Poland has emerged as a quiet yet formidable player in the global robotics landscape, blending technical ingenuity with practical applications. Unlike the flashy automation giants of Asia or the AI-driven systems from Silicon Valley, Polish robotics thrives on precision engineering, modular adaptability, and a strong alignment with industrial needs. This unique combination positions the country as a hub for specialized robotic solutions that prioritize functionality over hype.

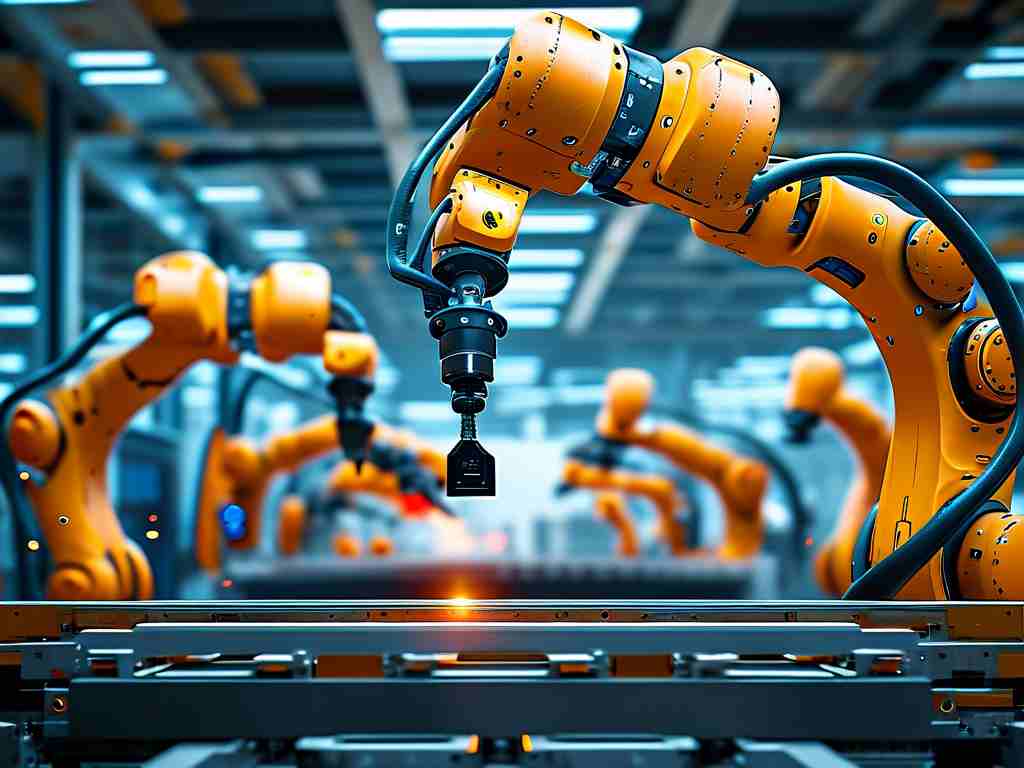

One defining characteristic of Polish robotics is its focus on precision mechanics. Companies like Transition Technologies PSC and Smart Solutions Group have developed robotic arms and assembly-line systems with micron-level accuracy. These systems are particularly valued in automotive manufacturing, where Polish-engineered robots handle tasks such as laser welding and component calibration. For instance, a recent collaboration between the Warsaw University of Technology and Fiat Chrysler Automobiles (FCA) produced a robotic vision system capable of detecting submillimeter defects in engine parts—a breakthrough that reduced production waste by 18% in pilot tests.

Another standout feature is adaptive modularity. Polish engineers design robots that can be reconfigured for multiple tasks without requiring complete overhauls. The startup RoboTech, based in Wrocław, exemplifies this approach. Their modular agricultural robots can switch between planting, watering, and harvesting modes by swapping tool attachments—a cost-effective solution for small-to-medium farms. This flexibility contrasts with rigid, single-purpose robots common in larger markets, making Polish designs particularly appealing to industries with fluctuating demands.

Poland’s robotics sector also emphasizes human-robot collaboration. Rather than replacing workers, many systems are built to augment human capabilities. Medical robotics is a prime example. The Gdansk-based company MediBot has pioneered lightweight exoskeletons that assist nurses in lifting patients, reducing physical strain and workplace injuries. Similarly, collaborative robots (cobots) from Kraków’s TechInvent integrate seamlessly into factory floors, working alongside technicians to handle repetitive tasks like screw tightening or quality checks. These innovations reflect a cultural emphasis on balancing automation with workforce sustainability.

A less obvious but critical strength lies in energy efficiency. Polish researchers have made strides in low-power robotics, driven partly by the country’s push toward sustainable manufacturing. The AGH University of Science and Technology in Kraków recently unveiled a solar-powered inspection robot for wind turbines, capable of operating for 72 hours on a single charge. Such advancements address growing industry demands for eco-friendly automation, particularly in sectors like renewable energy and logistics.

Education and government support further fuel these advancements. Poland’s network of technical universities—such as Poznań University of Technology and Łódź Institute of Mechatronics—prioritize hands-on robotics programs. Graduates often join local firms or launch startups, creating a self-sustaining talent pipeline. Meanwhile, initiatives like the National Center for Research and Development (NCBR) provide grants for projects bridging academia and industry, such as underwater drones for Baltic Sea environmental monitoring.

Despite these strengths, challenges persist. Limited venture capital and global brand recognition hinder scaling for many Polish robotics firms. However, partnerships with EU-funded programs like Horizon Europe are gradually opening doors to international markets. Companies like FlyTech, specializing in autonomous drones for precision agriculture, have begun exporting to Germany and Scandinavia, signaling growing confidence in Polish innovation.

Looking ahead, Poland’s robotics trajectory hinges on deepening niche expertise while fostering cross-industry collaborations. By staying rooted in practical problem-solving rather than chasing trends, the country is carving a distinct identity—one where robots aren’t just advanced, but authentically useful. As global industries increasingly value customization and sustainability, Poland’s blend of precision, adaptability, and human-centric design may well set a new benchmark for robotics excellence.