The rapid evolution of industrial automation has transformed manufacturing, healthcare, logistics, and countless other sectors. At the forefront of this revolution is KUKA Robotics, a global leader in robotic systems and intelligent automation solutions. With a legacy spanning over a century, KUKA has pioneered innovations that redefine efficiency, precision, and scalability in industrial processes. This article explores the diverse applications of KUKA robot technology, its impact on industries, and the future trends shaping this dynamic field.

KUKA Robotics: A Brief Overview

Founded in 1898 in Germany, KUKA initially focused on welding and lighting systems before transitioning to robotics in the 1970s. Today, the company is renowned for its industrial robots, collaborative robots (cobots), and integrated automation systems. KUKA’s product portfolio includes the KR QUANTEC series for heavy payloads, the LBR iiwa cobot for sensitive tasks, and mobile platforms like the KMR series. These systems are driven by advanced software, such as KUKA.Connect for data analytics and smartFactory for seamless IoT integration.

Applications in Manufacturing

-

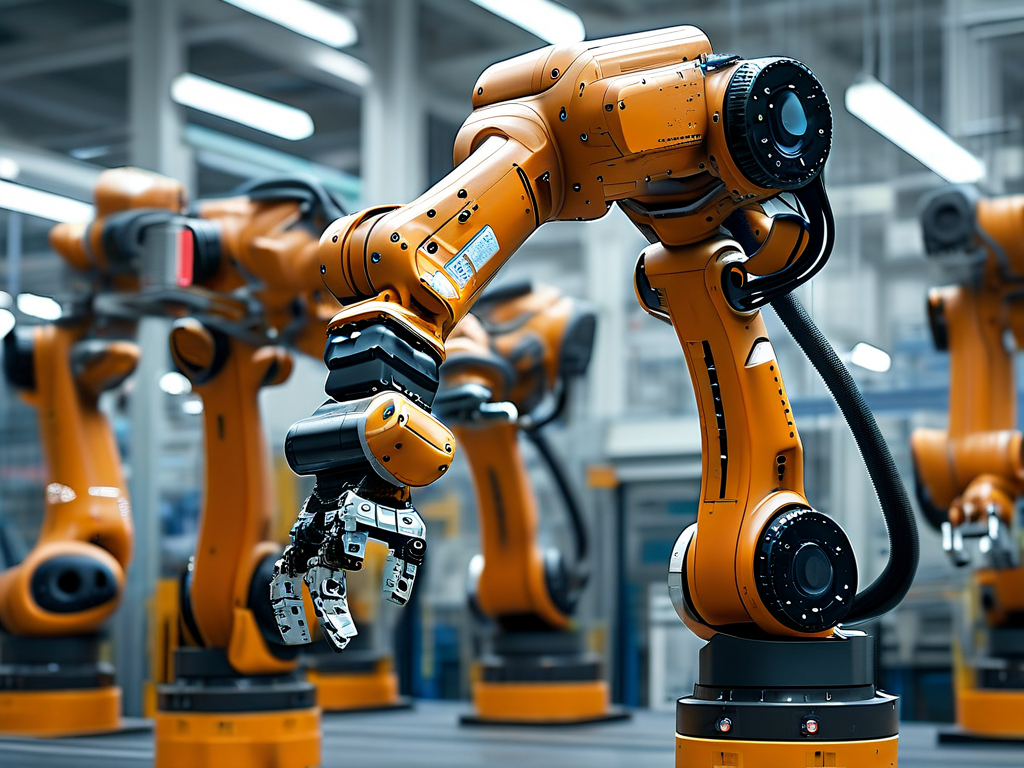

Automotive Industry:

KUKA robots are synonymous with automotive manufacturing. From welding car bodies to installing windshields, their precision reduces error rates and accelerates production. For instance, BMW’s factories utilize KUKA’s KR 1000 Titan, a six-axis robot capable of handling 1,000 kg payloads, to assemble chassis components. This not only enhances speed but also ensures worker safety in hazardous environments. -

Electronics and Consumer Goods:

In electronics manufacturing, KUKA’s SCARA robots excel at high-speed pick-and-place tasks. Companies like Samsung deploy these robots to assemble circuit boards with micron-level accuracy. Similarly, cobots like the LBR iiwa assist in packaging consumer goods, adapting dynamically to varying product sizes without manual reprogramming. -

Metal and Plastics Processing:

KUKA’s welding and cutting robots dominate metal fabrication. Their KR CYBERTECH series uses AI-powered vision systems to detect weld seams in real time, optimizing energy use and material waste. In plastics, KUKA robots manage injection molding and post-processing, ensuring consistent quality for products ranging from medical devices to automotive interiors.

