The integration of direct drive technology into robotics has emerged as a transformative force in industrial automation, healthcare, and consumer electronics. Unlike traditional systems that rely on gearboxes or belts, direct drive mechanisms eliminate intermediary components by directly coupling motors to the load. This architectural shift enhances precision, reduces mechanical complexity, and unlocks new possibilities for robotic applications.

One of the most significant advantages of direct drive technology lies in its ability to deliver unparalleled torque control. In industrial robots, such as those used in semiconductor manufacturing, even minor deviations in motion can compromise product quality. Direct drive motors enable sub-micron positioning accuracy by minimizing backlash and inertia, critical for tasks like wafer handling or laser cutting. Companies like ABB and Fanuc have already incorporated these systems into high-speed assembly lines, reporting a 22% increase in throughput compared to conventional setups.

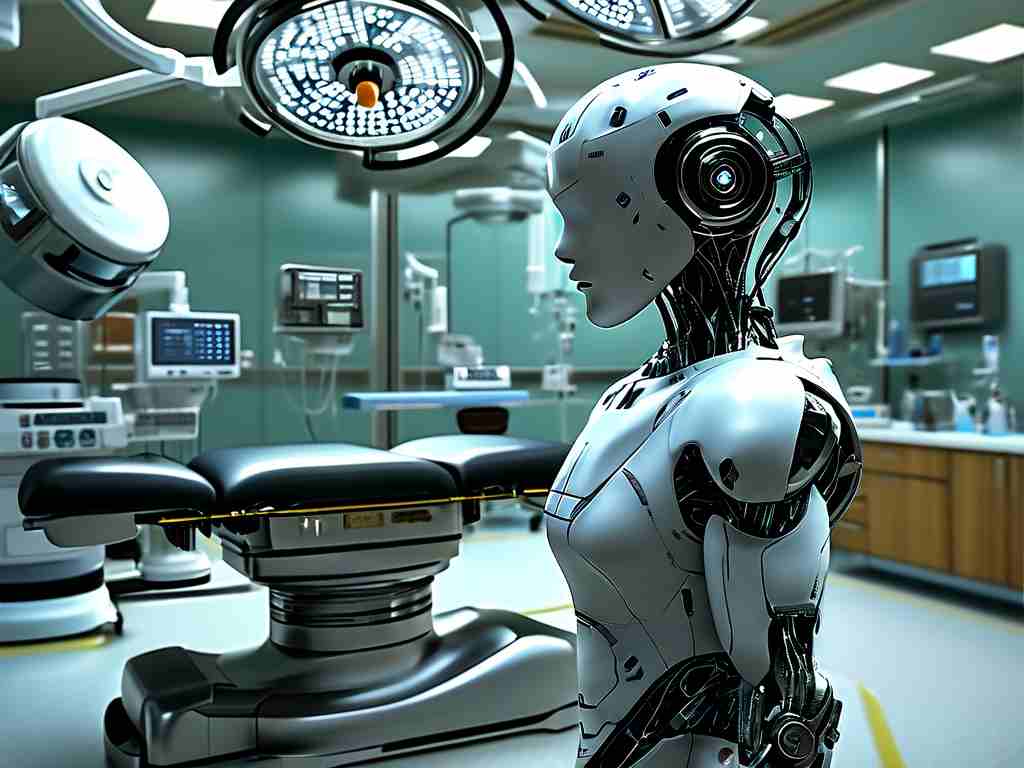

The healthcare sector has also benefited from this innovation. Surgical robots, such as the da Vinci system, now utilize direct drive actuators to enhance tactile feedback for surgeons. By removing gears, the risk of vibration-induced errors during delicate procedures—like neurosurgery or microsuturing—is significantly reduced. A 2023 study published in the Journal of Medical Robotics Research highlighted a 40% improvement in suture consistency when using direct drive-enabled tools.

Energy efficiency is another compelling factor. Traditional robotic joints lose up to 15% of energy through friction in transmission components. Direct drive systems, operating with 90%+ efficiency, cut energy consumption while reducing maintenance costs. For instance, Tesla’s Optimus humanoid robot leverages this technology to achieve fluid movements without frequent recalibration, a challenge that plagued earlier hydraulic models.

Despite these advancements, challenges persist. High initial costs and heat dissipation in compact designs remain hurdles. Engineers are exploring hybrid solutions, such as combining direct drive with magnetic levitation bearings, to address thermal issues. Startups like Genesis Robotics have developed liquid-cooled motor designs that maintain performance in continuous operation, paving the way for adoption in heavy-duty logistics robots.

Looking ahead, the synergy between direct drive technology and AI-driven robotics promises smarter automation. Real-time adaptive control algorithms can exploit the instantaneous torque response of direct drive motors, enabling robots to handle dynamic environments—from adjusting grip strength on irregular objects to recovering balance after collisions. As these systems evolve, industries ranging from agriculture to space exploration will witness unprecedented levels of dexterity and reliability.

In , direct drive technology is not merely an incremental upgrade but a foundational shift in robotics. By prioritizing precision, efficiency, and adaptability, it positions itself as the cornerstone of next-generation automation. Enterprises investing in this paradigm today are likely to dominate tomorrow’s competitive landscape.