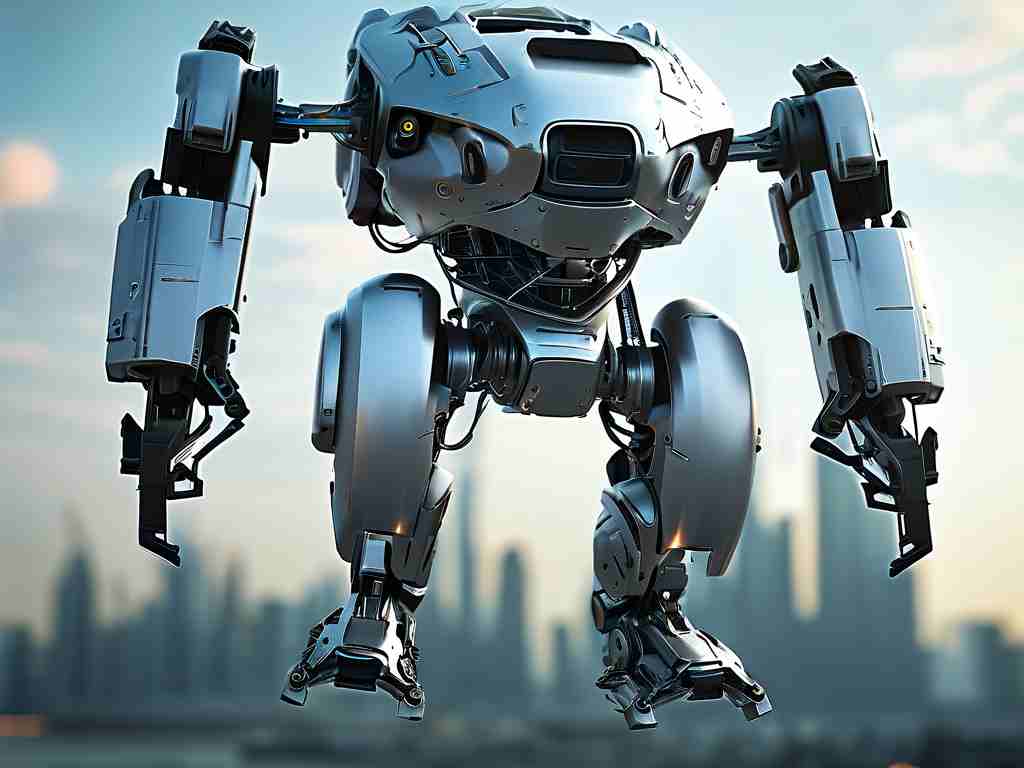

The realm of robotics is witnessing a paradigm shift with the advent of Hover-Adaptive Robotics Morphing Systems (HARMS). This frontier technology transcends the static designs of traditional robots, enabling them to dynamically alter their physical structure while actively maintaining a stable hover mid-air. It represents a sophisticated fusion of advanced materials science, real-time AI control, and precision aerodynamics, unlocking unprecedented capabilities for operations in complex, unstructured, or confined environments where conventional aerial platforms falter.

The Core Mechanics: Beyond Fixed Form

At the heart of HARMS lies the principle of in-flight morphological reconfiguration. Unlike drones or robots that operate with a fixed geometry, hover-adaptive robots incorporate:

- Modular or Continuously Deformable Structures: Utilizing shape-memory alloys (SMAs), electroactive polymers (EAPs), or intricate multi-link mechanisms with micro-actuators, these robots can bend, extend, contract, fold, or even reassemble components.

- Real-Time Stability Control: The true challenge isn't just changing shape, but doing so without losing lift or positional control. This demands ultra-responsive flight control algorithms that continuously recalculate thrust vectoring, center of gravity, and aerodynamic profiles during the morphing process. Advanced sensor fusion (IMUs, LiDAR, vision systems) feeds instantaneous data to these algorithms.

- Adaptive Propulsion Systems: Thrusters or rotors are often distributed and vectorable. As the robot morphs, thrust distribution and direction must be instantly adjusted across these distributed units to compensate for shifts in mass, drag, and lift surfaces. Think of it as a highly dynamic, multi-rotor system where the very frame connecting the rotors is fluid.

- Energy Management Intelligence: Morphing consumes significant energy. Sophisticated onboard AI not only manages the transformation path but also optimizes it for minimal energy expenditure while ensuring stability, often predicting the necessary adjustments milliseconds ahead. This involves complex path planning through a high-dimensional state space encompassing form, stability, and power constraints.

