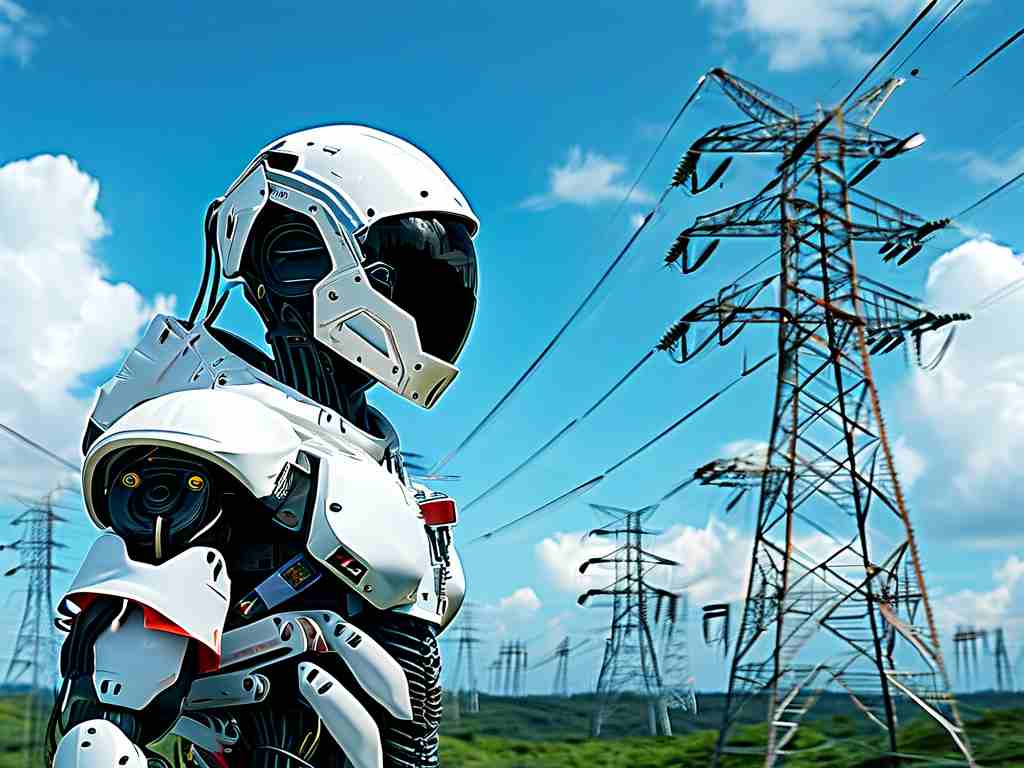

The integration of robotics into power grid inspection has revolutionized the maintenance and monitoring of electrical infrastructure. As energy demands grow and grids become more complex, traditional manual inspection methods struggle to keep pace with safety and efficiency requirements. This shift toward automation, driven by advancements in robotics and artificial intelligence, addresses critical challenges in the energy sector while paving the way for smarter, more resilient power systems.

