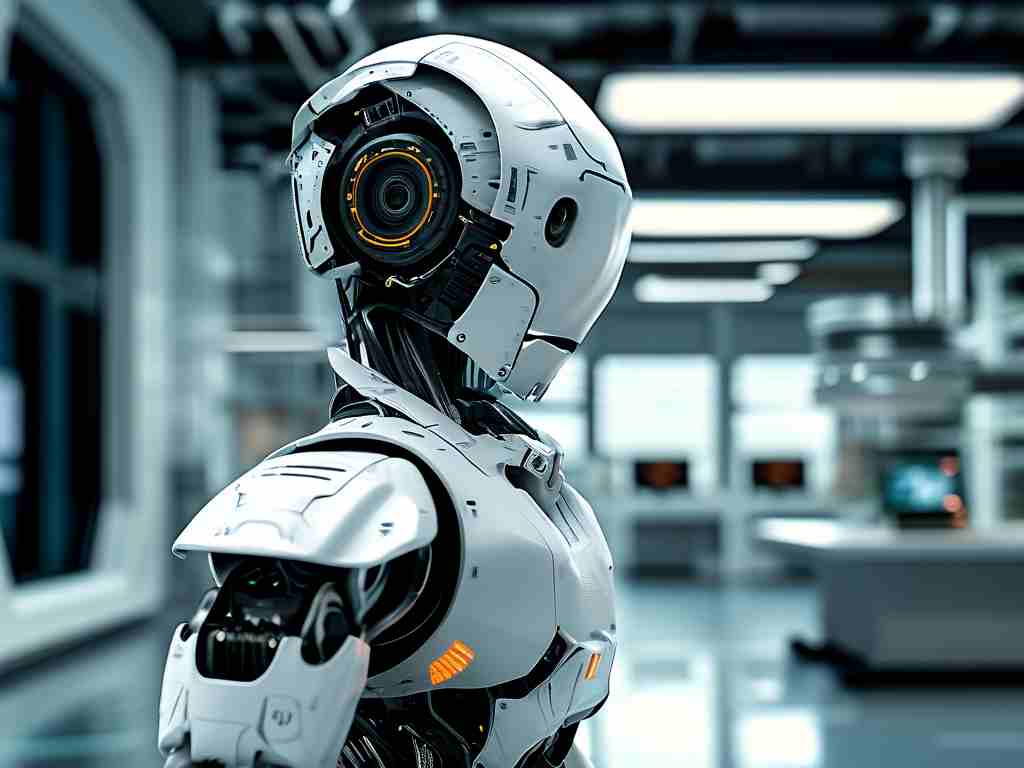

When Elon Musk unveiled Tesla’s Optimus humanoid robot prototype in 2022, it marked a bold leap into a future where machines don’t just assist humans—they mirror them. Combining Tesla’s expertise in electric vehicles, AI, and energy systems, the project redefines what humanoid robotics could achieve in industrial and domestic settings. But how does Optimus differ from decades of robotics research, and why might it succeed where others stalled?

The Fusion of Automotive and Robotic Engineering

Tesla’s approach to humanoid robots borrows heavily from its automotive innovations. The Optimus prototype integrates autonomous driving algorithms originally designed for Tesla’s Full Self-Driving (FSD) system. These algorithms enable real-time environmental mapping and decision-making, allowing the robot to navigate dynamic spaces like warehouses or homes without predefined paths. For instance, Optimus uses the same camera-based vision system as Tesla vehicles, processing 360-degree inputs to avoid collisions and adapt to obstacles—a stark contrast to traditional robots reliant on structured environments.

Another critical crossover is battery technology. Leveraging Tesla’s advancements in lithium-ion energy density, Optimus operates for up to 8 hours on a single charge. This endurance addresses a longstanding barrier in humanoid robotics: power constraints that limit mobility and functionality.

