In modern engineering systems, the term "distributed electronic control architecture" has become a cornerstone for advanced technological implementations. This framework revolutionizes how complex systems operate by decentralizing computational tasks across multiple interconnected modules rather than relying on a single centralized unit. Let’s explore its principles, advantages, and real-world applications.

Core Principles

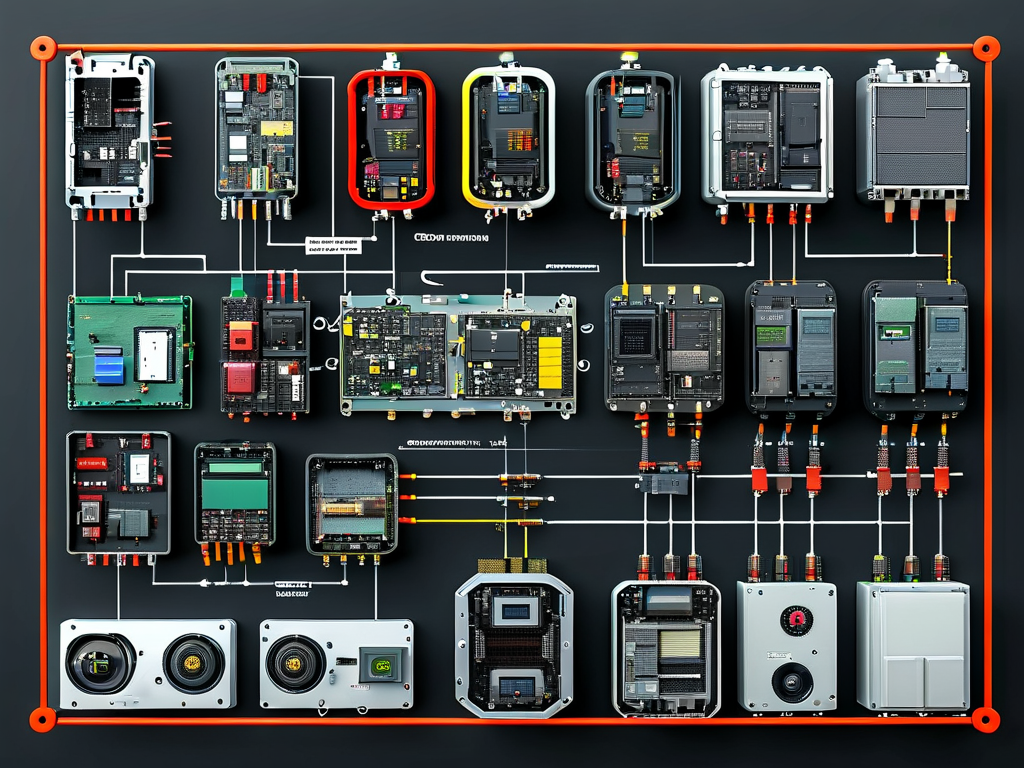

A distributed electronic control architecture divides control responsibilities among spatially separated nodes, each equipped with localized processing power and sensors. These nodes communicate through high-speed networks like CAN (Controller Area Network) or Ethernet, enabling coordinated operations without centralized bottlenecks. For example, in electric vehicles, motor control, battery management, and infotainment systems operate as independent yet synchronized units.

This design contrasts with traditional centralized systems where a single Electronic Control Unit (ECU) handles all computations. Centralized approaches often face limitations in scalability and fault tolerance—if the main ECU fails, the entire system collapses. Distributed architectures mitigate this risk by isolating failures to specific modules while maintaining overall functionality.

Technical Components

- Smart Nodes: These are embedded controllers with dedicated microprocessors, tailored to manage specific tasks. In industrial automation, a node might control robotic arm movements while another monitors temperature sensors.

- Communication Protocols: Networks like FlexRay or LIN (Local Interconnect Network) ensure low-latency data exchange. For instance, automotive systems use CAN FD (Flexible Data-Rate) to transmit critical safety data between brakes and steering systems.

- Central Coordination Layer: While processing is decentralized, a lightweight central module often oversees system-wide parameters. Consider smart grids: substations autonomously adjust power distribution while a central server monitors grid stability.

Industry Applications

Automotive Sector

Electric vehicles (EVs) heavily rely on distributed architectures. Tesla’s battery management system assigns individual control modules to each battery pack, optimizing charge cycles and thermal management. Similarly, advanced driver-assistance systems (ADAS) distribute processing between cameras, radar, and LiDAR units to enable real-time decision-making.

Industrial Automation

Factories deploy distributed control to enhance production line flexibility. ABB’s robotic systems, for example, use independent controllers for each robotic arm, allowing simultaneous adjustments without halting entire workflows. This setup reduces downtime and improves fault isolation.

Consumer Electronics

Smart home ecosystems exemplify distributed control. Devices like Philips Hue lights or Nest thermostats operate autonomously but synchronize via cloud-based or local hubs. This architecture ensures that a router outage doesn’t disable all connected devices.

Advantages Over Centralized Systems

- Scalability: Adding new modules doesn’t require overhauling existing infrastructure. A smart factory can integrate additional robots by simply connecting new nodes to the network.

- Fault Tolerance: If a sensor fails in a distributed HVAC system, other nodes compensate by recalculating airflow patterns, maintaining climate control.

- Real-Time Responsiveness: Autonomous vehicles process lidar data locally at each sensor node, reducing latency compared to sending raw data to a central computer.

Challenges and Solutions

Despite its benefits, this architecture introduces complexities. Network latency and synchronization issues can arise in time-sensitive applications. Engineers address this by implementing time-triggered protocols like TTEthernet, which prioritizes critical data packets. Security is another concern—decentralized nodes expand attack surfaces. Solutions include hardware-based encryption in NXP’s automotive microcontrollers and blockchain-style validation for industrial IoT devices.

Future Trends

The integration of edge computing and AI will further enhance distributed systems. For instance, NVIDIA’s DRIVE platform embeds AI processors in each vehicle sensor, enabling localized object detection. Similarly, 5G’s ultra-reliable low-latency communication (URLLC) will support real-time coordination in smart cities, from traffic lights to drone delivery networks.

In summary, distributed electronic control architecture represents a paradigm shift in system design, balancing autonomy with collaboration. Its adaptability makes it indispensable across industries, paving the way for smarter, more resilient technologies.