Technological Foundations of Grid Inspection Robots

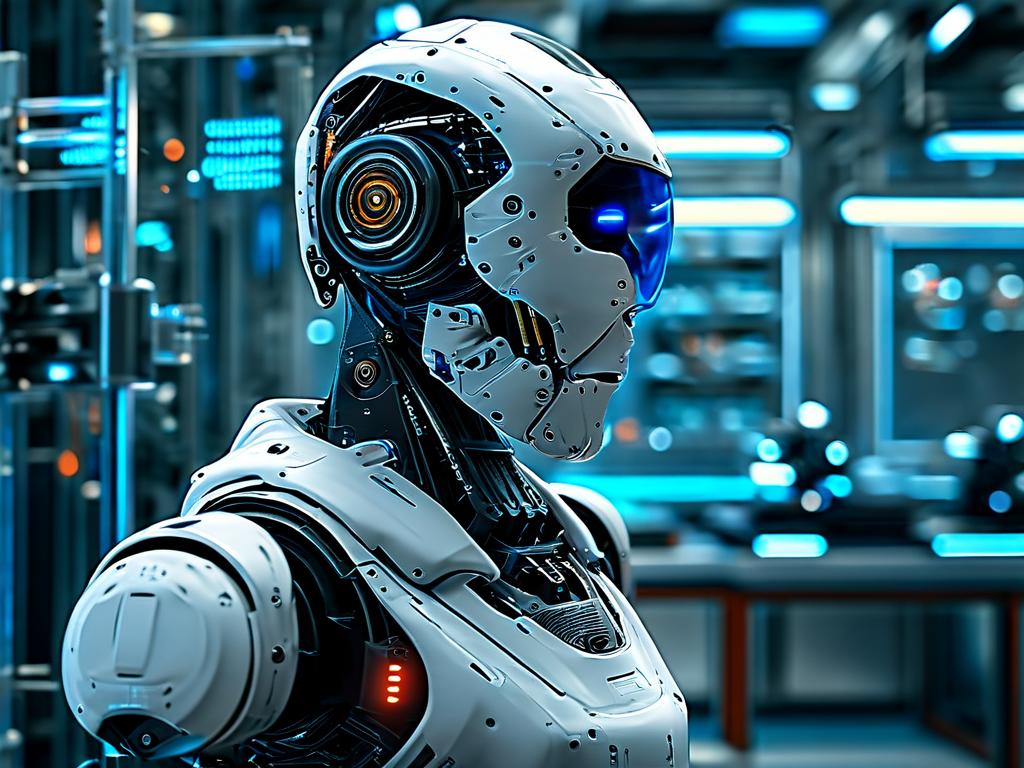

Modern grid inspection robots leverage a combination of advanced hardware and software to perform tasks previously reliant on human labor. Equipped with high-resolution cameras, LiDAR sensors, and thermal imaging systems, these robots can detect faults such as overheated transformers, corroded conductors, or damaged insulators with precision. For example, a robot deployed on high-voltage transmission lines uses AI algorithms to analyze real-time data, identifying anomalies that might elude the human eye. Additionally, some models incorporate drones for aerial inspections, enabling rapid coverage of vast areas—a task that would take human crews days to complete.

A key innovation in this field is the development of autonomous navigation systems. By integrating GPS, inertial measurement units (IMUs), and machine learning, robots can traverse challenging terrains—from dense forests to urban substations—without constant human intervention. This autonomy reduces operational downtime and minimizes risks to personnel, particularly in hazardous environments prone to extreme weather or electrical hazards.

