In the rapidly evolving landscape of modern engineering and technology, the term Electrically Controlled Distributed Architecture (ECDA) has gained significant traction, particularly in industries such as automotive manufacturing, aerospace, and industrial automation. But what exactly does it mean? This article delves into the definition, components, applications, and implications of ECDA, offering a comprehensive understanding of its role in shaping next-generation systems.

Defining Electrically Controlled Distributed Architecture

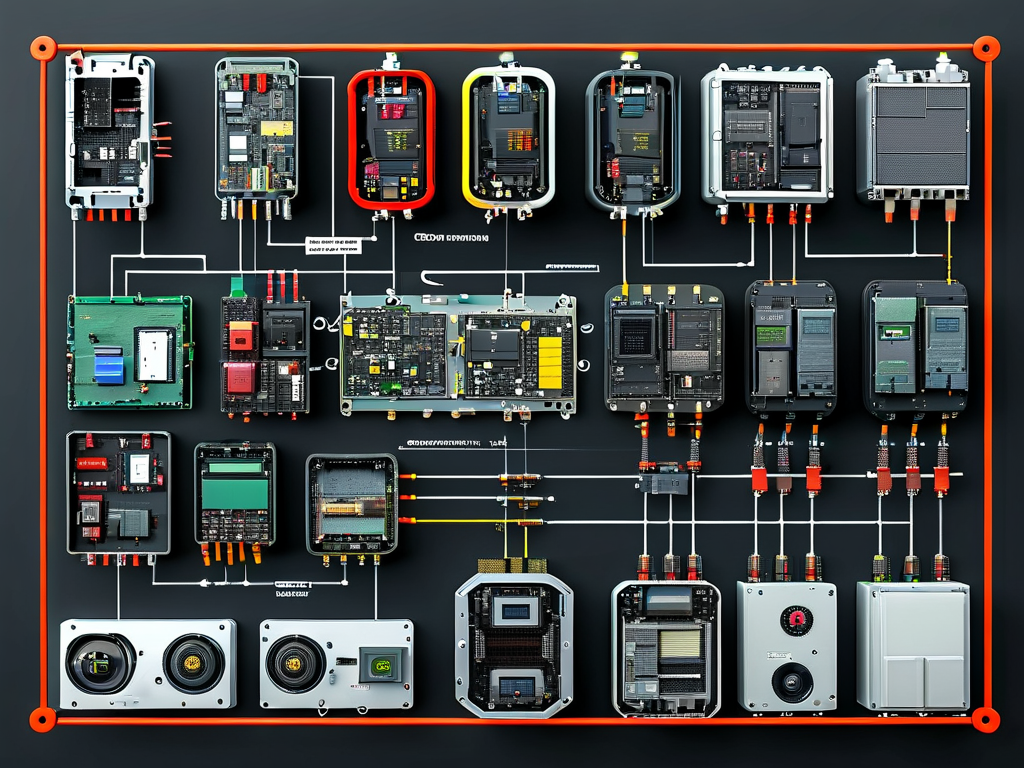

Electrically Controlled Distributed Architecture refers to a system design framework where control functions are decentralized across multiple interconnected electronic control units (ECUs) rather than relying on a single centralized controller. This architecture leverages advanced communication protocols-such as Controller Area Network (CAN), Ethernet, or FlexRay-to enable real-time data exchange between distributed components. By dispersing computational and decision-making tasks, ECDA enhances system flexibility, scalability, and fault tolerance.

Key Components of ECDA

- Distributed ECUs: These are modular electronic units responsible for specific tasks, such as managing a vehicle's braking system, engine performance, or infotainment. Each ECU operates independently but collaborates with others via a shared network.

- Communication Networks: High-speed buses like CAN or Ethernet form the backbone of ECDA, ensuring seamless interaction between ECUs. These networks prioritize data integrity and low latency.

- Sensors and Actuators: These components collect real-time data (e.g., temperature, pressure) and execute physical actions (e.g., adjusting throttle position), feeding information back to ECUs for analysis.

- Central Gateway: While ECDA emphasizes decentralization, a central gateway often acts as a mediator for critical functions like cybersecurity or over-the-air (OTA) updates.

Applications of ECDA

1. Automotive Industry

ECDA is revolutionizing automotive design. Modern vehicles, especially electric and autonomous cars, rely on distributed architectures to manage complex subsystems. For example:

- Advanced Driver-Assistance Systems (ADAS): Cameras, LiDAR, and radar sensors work with distributed ECUs to enable features like adaptive cruise control or lane-keeping.

- Battery Management Systems (BMS): In electric vehicles, distributed controllers monitor individual battery cells, optimizing performance and safety.

2. Industrial Automation

Factories employing ECDA can dynamically reconfigure production lines. Robots, conveyor belts, and quality-control systems operate as independent nodes, reducing downtime and improving efficiency.

3. Aerospace

Aircraft systems use ECDA to enhance reliability. Flight control, navigation, and engine management are handled by redundant ECUs, ensuring safety even if one unit fails.

Advantages of ECDA

- Scalability: Adding new functionalities (e.g., a new sensor or software feature) requires minimal disruption to the existing system.

- Fault Tolerance: If one ECU fails, others can compensate, preventing total system shutdown.

- Energy Efficiency: Localized processing reduces the need for high-power central processors.

- Cost-Effectiveness: Modular design simplifies maintenance and upgrades.

Challenges and Considerations

Despite its benefits, ECDA introduces complexities:

- Network Security: Distributed systems are vulnerable to cyberattacks. Robust encryption and intrusion detection mechanisms are essential.

- Synchronization: Ensuring real-time coordination between ECUs demands precise timing protocols.

- Compatibility: Integrating legacy systems with modern ECDA frameworks can be technically challenging.

Case Study: ECDA in Electric Vehicles

Tesla's electric vehicles exemplify ECDA in action. Their cars use dozens of ECUs to manage everything from battery temperature to autonomous driving. For instance, the Autopilot system relies on a distributed network of cameras and sensors, each processed by dedicated ECUs before aggregating data for decision-making. This architecture allows Tesla to push software updates that enhance performance without hardware modifications.

Future Trends

As industries embrace connectivity and automation, ECDA will evolve in three key directions:

- Edge Computing Integration: Processing data closer to the source (e.g., within sensors) will reduce latency.

- AI-Driven ECUs: Machine learning algorithms will enable ECUs to predict failures and optimize operations autonomously.

- Standardization: Industry-wide protocols (e.g., AUTOSAR in automotive) will streamline ECDA adoption.

Electrically Controlled Distributed Architecture represents a paradigm shift in system design, balancing decentralization with intelligent coordination. By empowering individual components to act as semi-autonomous agents, ECDA paves the way for smarter, safer, and more adaptable technologies. As industries continue to innovate, understanding and leveraging this architecture will be critical to staying competitive in the digital age.