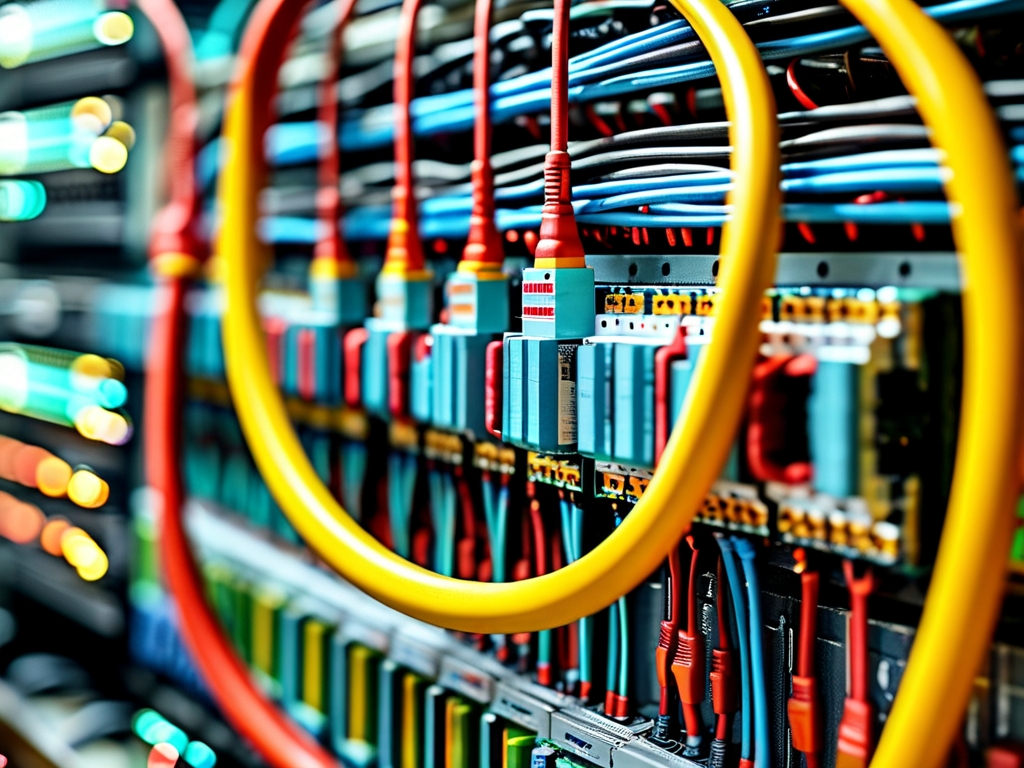

3. Case Study: Smart Grid Integration

A landmark project by CableTech illustrates the potential of embedded systems. The company developed an embedded monitoring solution for a national smart grid, deploying over 10,000 sensor nodes across 500 km of high-voltage cables. Each node featured:

- A 32-bit ARM Cortex-M7 processor for edge computing.

- Sub-1 GHz RF modules for long-range communication.

- Machine learning models to predict insulation breakdown.

This system reduced grid downtime by 40% and cut maintenance costs by $2.5 million annually. By analyzing historical load patterns, the embedded platform also optimized energy distribution during peak demand periods.

4. Future Trends: AI and Edge Computing

The next frontier for cable-focused embedded systems lies in AI-driven analytics and edge computing. Embedded FPGAs (Field-Programmable Gate Arrays) are now being used to deploy lightweight neural networks directly on cable sensors, enabling anomaly detection without cloud dependency. For example, AI models can differentiate between routine load spikes and arc-fault signatures, minimizing false alarms.

Moreover, the adoption of Time-Sensitive Networking (TSN) standards ensures synchronized data exchange across distributed embedded devices—a critical requirement for autonomous power grids and 5G backhaul networks.

5. Sustainability and Regulatory Compliance

Embedded systems also play a pivotal role in meeting sustainability goals. CableTech’s recent project incorporated energy-harvesting modules powered by electromagnetic induction from live cables, eliminating the need for battery replacements. Additionally, embedded firmware now includes compliance checks for international standards like IEC 61850 (power utility automation) and ISO 14001 (environmental management).

Embedded development is reshaping the cable industry, bridging the gap between legacy infrastructure and cutting-edge technology. As cable companies continue to innovate, the fusion of embedded systems, AI, and IIoT will unlock unprecedented levels of reliability, efficiency, and scalability. For engineers and stakeholders, staying ahead in this dynamic field requires a relentless focus on adaptive design, cross-disciplinary collaboration, and strategic investment in emerging technologies.