Case Studies: Real-World Applications

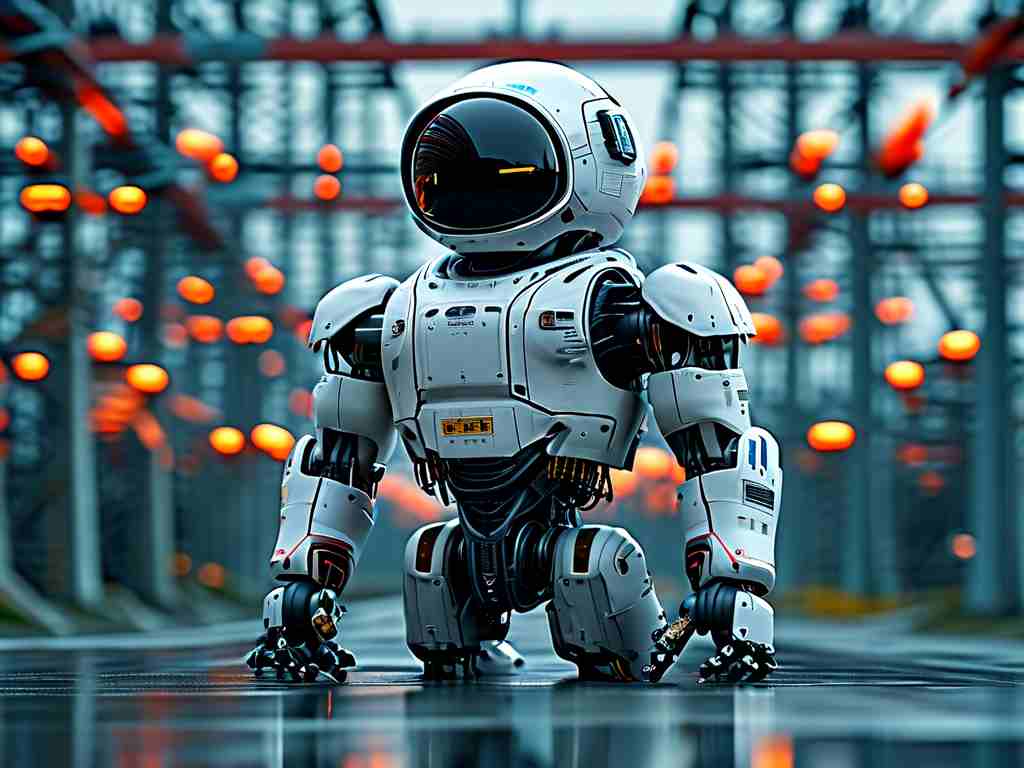

Several utility companies worldwide have adopted grid inspection robots to enhance operational reliability. In one notable case, a European energy provider deployed quadrupedal robots to inspect underground cable tunnels. These four-legged machines, resembling robotic dogs, navigated narrow passages and uneven surfaces while streaming live video feeds to engineers. The project reported a 40% reduction in inspection time and a 30% decrease in accident rates compared to manual methods.

Similarly, a North American utility company implemented drone-based inspection systems for its rural power lines. The drones, equipped with multispectral cameras, identified vegetation encroachment near transmission lines—a common cause of wildfires. By automating this process, the company achieved a 90% accuracy rate in risk prediction and reduced vegetation management costs by 25%.

Challenges and Future Directions

Despite their advantages, grid inspection robots face technical and regulatory hurdles. Battery life remains a limitation for prolonged missions, especially in remote areas. Researchers are exploring hybrid power systems, such as solar-charging modules, to extend operational endurance. Another challenge is data overload; robots generate terabytes of visual and sensor data, necessitating robust cloud-based analytics platforms to extract actionable insights.

Looking ahead, the convergence of 5G connectivity and edge computing promises to address these issues. Real-time data processing at the "edge" of networks—closer to the robots—could reduce latency and bandwidth demands. Meanwhile, collaborative robotics (cobots) are emerging as a trend, where humans and machines work in tandem. For instance, a technician might oversee multiple robots during a substation inspection, prioritizing flagged issues for immediate attention.

Economic and Environmental Impact

The adoption of inspection robotics also aligns with global sustainability goals. By preventing unplanned outages through proactive maintenance, utilities reduce energy waste and carbon emissions associated with emergency repairs. A study by the International Energy Agency (IEA) estimates that smart grid technologies, including robotics, could cut global CO2 emissions by 1.2 gigatons annually by 2040. Furthermore, the reduced need for heavy machinery in inspections lowers fuel consumption and noise pollution in ecologically sensitive areas.

From an economic perspective, the initial investment in robotics is offset by long-term savings. A utility company in Asia reported recouping its robotics expenditure within three years through lowered labor costs and improved grid uptime. As technology scales, prices for robotic systems are expected to decline, making them accessible to smaller operators and developing nations.

Grid inspection robotics represents a transformative force in the energy sector, blending cutting-edge technology with practical utility needs. While challenges persist, ongoing innovations in autonomy, data analytics, and sustainability continue to expand the capabilities of these systems. As grids evolve into interconnected smart networks, robots will play an indispensable role in ensuring reliable, efficient, and safe power delivery for future generations.