Redefining Labor Economics

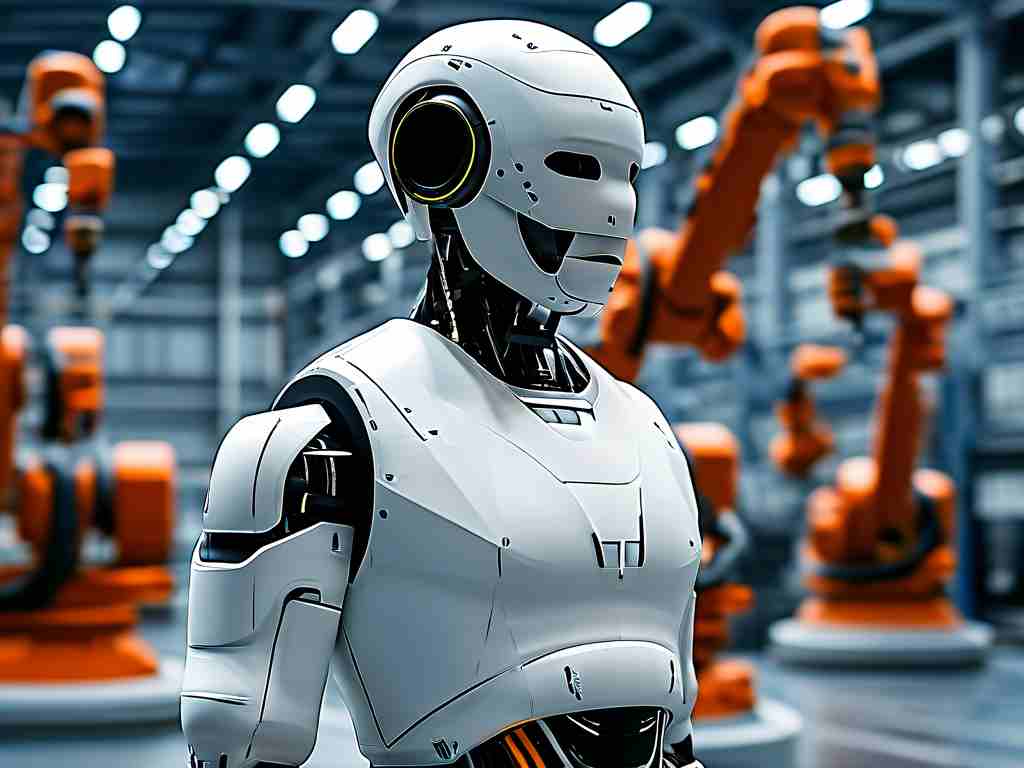

Humanoid robots have long been dismissed as impractical due to high costs and mechanical fragility. Tesla, however, aims to disrupt this narrative by scaling production using its Gigafactory infrastructure. Musk claims Optimus could eventually cost “less than $20,000”—a fraction of the $100,000+ price tag of research-focused humanoids like Boston Dynamics’ Atlas. If achieved, this would democratize robotics for small businesses and households.

Early pilot programs hint at transformative applications. In Tesla’s Fremont factory, pre-production Optimus units perform repetitive tasks like sorting components and transporting materials. Unlike single-purpose robotic arms, Optimus’s generalized design allows it to switch between roles—from quality inspection to logistics—with software updates rather than hardware reconfiguration.

Ethical and Technical Hurdles

Despite progress, challenges persist. Balancing bipedal mobility with energy efficiency remains a thorny issue. While Optimus walks at 5 mph—slower than human averages—its stability on uneven surfaces still lags behind wheeled or quadruped robots. Tesla’s team is experimenting with hybrid movement models, blending walking and rolling for complex terrains.

Privacy concerns also loom. Equipped with cameras and microphones, humanoid robots in homes or workplaces could raise surveillance-related objections. Tesla has countered by emphasizing on-device data processing, ensuring sensor data isn’t uploaded to external servers unless explicitly permitted.

The Road Ahead

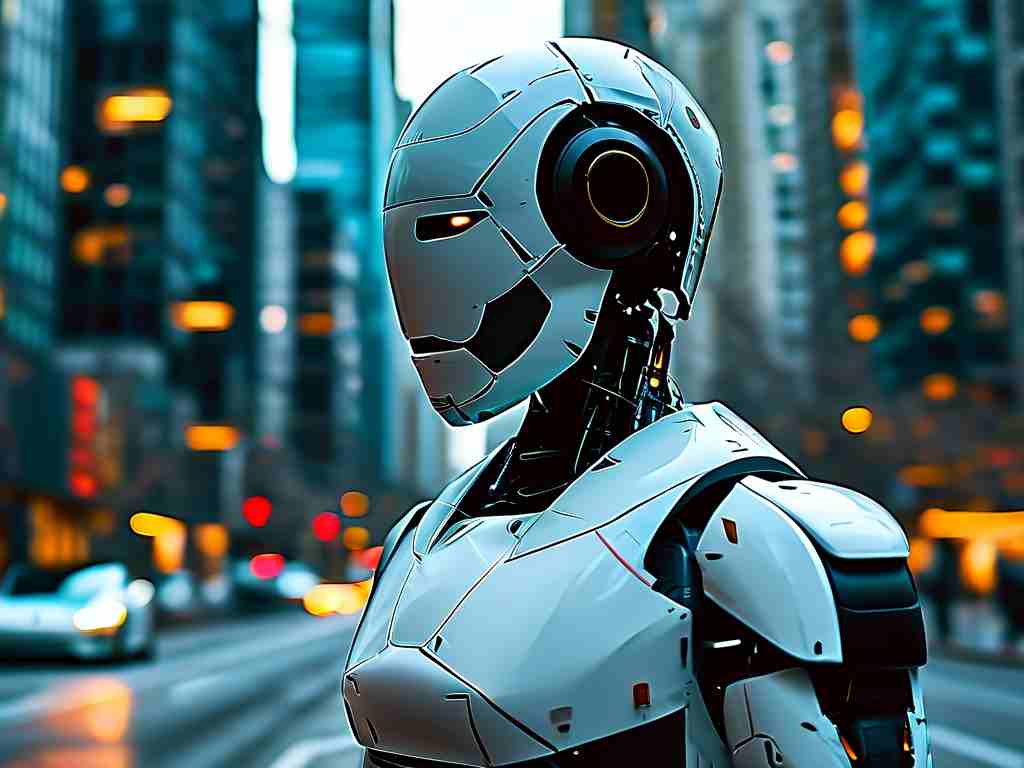

Analysts predict Tesla’s robotics venture could unlock a $150 billion market by 2035. Competitors like Hyundai (via Boston Dynamics) and Xiaomi are accelerating their own humanoid projects, but Tesla’s vertical integration—from chips to batteries—gives it a unique edge. The upcoming Optimus Gen 2, rumored to feature tactile sensors and improved joint actuators, may narrow the gap between experimental prototypes and commercial viability.

What’s certain is that Tesla isn’t just building robots; it’s crafting a blueprint for human-machine coexistence. As Optimus evolves, it could reshape industries from healthcare to construction—and redefine how humanity perceives its relationship with technology.