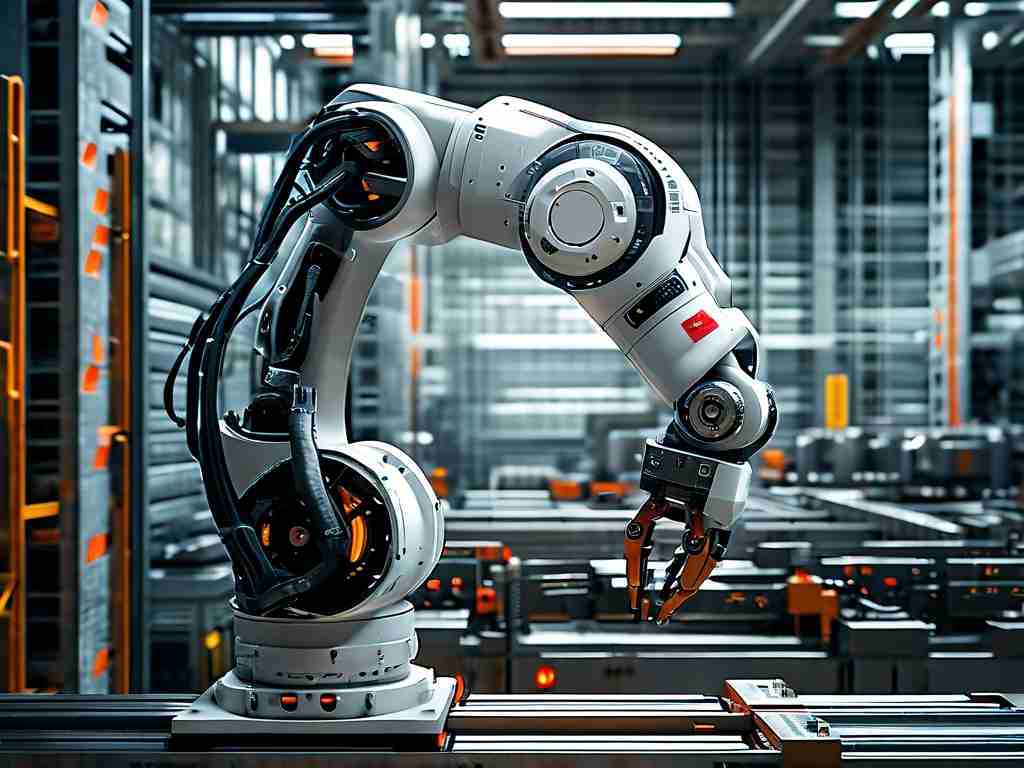

The relentless march of automation finds a powerful ally in robotic lift technology. Moving beyond simple horizontal movement, the ability of robots to precisely and reliably elevate and lower payloads, tools, or even their entire structure is fundamentally transforming operations across diverse sectors. This sophisticated capability, integrating mechanics, sensors, and intelligent control, unlocks new levels of efficiency, safety, and flexibility previously unattainable with static machinery or manual labor. Understanding the mechanisms and implications of robotic elevation is key to appreciating its revolutionary impact.

At the heart of robotic lift systems lie several core technologies working in concert. Linear actuators, whether electric (like ball screws or belt drives), hydraulic, or pneumatic, provide the primary force for vertical movement. These actuators are chosen based on the required speed, precision, force, and environmental conditions. For instance, hydraulic systems often excel in heavy lifting scenarios demanding immense force, while electric actuators offer superior precision and cleaner operation for electronics assembly. Complementing the actuator is a robust structural frame designed to handle the stresses of dynamic lifting and ensure stability, especially crucial when handling top-heavy or unbalanced loads. Precision guidance systems, typically employing linear rails or hardened shafts with recirculating ball bushings, guarantee smooth, wobble-free vertical travel, essential for tasks requiring micron-level accuracy.

Sensors form the nervous system of these lift mechanisms. Encoders provide real-time feedback on position, enabling closed-loop control for pinpoint accuracy. Load cells monitor the weight being lifted, critical for preventing overloads and enabling force-sensitive applications. Limit switches establish safe travel boundaries, while proximity sensors can detect the presence of objects or confirm successful engagement with a payload. The intelligence comes from sophisticated controllers – Programmable Logic Controllers (PLCs) or dedicated motion controllers. These processors interpret sensor data and execute complex motion profiles. They manage acceleration, deceleration, velocity, and final positioning, often coordinating the lift axis seamlessly with the robot's other movements (like rotation or extension). Advanced controllers can even compensate for variables like inertia or payload shift dynamically. Consider a simple Python snippet illustrating a basic lift command sequence for a controller (hypothetical API):