Healthcare and Medical Innovations

KUKA’s reach extends beyond factories. In healthcare, their robots assist surgeons in minimally invasive procedures. The KUKA Medical Robot, certified for operating rooms, enables precise incisions and reduces patient recovery times. During the COVID-19 pandemic, KUKA robots were repurposed to automate PCR testing, processing thousands of samples daily with zero contamination risk.

Logistics and Warehousing

E-commerce giants like Amazon rely on KUKA’s mobile robots to streamline warehouse operations. The KMR iiwa combines autonomous navigation with robotic arms to sort, pick, and pack orders. In ports, KUKA’s automated guided vehicles (AGVs) load containers onto ships, cutting turnaround times by 30%. These solutions address labor shortages while boosting throughput.

Emerging Trends and Future Prospects

-

AI and Machine Learning Integration:

KUKA is integrating AI into its systems to enable predictive maintenance and adaptive workflows. For example, their robots now analyze vibration data to predict motor failures weeks in advance, minimizing downtime. -

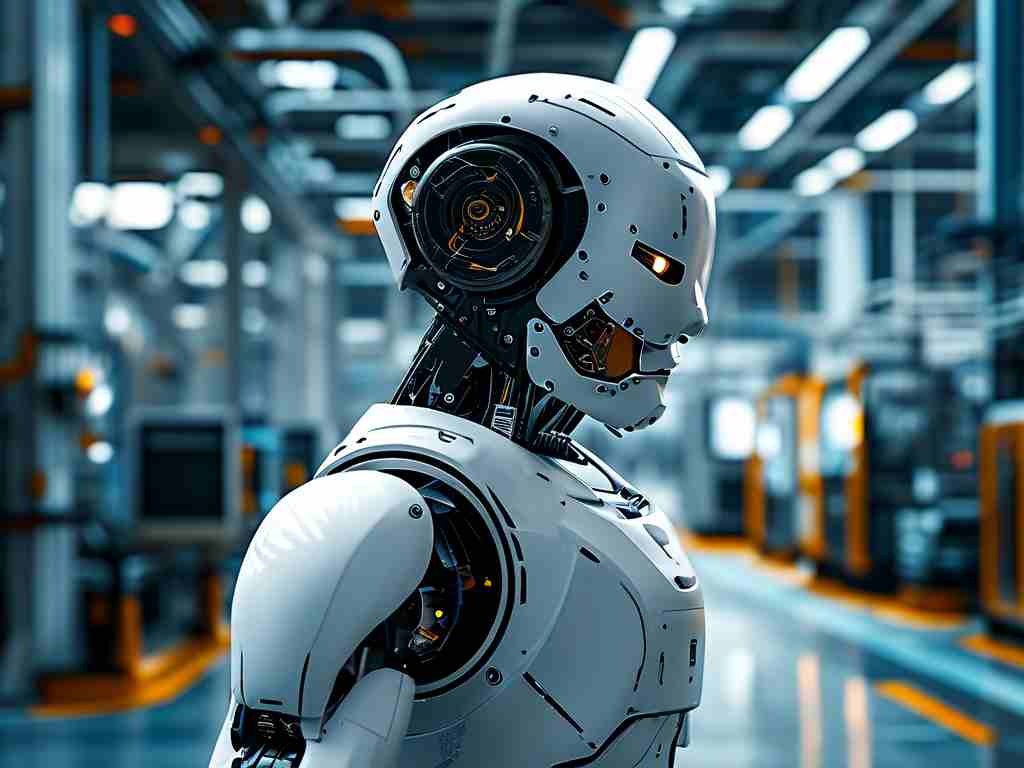

Human-Robot Collaboration:

The rise of cobots like the LBR iiwa reflects a shift toward human-robot teamwork. These robots use force-sensing technology to work safely alongside humans, handling repetitive tasks while employees focus on complex decision-making. -

Sustainable Automation:

KUKA is committed to green manufacturing. Their energy-efficient robots reduce power consumption by up to 40%, while recycling-oriented designs ensure 90% of robot components are reusable.

Challenges and Considerations

Despite its advantages, KUKA’s technology faces challenges. High upfront costs and the need for skilled technicians limit accessibility for small businesses. Additionally, cybersecurity risks in IoT-enabled systems demand robust safeguards. KUKA addresses these issues through subscription-based leasing models and partnerships with vocational training institutes.

KUKA Robotics continues to push the boundaries of automation, delivering solutions that enhance productivity, safety, and sustainability. As industries embrace Industry 4.0, KUKA’s innovations in AI, cobotics, and green technology will play a pivotal role in shaping the factories and workplaces of tomorrow. By balancing technological advancement with ethical and practical considerations, KUKA exemplifies the transformative potential of robotics in the 21st century.