The evolution of high-precision robotics control technology has redefined modern industrial and medical applications, enabling unprecedented accuracy in tasks ranging from microsurgery to semiconductor manufacturing. At its core, this technology integrates advanced algorithms, real-time feedback systems, and ultra-responsive actuators to achieve movements measured in micrometers. Unlike traditional robotics, which prioritize speed or payload capacity, high-precision systems focus on minimizing error margins while adapting dynamically to environmental variables like temperature fluctuations or mechanical wear.

One breakthrough driving this field is the adoption of adaptive neural networks. These AI-driven models analyze historical performance data to predict and compensate for potential inaccuracies. For instance, in aerospace component assembly, robots equipped with such systems adjust their grip strength and alignment in real time based on material hardness or surface irregularities—a capability impossible with preprogrammed workflows. This self-optimization reduces scrap rates by up to 40% in precision-dependent industries.

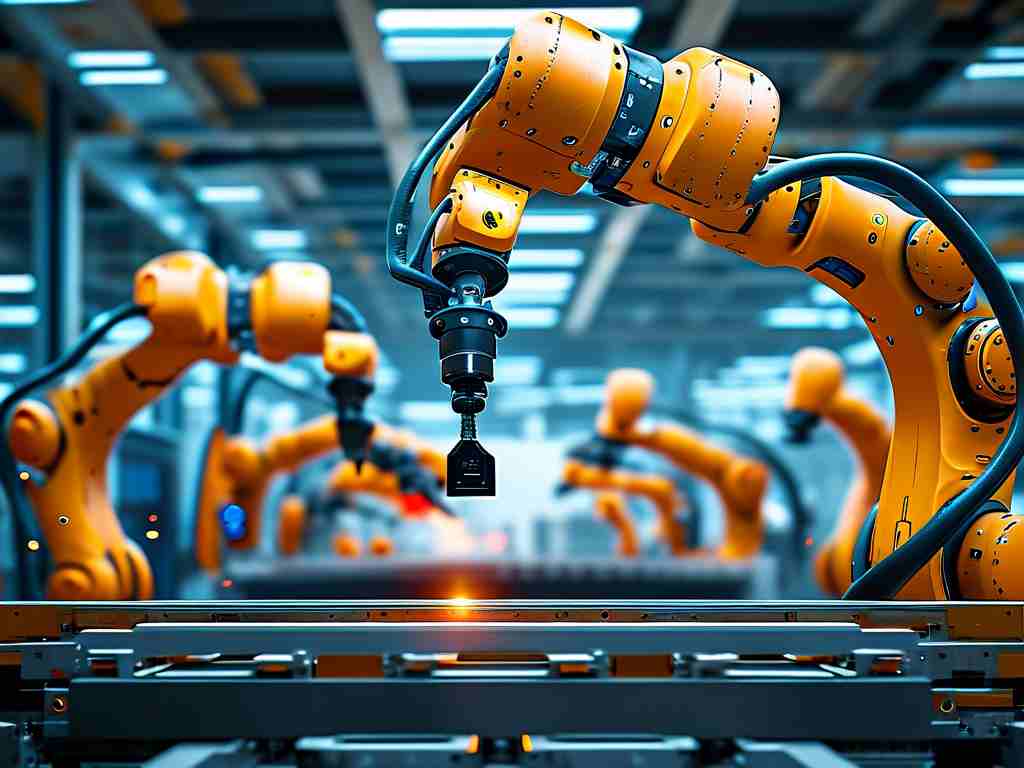

Another critical component is the use of piezoelectric actuators. These devices convert electrical signals into mechanical motion with nanoscale resolution, ideal for applications like optical lens polishing or circuit board soldering. When paired with laser-guided vision systems, robots can correct positional deviations within milliseconds. A notable case involves a German automotive manufacturer that reduced calibration errors by 92% after integrating piezoelectric-driven arms into their quality inspection lines.

However, achieving sub-micron precision demands overcoming significant challenges. Vibration damping remains a persistent issue, as even minor tremors from nearby machinery can disrupt delicate operations. Engineers address this through hybrid isolation systems combining passive dampers and active counter-vibration mechanisms. For example, semiconductor fabrication labs now deploy robotic arms mounted on magnetorheological fluid platforms that stiffen or soften in response to sensor-detected vibrations.

The role of edge computing cannot be overlooked. By processing sensor data locally rather than relying on cloud servers, high-precision robots achieve latency under 0.5 milliseconds—critical for synchronized multi-axis movements. A surgical robotics startup recently demonstrated this by enabling autonomous suturing at 200 stitches per minute with zero lag between haptic feedback and instrument response.

Despite these advancements, interoperability between different control systems poses barriers. Industry leaders are advocating for standardized communication protocols like OPC UA (Open Platform Communications Unified Architecture) to unify robotic ecosystems. Early adopters in the renewable energy sector report 30% faster integration times when deploying solar panel installation robots from multiple vendors.

Looking ahead, quantum sensors may push precision boundaries further. These devices exploit quantum entanglement phenomena to measure positional changes at the atomic level. While still experimental, prototypes have shown potential for revolutionizing nanotechnology assembly lines. Concurrently, ethical debates emerge about workforce displacement, though studies indicate that high-precision robotics often creates specialized maintenance and programming roles—up to 1.2 million new jobs globally by 2030.

In , high-precision robotics control technology is not merely an incremental improvement but a paradigm shift in automation. Its convergence with AI, advanced materials, and decentralized computing architectures will continue to unlock applications we are only beginning to imagine, from personalized pharmaceutical manufacturing to extraterrestrial construction projects.