# Define target height in millimeters

target_height = 750

# Engage motor brake release (if applicable)

robot.axis['lift'].release_brake()

# Command lift to move to target height at 100 mm/s velocity

robot.axis['lift'].move_to_position(target_height, velocity=100)

# Wait until lift axis reports movement is complete

while robot.axis['lift'].is_moving:

time.sleep(0.1)

# Verify final position within tolerance

if abs(robot.axis['lift'].position - target_height) <= 2.0:

print("Lift positioned successfully at", robot.axis['lift'].position, "mm")

robot.axis['lift'].engage_brake() # Re-engage brake for holding

else:

print("Positioning error detected!")

The applications for robotic lift technology are vast and growing exponentially. In warehousing and logistics, robots equipped with lifting forks or platforms automate pallet handling, loading/unloading trucks, and retrieving items from multi-level storage racks with astonishing speed and precision, drastically reducing manual labor and injury risks. Manufacturing lines leverage lifting robots for precise part placement onto moving conveyors at different heights, inserting components into assemblies, operating machinery controls, or performing quality inspections at various vertical levels. The medical field benefits through robotic arms assisting surgeons with stable tool positioning or automating the transport of sensitive equipment and supplies between floors or departments. Construction and maintenance see potential in robots capable of lifting heavy materials to significant heights or providing stable platforms for inspection tools. Even agriculture utilizes lifting mechanisms on robots for tasks like selective harvesting from varying plant heights or precise pesticide application.

The advantages are compelling. Enhanced productivity stems from robots operating tirelessly at optimized speeds, handling repetitive lifting tasks far faster and more consistently than humans. Worker safety improves dramatically as employees are removed from hazardous lifting operations involving heavy weights, awkward postures, or dangerous environments (e.g., extreme temperatures, confined spaces). Robotic lifts deliver unparalleled precision and repeatability, crucial for delicate assembly tasks or processes requiring exact positioning. Their flexibility allows for easy reprogramming to handle different products or adapt to new layouts, a significant advantage over fixed automation. Furthermore, they optimize vertical space utilization within facilities, enabling high-density storage and production configurations.

However, implementing robotic lift systems presents challenges. The initial capital investment for sophisticated robots and integration can be substantial. Designing the system requires careful consideration of payload weight and center of gravity, required speed and precision, necessary range of motion, and the operating environment (cleanroom, washdown, explosive atmosphere). Robust safety systems, including physical guarding, light curtains, area scanners, and emergency stop circuits, are non-negotiable to protect personnel working near these powerful machines. Ensuring smooth coordination between the lift axis and other robot motions or external conveyor systems demands meticulous programming and synchronization. Maintenance requirements, though often less than manual labor costs, need to be factored in, including lubrication, belt tension checks, or potential actuator servicing. "The biggest hurdle isn't always the lift mechanism itself," notes an automation engineer specializing in material handling, "it's integrating it seamlessly into the existing workflow and ensuring the control system can react fast enough to real-world variability, like a slightly misaligned pallet. Sensor fusion and adaptive control algorithms are becoming essential."

The future trajectory of robotic lift technology points towards even greater sophistication. Integrating AI and machine learning will enable predictive maintenance, anticipating component wear before failure, and adaptive control, where the system learns optimal lifting paths or compensates for payload variations in real-time. The development of lighter, stronger materials will lead to more compact and energy-efficient lift systems capable of handling heavier loads. Enhanced sensor suites, including advanced 3D vision and tactile sensing, will grant robots greater situational awareness during complex lifting and placement operations, improving safety and reliability. Wireless power and communication systems will simplify integration and increase flexibility. We are also seeing the emergence of collaborative robots (cobots) with integrated lifting capabilities designed to work safely alongside humans on lighter assembly or kitting tasks. Finally, the rise of mobile manipulators – robots combining mobility (like AGVs) with dexterous arms and lift functions – promises truly flexible automation that can navigate factories or warehouses and perform complex handling tasks at various heights autonomously.

In , robotic lift technology is far more than a simple up-and-down mechanism. It represents a critical enabler of advanced automation, providing the crucial third dimension of movement. By mastering precise, reliable, and intelligent vertical motion, robots are overcoming physical limitations, unlocking new operational paradigms, and driving significant gains in efficiency, safety, and flexibility across countless industries. As core technologies continue to evolve and integrate with artificial intelligence, the reach and impact of robotic lift systems will only expand, solidifying their role as a foundational pillar of modern industrial and service robotics. The revolution is not just automated; it's vertically integrated.