Pseudocode Snippet Illustrating Control Logic (Conceptual):

def main_control_loop():

current_shape = get_current_morphology()

target_shape = determine_target_shape(task, environment_scan) # AI-driven decision

hover_error = calculate_position_deviation()

while current_shape != target_shape and hover_error < max_tolerance:

# Calculate optimal morphing trajectory segment for stability

next_shape_segment, required_thrust_adjustments = calculate_safe_morph_step(current_shape, target_shape, hover_error, sensor_data)

# Execute morphing step via actuators (SMAs, motors, etc.)

execute_morph(next_shape_segment)

# Simultaneously adjust propulsion: vector thrust, redistribute power

adjust_propulsion_system(required_thrust_adjustments)

# Update state and sensors

current_shape = update_morphology_state()

hover_error = calculate_position_deviation()

sensor_data = acquire_new_sensor_data()

maintain_hover(target_shape) # Stabilize in new configuration

Unlocking Revolutionary Applications

The ability to hover and morph on-demand opens doors to scenarios previously deemed impractical or impossible:

- Search and Rescue in Confined/Collapsed Structures: A robot could enter a narrow crevice in a collapsed building in a compact, streamlined form. Upon locating survivors, it could morph to deploy sensors, communication relays, or even small life-support packages, all while hovering steadily in confined, unstable spaces inaccessible to rigid drones or humans.

- Precision Inspection and Maintenance: Inspecting complex machinery (like jet engines, power plant boilers) or intricate infrastructure (bridge undersides, pipeline interiors) often requires navigating tight spaces with varying geometries. A morphing hover-robot could adapt its shape to squeeze through access panels, unfold arms for detailed inspection or repair tools, and maintain position precisely near critical components without physical contact.

- Dynamic Payload Handling/Delivery: Imagine a logistics drone that morphs its body to create a protective cradle around an irregularly shaped, fragile package during flight, enhancing safety. Upon approach, it could extend precision grippers or landing struts tailored to the delivery site's constraints, all while hovering steadily.

- Adaptive Exploration in Extreme Environments: Exploring dense forests, caves, or other planetary surfaces (like Mars' rocky terrain or Venusian cloud layers) requires versatility. A morphing aerial robot could navigate tight tree canopies by becoming slender, transform into a stable observation platform over uneven ground, or reconfigure for different atmospheric densities or wind conditions.

- Swarm Coordination and Reconfiguration: Hover-adaptive robots in swarms could dynamically link together mid-air, forming larger, more capable structures (like bridges, shelters, or powerful communication arrays) or disassemble to perform distributed tasks, leveraging collective morphing for complex cooperative maneuvers.

Challenges and the Path Forward

Despite its immense promise, HARMS faces significant hurdles:

- Energy Density and Efficiency: Morphing actuators and continuous stability adjustments are power-hungry. Breakthroughs in battery technology or novel onboard power generation are crucial for extended missions.

- Control Complexity and Robustness: Ensuring stability during rapid, complex morphing sequences, especially under dynamic external disturbances (wind gusts, collisions), requires incredibly robust and fail-safe control systems. Verifying the safety of these systems is paramount.

- Material Durability and Fatigue: Actively morphing structures undergo significant mechanical stress. Developing lightweight, high-strength materials resistant to fatigue over thousands of transformation cycles is essential for practical deployment.

- Sensor Integration and Miniaturization: Packing all necessary sensors (for environment perception, proprioception, and precise positioning) into a morphing body without hindering its movement or adding excessive weight remains a challenge.

- Computational Burden: Real-time calculation of optimal morphing paths and corresponding propulsion adjustments demands immense onboard processing power within strict size, weight, and power (SWaP) constraints. Edge AI and neuromorphic computing offer potential solutions.

: The Shape of Things to Come

Robot Hovering Deformation Technology is not merely an incremental improvement; it's a foundational shift towards truly adaptable aerial machines. By mastering the delicate interplay between dynamic physical form and stable flight control, HARMS paves the way for robots that can fluidly interact with and navigate the complexities of the real world in ways previously confined to science fiction. While challenges in energy, control, and materials persist, the rapid convergence of enabling technologies suggests that the era of robots capable of redefining their shape mid-hover is dawning. These systems promise to revolutionize fields from disaster response and infrastructure management to logistics and exploration, fundamentally altering how we perceive and utilize robotic capabilities in the air and beyond. The future of robotics is not just flying; it's flying and transforming.