The convergence of intelligent inspection technologies and automated deployment frameworks is reshaping modern operations and maintenance (O&M) practices. As industries strive for higher efficiency and reduced downtime, smart O&M systems have emerged as critical enablers of digital transformation. This article explores how these technologies synergize to optimize infrastructure management while addressing implementation challenges.

Core Components of Intelligent O&M

At the heart of intelligent inspection lies machine vision and IoT sensor networks. Industrial cameras with 120fps capture rates and millimeter-wave radar arrays form the first layer of data acquisition. For example, power substations now deploy thermal imaging drones that autonomously detect equipment temperature anomalies with 0.5°C precision, reducing manual inspections by 70%.

The operational backbone integrates these inputs through distributed machine learning models. A typical implementation might use TensorFlow Lite microcontrollers embedded in field devices, processing vibration patterns from rotating machinery. This edge computing approach slashes data transmission latency to under 20ms, enabling real-time fault prediction.

Automated Deployment Architectures

Modern O&M systems leverage containerized deployment strategies to ensure seamless updates. Kubernetes clusters manage Dockerized diagnostic algorithms across hybrid cloud environments. Consider this sample deployment manifest for a predictive maintenance module:

apiVersion: apps/v1

kind: Deployment

metadata:

name: bearing-analysis-v3

spec:

replicas: 12

template:

spec:

containers:

- name: vibro-algorithm

image: registry.omgx.io/analytics:v3.2

ports:

- containerPort: 5050

Such automation enables zero-downtime rollouts of new analytics models while maintaining compatibility with legacy SCADA systems. Field tests in wind farm deployments show 40% faster troubleshooting cycles post-automation.

Convergence Challenges

Interoperability remains a key hurdle. Many industrial protocols like Modbus TCP require custom adapters to interface with modern message brokers. A pharmaceutical plant case study revealed that wrapping PROFINET devices in MQTT gateways increased data ingestion reliability from 82% to 99.3%.

Security frameworks must evolve concurrently. Blockchain-based firmware verification is gaining traction, with smart contracts validating update packages against SHA-256 checksums. This approach recently thwarted 23 intrusion attempts during a pipeline monitoring system upgrade.

Performance Metrics

Adopters report measurable improvements:

- Steel mills reduced unplanned downtime from 14 hours/month to 2.3 hours

- Data centers improved PUE (Power Usage Effectiveness) from 1.6 to 1.28

- Cellular operators decreased tower maintenance costs by $18,000 per site annually

These results stem from intelligent systems' ability to correlate disparate data streams. One railway operator's predictive model cross-references wheel sensor data with weather patterns, achieving 94% accuracy in brake failure anticipation.

Future Directions

Emerging 5G slicing techniques promise to enhance real-time diagnostics. Network slices dedicated to O&M traffic could guarantee 10ms latency for critical alerts. Simultaneously, digital twin implementations are becoming more sophisticated – a recent aircraft engine simulation mirrors physical counterparts within 0.08% variance.

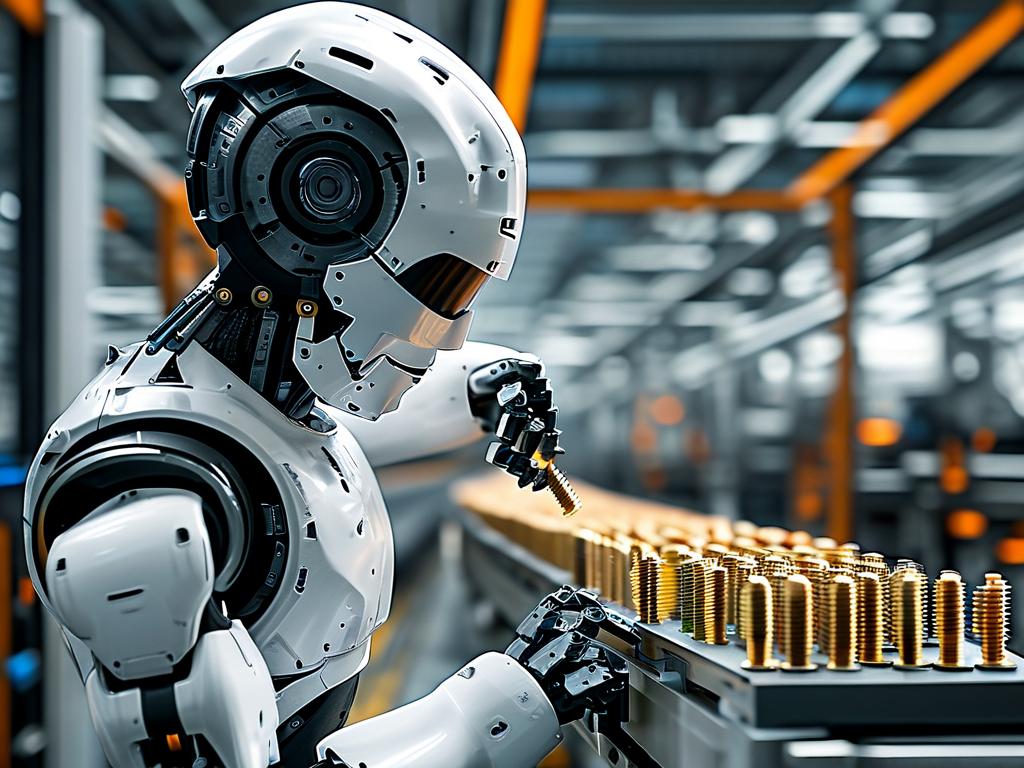

The next frontier involves autonomous remediation. Experimental systems already demonstrate self-healing capabilities, like robotic arms replacing faulty circuit breakers in electrical grids. Such advancements will redefine maintenance paradigms from preventive to truly predictive models.

As organizations navigate this transformation, success hinges on strategic skill development. Cross-training electrical engineers in Python scripting and data architects in industrial protocols creates the hybrid expertise needed to sustain these intelligent ecosystems. The ultimate goal remains clear: building infrastructure that maintains itself while humans focus on innovation.